|

| May 26, 2020 | Volume 16 Issue 20 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

How to design the optimum hinge

By Christie L. Jones, Market Development Manager, SPIROL International Corporation

There are two primary types of hinges:

There are two primary types of hinges:

- A free-fit hinge has little to no friction or drag when the latch or handle is rotated. Hinge components are "free" to rotate independent of one another.

- A friction-fit hinge requires interference to prevent free rotation of components relative to one another. Depending on design intent, resistance can vary from a slight drag to a value sufficient to maintain the fixed position of components anywhere in their full range of rotation.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance, designers should observe some simple design guidelines.

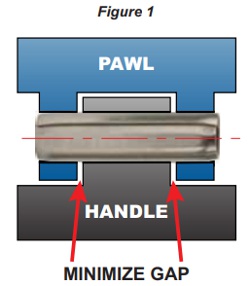

Regardless which pin type is used, the gap between hinged components should be minimized to reduce clearance and avoid bending of the pin (Figure 1).

FREE-FIT HINGE

If a free-fit hinge is desired, the Coiled Pin's pre-installed diameter is of negligible importance, as pin diameter is determined by the retaining, or smallest hole(s). Coiled Pins are functional springs, and recovery and retention in free-fit locations must be considered.

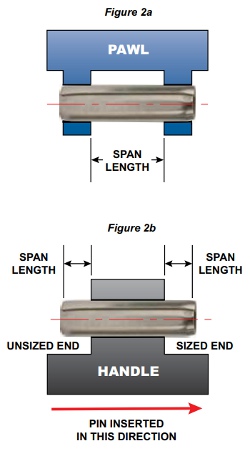

The amount of recovery/retention is dependent upon the diameter of the tight (retaining) hole(s) and the "free span" of the pin. Free span would be defined as the distance a pin passes through a free-fit component. As free span increases, the pin diameter will also increase as it "recovers" a portion of its pre-installed diameter (Figures 2a and 2b).

The amount of recovery/retention is dependent upon the diameter of the tight (retaining) hole(s) and the "free span" of the pin. Free span would be defined as the distance a pin passes through a free-fit component. As free span increases, the pin diameter will also increase as it "recovers" a portion of its pre-installed diameter (Figures 2a and 2b).

It is recommended for better load distribution and closer tolerance hinges that the tight fit of the Coiled Pin be in the outer members of the hinge (Figure 2a). The minimum thickness of the outer members should be 1 to 1 1/2 times the diameter of the pin. If the thickness of the outer members is less than the diameter of the pin, then the tight fit should be in the inside hole.

To design a free-fit hinge, first establish maximum hole size in the retaining component (tight fit). Insert the Coiled Pin into the retaining component and measure the free diameter of the pin at the center of the span. Add a factor to provide some clearance for the rotating member, usually .001 in. (0.02 mm) to establish the minimum diameter of the free hole. Then add the required production tolerance to assign the maximum diameter of the free hole.

If the tight fit is on the inside member of the assembly, as the pin is installed there becomes a sized and an unsized end of the pin (Figure 2b). The end of the pin that has not been inserted through the hole is larger than the end that has been sized by the hole. Therefore, measure the diameter of the unsized end to determine the minimum diameter of the free hole in the outside members.

FRICTION-FIT HINGE

SPIROL Coiled Pins are available in light, standard, and heavy-duty designs.

In a friction-fit hinge, all of the holes should be sized identically within the assigned tolerances. If the manufacturer is unable to maintain the same hole size within each component, the tolerance should be split between the components. It is most common to assign the smaller half of the tolerance to the outside holes and larger half to the inside hole.

The Coiled Pin simplifies design, as there is no need to incorporate misalignment between holes to achieve friction, as is the case with rigid Solid Pins. Coiled Pins perform best when installed in straight, properly aligned holes. The Coiled Pin's spring characteristics can be used to achieve exceptional performance and maintain desired fit and function throughout the life of the product.

Although this article offers general design guidelines, it is recommended that Application Engineers who specialize in fastening and joining be consulted to ensure the optimum hinge design is employed for each application.

Learn more about SPIROL Coiled Spring Pins here.

Published May 2020

Rate this article

View our terms of use and privacy policy