|

| February 11, 2014 | Volume 10 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Integrated vehicle simulation

Model-based systems engineering (MBSE) using open standards provides a better understanding of the complex interactions at work in modern vehicle design

By Bob Cramblitt

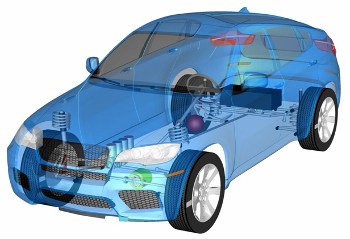

Model-based systems engineering helps engineers analyze complex subsystem interdependencies in hybrid vehicles.

More than at any time in automotive history, performance factors are based on interdependencies that ripple throughout the vehicle, particularly for hybrids that combine combustion engines with electric propulsion systems.

Modelon, a worldwide supplier of products and services for system design and optimization, recently used a model-based systems engineering (MBSE) approach to evaluate and balance multiple performance attributes for an e4WD hybrid car. MBSE-based technologies are used by major automotive manufacturers such as Audi, BMW, Daimler, Toyota, Volkswagen, Volvo, and others.

The MBSE approach is defined by three basic characteristics:

- multi-domain, where the physics from several different vehicle systems can be simulated within the same models;

- multi-fidelity, where models of different sizes and complexity can be used according to specific analysis needs; and

- wide deployment, where models can be exported outside their original environments and used for a wide range of engineering evaluations.

The key enablers in Modelon's study were Dymola, software from Dassault Systemes that uses the open-standard Modelica language to model and simulate the behavior and performance of systems with complex interactions; and FMI (Functional Mockup Interface), an open-standard interface that enables models called FMUs to be integrated into multiple simulation environments.

The vehicle models use Modelica libraries from Modelon that enable plug-and-play modeling with a variety of subsystem configurations at different fidelity levels.

Maximizing fuel economy

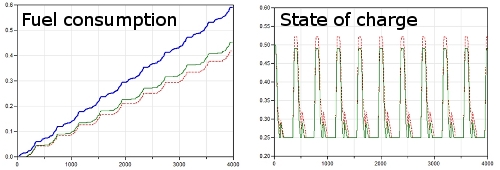

The central selling point of a hybrid vehicle is fuel economy. A hybrid achieves energy savings by synchronizing the engine, electric machines, and battery for maximum efficiency. Further savings are gained from optimizing the use of parasitic power throughout the vehicle. The Modelon study compared three different powertrain architectures:

- Using a downsized, turbocharged engine.

- Integrating a flywheel into the design.

- Integrating an electric motor/generator with a battery.

The simulation results below show that configurations two and three yield better fuel economy due to regenerative braking.

Results also showed that energy management for hybrid vehicles is sensitive to battery characteristics, making it important to capture how battery configurations perform when interacting with mechanical, thermal, and electrical subsystems.

Thermal interactions

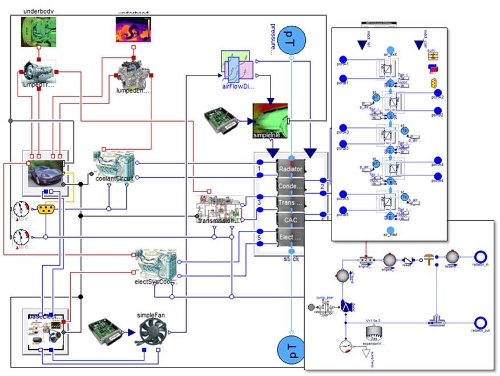

Thermal system design also plays a major role in energy management and performance of hybrid vehicles. Modelon simulated the e4WD thermal system in conjunction with other vehicle dynamics to gain a complete picture of performance.

In the first case, a high-voltage battery was passively cooled through convective heat transfer from the vehicle's underbody. In the second case, the high-voltage battery was isolated from the underbody but included an active fluid coolant loop in the heat-exchanger stack.

Thermal system design plays a major role in energy management and performance of a hybrid vehicle.

The simulation results showed the benefits of using model-based systems engineering to reveal the complex multi-domain interactions among subsystems.

In the passive case, the battery recorded high internal temperatures due to limited heat dispersion to the surrounding air. Heat from the battery also increased the transmission oil temperature, since the transmission was connected to the car's underbody.

In the second case, active cooling of the battery reduced temperatures and allowed more efficient operation and charging.

Driving performance

Partial electric propulsion in hybrid vehicles offers new opportunities to improve the driving experience, but it also introduces new complexities.

Acceleration must consider traction blending of the combustion engine and electric machines combined with front and rear torque distribution. Deceleration must take into account the split between mechanical friction brakes and electric machines. Both cases must fit into the energy management strategy and requirements for drivability, performance, and safety.

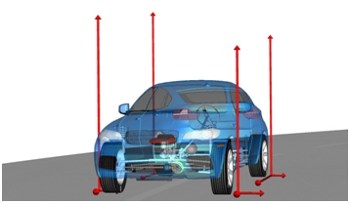

Animation still image from the driving performance tests. Vectors indicate tire forces.

The Modelon study used a virtual skid-pad with a 50-meter radius and the friction lowered to 70 percent of nominal. The driver started from a standstill, released the brakes and then pressed the accelerator pedal.

Results from the acceleration and velocity profile showed the e4WD outperforming the original vehicle, mainly due to improved grip and greater torque from the standstill position. The feel of the e4WD would be much better as well, due to faster response time, smoother acceleration, and lower jerk. The model-based systems engineering approach enables designers to balance physical systems with controls to reach the optimal blend of overall performance.

Wider model deployment

The ability to export models outside the original software used to develop them opens up the possibility of widespread model deployment throughout the enterprise.

The e4WD vehicle model with the driver, for example, was imported into Simulink using the FMI Toolbox for MATLAB. This allows control designers to test and evaluate their designs within their familiar working environment. And it goes both ways: The controller from Simulink can be exported as an FMU for import back into Dymola.

A standalone FMU enables engineers to use their familiar analysis tools to understand details of a subsystem or the effects of a design change. Different component sizes for the e4WD vehicle were evaluated, for example, in Excel using the FMI Add-in for Excel.

Finally, a full vehicle can be imported into a driver-in-the-loop (combining a model with virtual human interaction) environment using the FMI Library. Coupling a model exported with automated optimizations for fixed-step solvers with a program such as rFactor Pro allows complex, high-fidelity models to be run in real-time simulations.

The benefits of integration and sharing

Model-based systems engineering using Modelica and FMI gives engineers a comprehensive picture of the complex interactions among different vehicle systems early in the design process. The result? Better designs, greater performance, and major cost savings by moving analysis forward in the product development process and reducing downstream physical prototypes.

Sidebar: Modelica and FMI benefits

Modelica and FMI technologies enable engineering organizations to:

- Simulate all relevant physical domains and their interaction in the same system model.

- Create plug-and-play compatible component and system models.

- Use system architectures for rapid model configuration.

- Perform component-based evaluations.

- Work with different fidelity levels within the same framework.

- Export models to other tools and applications.

About the author

Bob Cramblitt is a freelancer who writes about computer-aided technologies that help organizations achieve the holy trilogy of faster, better, and cheaper.

Published February 2014

Rate this article

View our terms of use and privacy policy