|

| June 04, 2013 | Volume 09 Issue 21 |

Software News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Find test data issues faster: AI Anomaly Detector

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

Learn more.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

How a BattleBot was built using Onshape

Learn how RoboGym Robotics, a veteran BattleBots team, said goodbye to Solidworks and took their design game to the next level using Onshape, the cloud-native, all-in-one CAD and PDM solution. RoboGym was able to analyze key components of their Roundhouse BattleBot like its armor and weapon bar, run simulations, collaborate, iterate, and optimize their design to its fullest.

Learn how RoboGym Robotics, a veteran BattleBots team, said goodbye to Solidworks and took their design game to the next level using Onshape, the cloud-native, all-in-one CAD and PDM solution. RoboGym was able to analyze key components of their Roundhouse BattleBot like its armor and weapon bar, run simulations, collaborate, iterate, and optimize their design to its fullest.

Read this informative Onshape blog.

Trick to measuring angles in SOLIDWORKS

Learn from the pros at TriMech how to take angle measurements easily in SOLID-WORKS. TriMech has an entire YouTube channel dedicated to SOLIDWORKS tips, and the company is excellent at training too.

Learn from the pros at TriMech how to take angle measurements easily in SOLID-WORKS. TriMech has an entire YouTube channel dedicated to SOLIDWORKS tips, and the company is excellent at training too.

View the video.

COMSOL Multiphysics Version 6.2 is here

COMSOL Multiphysics Version 6.2 introduces faster solvers for turbulent fluid flow, electric motors, and room acoustics. It also brings data-driven surrogate model functionality for creating multiphysics-based digital twins and building fast and accurate standalone simulation apps. Get the full details of what's new in the latest version.

COMSOL Multiphysics Version 6.2 introduces faster solvers for turbulent fluid flow, electric motors, and room acoustics. It also brings data-driven surrogate model functionality for creating multiphysics-based digital twins and building fast and accurate standalone simulation apps. Get the full details of what's new in the latest version.

Learn more.

17 ways SOLIDWORKS 2024 helps you work faster

SOLIDWORKS 2024 helps designers and engineers work faster than ever. Learn all about improvements to core 3D CAD modeling features, new 3D modeling techniques, and graphical and software performance boosts that will help you get your parts made and your products developed in record time.

SOLIDWORKS 2024 helps designers and engineers work faster than ever. Learn all about improvements to core 3D CAD modeling features, new 3D modeling techniques, and graphical and software performance boosts that will help you get your parts made and your products developed in record time.

View the video.

6 tips to streamline workflow in Mastercam 2024

Mastercam 2024 CAD/CAM software has been intentionally upgraded to make programming fast and easy. It prioritizes streamlining workflow so that the entire machining process -- from design to QC -- is as efficient as possible. Learn how to maximize the benefits of Mastercam 2024, including special toolpaths, easier hole-making operations, wireframe shortcuts, and more.

Mastercam 2024 CAD/CAM software has been intentionally upgraded to make programming fast and easy. It prioritizes streamlining workflow so that the entire machining process -- from design to QC -- is as efficient as possible. Learn how to maximize the benefits of Mastercam 2024, including special toolpaths, easier hole-making operations, wireframe shortcuts, and more.

Read this informative Mastercam blog.

How CT data analysis is helping TE Connectivity reach their goal of end-to-end quality inspection

In a bid to cut their mold and part development process to 25% of the time it took in the past, TE Connectivity has taken ambitious steps to interconnect design and simulation with quality measurement. Learn how the company, in collaboration with PTC (Creo) and Volume Graphics, has worked to ensure as-designed parts match as-manufactured parts as early in the process as possible. An in-depth and illuminating read.

In a bid to cut their mold and part development process to 25% of the time it took in the past, TE Connectivity has taken ambitious steps to interconnect design and simulation with quality measurement. Learn how the company, in collaboration with PTC (Creo) and Volume Graphics, has worked to ensure as-designed parts match as-manufactured parts as early in the process as possible. An in-depth and illuminating read.

Read the full article.

State-of-the-art mesh morphing technology for super optimization: Ansys and RBF Morph join forces

After a long and successful OEM partnership with Ansys, mesh morphing pioneer RBF Morph has two proprietary products featured among the world simulation leader's offerings: Ansys RBF Morph Fluids and Ansys RBF Morph Structures. Thanks to mesh morphing, companies can substantially reduce computational time while performing highly automated design optimization analysis, increasing products' reliability and performance while cutting costs, delivery time, and environmental impact.

After a long and successful OEM partnership with Ansys, mesh morphing pioneer RBF Morph has two proprietary products featured among the world simulation leader's offerings: Ansys RBF Morph Fluids and Ansys RBF Morph Structures. Thanks to mesh morphing, companies can substantially reduce computational time while performing highly automated design optimization analysis, increasing products' reliability and performance while cutting costs, delivery time, and environmental impact.

Read the full article.

Top Tech Tip: Creating drafts with the rib feature in Onshape

Ribs are used to add stiffness and strength to parts without adding excessive weight or increasing wall thickness -- most commonly in molded parts that require a draft angle so the part can release from the mold. See the basics of how this is done in Onshape, which features the power of cloud computing, real-time collaboration tools, and a built-in PDM system -- all for the same price as CAD.

Ribs are used to add stiffness and strength to parts without adding excessive weight or increasing wall thickness -- most commonly in molded parts that require a draft angle so the part can release from the mold. See the basics of how this is done in Onshape, which features the power of cloud computing, real-time collaboration tools, and a built-in PDM system -- all for the same price as CAD.

Learn more.

How to design a spoon with subdivision modeling: SOLIDWORKS xShape

Learn how to design a spoon with SOLIDWORKS xShape, which is found in 3D Sculptor on the 3DEXPERI-ENCE platform. xShape is a next-gen subdivision modeling tool that runs entirely in your browser and takes a freeform approach to creating complex shapes and surfaces. You can design 100% in the cloud or seamlessly integrate your xShape models with your SOLIDWORKS designs. Follow along with this 7-minute tutorial to see what it's all about.

Learn how to design a spoon with SOLIDWORKS xShape, which is found in 3D Sculptor on the 3DEXPERI-ENCE platform. xShape is a next-gen subdivision modeling tool that runs entirely in your browser and takes a freeform approach to creating complex shapes and surfaces. You can design 100% in the cloud or seamlessly integrate your xShape models with your SOLIDWORKS designs. Follow along with this 7-minute tutorial to see what it's all about.

View the video.

What's new in Onshape?

Check out the latest updates to Onshape, the cloud-native product development platform that delivers professional-grade CAD capabilities with next-gen product data management. New features include customizable keyboard shortcuts, better BOM navigation, improved drawing tools, and new Learning Center content. With Onshape, users can innovate quickly while simultaneously or asynchronously collaborating with other stakeholders on any web-connected device.

Check out the latest updates to Onshape, the cloud-native product development platform that delivers professional-grade CAD capabilities with next-gen product data management. New features include customizable keyboard shortcuts, better BOM navigation, improved drawing tools, and new Learning Center content. With Onshape, users can innovate quickly while simultaneously or asynchronously collaborating with other stakeholders on any web-connected device.

View the video.

Open-access learning center for multiphysics modeling

COMSOL, the developer of the COMSOL Multiphysics simulation software, has introduced a new online resource that provides no-cost, open access to modeling and simulation learning material across all areas of physics. Designed with the user in mind, the Learning Center offers a single entry point for users of all skill levels, where courses, articles, and videos present a clear path for learning how to use COMSOL Multiphysics for modeling and simulation.

COMSOL, the developer of the COMSOL Multiphysics simulation software, has introduced a new online resource that provides no-cost, open access to modeling and simulation learning material across all areas of physics. Designed with the user in mind, the Learning Center offers a single entry point for users of all skill levels, where courses, articles, and videos present a clear path for learning how to use COMSOL Multiphysics for modeling and simulation.

Check out the COMSOL Learning Center.

New GrabCAD Print Pro software: Boost 3D-printing productivity

Stratasys, a leader in polymer 3D printing, recently announced the upcoming launch of its new GrabCAD Print Pro software, which has been designed to improve printed-part accuracy, reduce waste, and shorten time to part. GrabCAD Print software manages the print preparation process for Stratasys 3D printers.

Stratasys, a leader in polymer 3D printing, recently announced the upcoming launch of its new GrabCAD Print Pro software, which has been designed to improve printed-part accuracy, reduce waste, and shorten time to part. GrabCAD Print software manages the print preparation process for Stratasys 3D printers.

Read the full article.

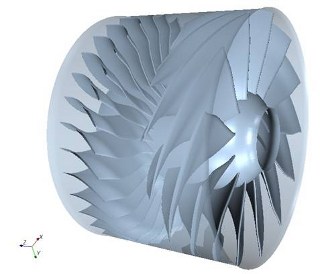

3D inverse design helps military OEM develop unique cooling fans

A U.S.-based defense contractor, an original equipment manufacturer (OEM) of life support systems (LSS) for military applications, had a need for a custom fan to be integrated in its product line. With TURBOdesign1 from Advanced Design Technology (ADT), the company was able to bring the fan design process in-house and cut design time as well as production cost.

In developing the fan, engineers were challenged to develop a large air-flow-volume, low-pressure fan characteristic with high air velocities over the stator blades. In order to achieve the best aerodynamic efficiency, it was required to avoid separation at the stator while recovering the static pressure. No existing standard design was known that could satisfy the requirements to efficiency, size, and operating speed.

Reducing the fan noise was an additional design objective. Certain rotor design features were desirable to minimize fan noise: forward sweep of the rotor blades, plus reduced chord length at the shroud were to eliminate the possibility of vortices shedding off from the suction side of the rotor blades and hitting the next blade pressure side close to the trailing edge. Another desirable feature was positive blade stacking at the rotor blade tip to minimize losses and noise associated with the tip clearance.

Originally, the company evaluated several conventional fan design approaches, including all the available commercial codes for design of turbomachinery based on a direct design approach. The evaluation criteria included computer system requirements and associated hardware costs, the number of engineers needed to be involved in the design process, and the learning curve to produce new designs with a high level of confidence. ADT's TURBOdesign1 software came out the winner, in part because it did not require special hardware and, after just three weeks of initial training, engineers were able to tackle their first fan design case.

The design team used ADT's TURBOdesign1 3D inverse design code to introduce these new features and achieve rotor blade loading that produces the required flow and pressure rise at the lowest shaft power with a sufficient stall margin.

After completing and testing two different axial fan designs, the company engineers became more confident that their next designs would be successful. Examples of the resulting geometries of the stage are shown in Figures 1 and 2.

Figure 1. The resulting geometry of one of the axial flow stages designed by TURBOdesign1.

Figure 2. The final hardware model.

ADT's TURBOdesign1 inverse design code, used together with CD Adapco Star CCM+ computational fluid dynamics (CFD) software, has proven to satisfy all of the new design objectives.

"We found ourselves using all the features implemented in the TURBOdesign1 code," said the company's aerodynamics engineer. "In addition to specifying meridional geometry and blade loading, having the ability to specify custom blade thickness, stacking location, and stacking profiles was very useful in achieving good aerodynamic designs."

TURBOdesign1 output data was exported to a spreadsheet, and additional design parameters, like diffusion factor for axial fans, were evaluated during the design procedure. This gave the designers an even higher level of confidence early in the design process, before taking it to CFD for evaluation and prototype construction and testing.

The use of ADT's TURBOdesign1 software made it possible to design an entirely new cooling fan from scratch, starting only from design requirements. In the process, the company was able to eliminate the costs of using outside consultants, reduce the lead time for new turbo-machinery designs of this type, and produce its own designs in-house that are best suited to its application needs.

"We cannot put a dollar figure on our new ability to design our own fans," said one design engineer. "But, in our opinion, it's invaluable."

Want more information? Click below.

Source: Advanced Design Technology (ADT)

Published June 2013

Rate this article

View our terms of use and privacy policy