|

| April 23, 2013 | Volume 09 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Extreme miniaturization:

7 devices in one chip navigate without GPS

The U.S. military relies on the space-based Global Positioning System (GPS) to aid air, land, and sea navigation. Like the GPS units in many automobiles today, a simple receiver and some processing power is all that is needed for accurate navigation.

But what if the GPS satellites suddenly became unavailable due to malfunction, enemy action, or simple interference, such as driving into a tunnel? Unavailability of GPS would be inconvenient for drivers on the road, but could be disastrous for military missions. DARPA is working to protect against such a scenario, and an emerging solution is much smaller than the navigation instruments in today's defense systems.

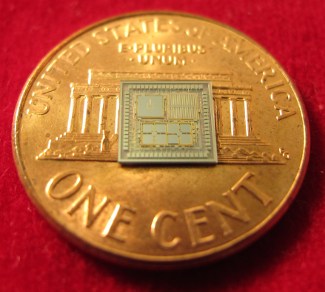

DARPA researchers at the University of Michigan have made significant progress with a timing and inertial measurement unit (TIMU) that contains everything needed to aid navigation when GPS is temporarily unavailable. The single-chip TIMU prototype contains a six-axis IMU (three gyroscopes and three accelerometers) and integrates a highly accurate master clock into a single miniature system that is much smaller than a penny. This chip integrates breakthrough devices (clocks, gyroscopes, and accelerometers), materials, and designs from DARPA's Micro-Technology for Positioning, Navigation, and Timing (Micro-PNT) program.

Three pieces of information are needed to navigate between known points A and B with precision: orientation, acceleration, and time. This new chip integrates state-of-the-art devices that can measure all three simultaneously. The elegant design is accomplished through new fabrication processes in high-quality materials for multi-layered, packaged inertial sensors and a timing unit, all in a tiny 10-mm3, package. Each of the six microfabricated layers of the TIMU is only 50 microns thick, approximately the thickness of a human hair. Each layer has a different function, akin to floors in a building.

"Both the structural layer of the sensors and the integrated package are made of silica," says Andrei Shkel, DARPA program manager. "The hardness and the high-performance material properties of silica make it the material of choice for integrating all of these devices into a miniature package. The resulting TIMU is small enough and should be robust enough for applications [when GPS is unavailable or limited for a short period of time] such as personnel tracking, handheld navigation, small-diameter munitions, and small airborne platforms."

The goal of the Micro-PNT program is to develop technology for self-contained, chip-scale inertial navigation and precision guidance. Other recent breakthroughs from Micro-PNT include new microfabrication methods and materials for inertial sensors.

New fabrication methods

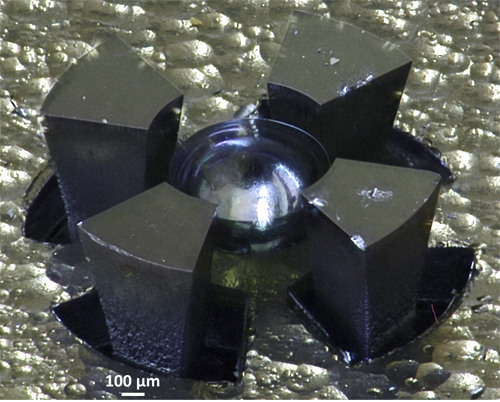

The first phase of Micro-PNT's Microscale Rate Integrating Gyroscope (MRIG) program focused on 3D microfabrication methods using nontraditional materials, such as bulk metallic glasses, diamond, and ultra-low-expansion glass. Small 3D structures such as toroids, hemispheres, and wineglass-shaped structures were successfully fabricated, shifting away from the 2D paradigm of current state-of-the-art microgyroscopes.

These microscale inertial sensors work like Foucault pendulums commonly found in museums. The swinging direction of the pendulum slowly changes as the Earth rotates. Instead of a swinging pendulum, microscale inertial sensors send out vibrations across the surface of a 3D structure. The precession of the standing wave is measured, and any changes reflect a change in orientation. Among the several new fabrication methods created by DARPA to work with these microscale inertial sensors are:

Glass-blowing

[Image: University of Michigan]

Blown quartz

[Image: Georgia Tech]

Similar to glass blowing, quartz blowing can be used to make an even more symmetric structure. Researchers developed fabrication techniques needed to heat quartz to 1,700 deg C (a typical softening point for glass is about 800 deg C) and to then cool it rapidly. The fabrication can be performed in large-quantity batches, producing hundreds of devices on a single wafer.

Atomic layering of diamond

[Image: University of California, Irvine]

Layering diamond over a blown structure or depositing CVD diamond in a micro-well on the substrate have been shown to be effective, promising methods for creating highly symmetric, accurate 3D inertial-sensor structures.

"These new fabrication methods were thought to be unrealistic just a few years ago," says Andrei Shkel, the DARPA program manager.

"As work continues, DARPA hopes these new technologies will enable large-scale production of navigation-grade microscale inertial sensors," adds Shkel. "Production of 3D inertial sensors with these new techniques would cost about the same as today's integrated circuit, making them orders of magnitude smaller, cheaper, and more capable than current microgyroscopes."

Source: DARPA

Published April 2013

Rate this article

View our terms of use and privacy policy