|

| February 25, 2014 | Volume 10 Issue 08 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Durable, full redundant angle sensors for automotive and off-highway

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Learn more.

Great design: Handle with integrated lighting/signaling

Signaling and indicator lights, switches, and buttons -- elements that hardly any machine can do without. The new JW Winco cabinet U-handle EN 6284 integrates all these functions into a single, compact element. The new U-handle is designed to enhance the operation of systems and machines. It features an integrated button and a large, colored, backlit area on the handle. These elements can be used individually or in combination, providing a versatile tool for system control and process monitoring that can be seen from across the room.

Signaling and indicator lights, switches, and buttons -- elements that hardly any machine can do without. The new JW Winco cabinet U-handle EN 6284 integrates all these functions into a single, compact element. The new U-handle is designed to enhance the operation of systems and machines. It features an integrated button and a large, colored, backlit area on the handle. These elements can be used individually or in combination, providing a versatile tool for system control and process monitoring that can be seen from across the room.

Learn more.

World's most popular 3D multisensor metrology systems get next-gen addition

Offered in two benchtop and two floor-model options to handle nearly any size part, the SmartScope M-Series systems from Optical Gaging Products usher in the next generation of enhancements in image accuracy, optics, and throughput to the world's most popular 3D multisensor video measurement platform. SmartScope M-Series features fixed optics with a 20-megapixel camera and proprietary Virtual Zoom, combined with advanced sensors, illumination, and accessories, to achieve class-leading optical measurement speeds. Lots more features.

Offered in two benchtop and two floor-model options to handle nearly any size part, the SmartScope M-Series systems from Optical Gaging Products usher in the next generation of enhancements in image accuracy, optics, and throughput to the world's most popular 3D multisensor video measurement platform. SmartScope M-Series features fixed optics with a 20-megapixel camera and proprietary Virtual Zoom, combined with advanced sensors, illumination, and accessories, to achieve class-leading optical measurement speeds. Lots more features.

Learn more.

SOLIDWORKS Tips: 3 easy ways to focus on your model

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

View the video.

Push-pull transformer drivers for automotive power supplies

Nexperia's AEC-Q100 qualified, push-pull transformer drivers (NXF6501-Q100, NXF6505A-Q100, and NXF6505B-Q100) enable the design of small, low-noise, and low-EMI isolated power supplies for a range of automotive applications such as traction inverters and motor control, DC-DC converters, battery management systems, and on-board chargers in EVs. Also suitable for industrial applications such as telecommunications, medical, instrumentation, and automation equipment.

Nexperia's AEC-Q100 qualified, push-pull transformer drivers (NXF6501-Q100, NXF6505A-Q100, and NXF6505B-Q100) enable the design of small, low-noise, and low-EMI isolated power supplies for a range of automotive applications such as traction inverters and motor control, DC-DC converters, battery management systems, and on-board chargers in EVs. Also suitable for industrial applications such as telecommunications, medical, instrumentation, and automation equipment.

Learn more.

Mini linear position sensor for drones, robots, aero, more

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

Learn all the specs.

What is a Heatric Printed Circuit Heat Exchanger?

According to Parker Hannifin, "A Printed Circuit Heat Exchanger is a robust, corrosion-resistant, high-integrity plate-type heat exchanger manufactured using diffusion bonding." Learn about the technology and why Heatric, a Parker brand, "can manufacture a unit up to 85% smaller and lighter than traditional technologies such as shell and tube heat exchangers."

According to Parker Hannifin, "A Printed Circuit Heat Exchanger is a robust, corrosion-resistant, high-integrity plate-type heat exchanger manufactured using diffusion bonding." Learn about the technology and why Heatric, a Parker brand, "can manufacture a unit up to 85% smaller and lighter than traditional technologies such as shell and tube heat exchangers."

Read this informative Parker blog.

Tech Tip: Mastering sheet metal bend calculations in Onshape

Mastering bend calculations in sheet metal design is a key skill that can impact the accuracy and manufactur-ability of your designs significantly. Explore the various options available to become a pro in this Onshape Tech Tip: K Factor, bend allowance, and bend deduction, with guidance on when each should be used. You may learn something even if you don't use this software.

Mastering bend calculations in sheet metal design is a key skill that can impact the accuracy and manufactur-ability of your designs significantly. Explore the various options available to become a pro in this Onshape Tech Tip: K Factor, bend allowance, and bend deduction, with guidance on when each should be used. You may learn something even if you don't use this software.

Read the Onshape blog.

Seifert thermoelectric enclosure coolers from AutomationDirect beat the heat

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

Raspberry Pi Pico 2: Microcontroller board with 2x flash memory

Raspberry Pi's Pico low-cost, high-performance microcontroller board with flexible digital interfaces is now being offered as a full second-generation product, complete with twice the on-board flash memory, higher performance, lower power consumption, and greater security.

Raspberry Pi's Pico low-cost, high-performance microcontroller board with flexible digital interfaces is now being offered as a full second-generation product, complete with twice the on-board flash memory, higher performance, lower power consumption, and greater security.

Read the full article.

Free-Core vs. Spring-Loaded LVDT position sensors

Linear Variable Differential Transformers are electro-mechanical devices used in many industrial applications to measure the displacement or position of an object. They convert the linear position or motion of a measured object into an electrical output that is displayed on a local readout or input into a programmable logic controller as part of an automated process control system. LVDTs come in two core configurations -- free-core and spring-loaded -- but do you know what the differences are?

Linear Variable Differential Transformers are electro-mechanical devices used in many industrial applications to measure the displacement or position of an object. They convert the linear position or motion of a measured object into an electrical output that is displayed on a local readout or input into a programmable logic controller as part of an automated process control system. LVDTs come in two core configurations -- free-core and spring-loaded -- but do you know what the differences are?

Read the full NewTek Sensor Solutions article.

New sensor listens to fuel for optimum marine diesel engine performance

Condition monitoring expert CM Technologies has added a fuel injection acoustic emission sensor to its proprietary PREMET X range of two- and four-stroke diesel engine performance indicators for marine use. The device allows engineers to monitor the acoustic signature of a diesel engine's fuel injection system to detect any problems with fuel injectors, nozzles, and pumps.

Condition monitoring expert CM Technologies has added a fuel injection acoustic emission sensor to its proprietary PREMET X range of two- and four-stroke diesel engine performance indicators for marine use. The device allows engineers to monitor the acoustic signature of a diesel engine's fuel injection system to detect any problems with fuel injectors, nozzles, and pumps.

Read the full article.

Application Note: Quadcopter propeller torque/thrust testing

The quadcopter's four propellers are designed to work in conjunction with each other to ensure there are no torque imbalances that could send the vehicle spinning out of control. But just how would a professional developer or hobbyist perform accurate propeller torque and thrust testing? Advanced sensor expert FUTEK has the answer.

The quadcopter's four propellers are designed to work in conjunction with each other to ensure there are no torque imbalances that could send the vehicle spinning out of control. But just how would a professional developer or hobbyist perform accurate propeller torque and thrust testing? Advanced sensor expert FUTEK has the answer.

Read the full article.

New enclosure heat exchanger options

Automation-Direct has added new Saginaw Enviro-Therm® air-to-air heat exchangers that use an enclosure's ambient air and either heat pipes or aluminum plate to transfer heat from inside the enclosure to the external environment. Since the ambient air is the cooling medium, the need for refrigerant is eliminated. Features include corrosion-resistant internal components, a filterless design for maximum cooling and reduced clogging, simple installation, and a programmable digital controller.

Automation-Direct has added new Saginaw Enviro-Therm® air-to-air heat exchangers that use an enclosure's ambient air and either heat pipes or aluminum plate to transfer heat from inside the enclosure to the external environment. Since the ambient air is the cooling medium, the need for refrigerant is eliminated. Features include corrosion-resistant internal components, a filterless design for maximum cooling and reduced clogging, simple installation, and a programmable digital controller.

Learn more.

World's smallest-width floating connector simplifies automotive installation

Hirose has developed a space-saving, board-to-board connector that combines floating functionality and miniature size to meet automotive specifications. The BM54 Series boasts the world's smallest-width class for its category, a 0.4-mm pitch, and a stacking height of 3.0 to 4.5 mm. This connector is ideal for PCBs with multiple connector sets and offers a wide floating range of +/- 0.4 mm in the XY direction. By absorbing board misalignment errors, floating simplifies assembly and improves assembly work efficiency. Applications include cameras, displays, millimeter wave radar, and LiDAR systems.

Hirose has developed a space-saving, board-to-board connector that combines floating functionality and miniature size to meet automotive specifications. The BM54 Series boasts the world's smallest-width class for its category, a 0.4-mm pitch, and a stacking height of 3.0 to 4.5 mm. This connector is ideal for PCBs with multiple connector sets and offers a wide floating range of +/- 0.4 mm in the XY direction. By absorbing board misalignment errors, floating simplifies assembly and improves assembly work efficiency. Applications include cameras, displays, millimeter wave radar, and LiDAR systems.

Learn more.

Pomegranate-inspired design solves lithium-ion battery shortcomings

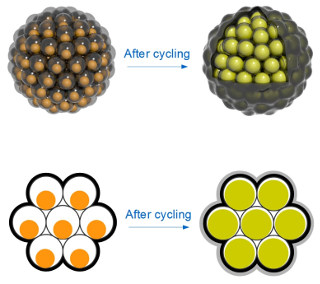

An electrode designed like a pomegranate -- with silicon nanoparticles clustered like seeds in a tough carbon rind -- overcomes several remaining obstacles to using silicon for a new generation of lithium-ion batteries, say its inventors at Stanford University and the Department of Energy's SLAC National Accelerator Laboratory.

A novel battery electrode features silicon nanoparticles clustered like pomegranate seeds in a tough carbon rind. [Illustration by Greg Stewart/SLAC]

"While a couple of challenges remain, this design brings us closer to using silicon anodes in smaller, lighter, and more powerful batteries for products like cell phones, tablets, and electric cars," said Yi Cui, an associate professor at Stanford and SLAC who led the research, reported Feb. 16 in Nature Nanotechnology.

"Experiments showed our pomegranate-inspired anode operates at 97 percent capacity even after 1,000 cycles of charging and discharging, which puts it well within the desired range for commercial operation."

The anode, or negative electrode, is where energy is stored when a battery charges. Silicon anodes could store 10 times more charge than the graphite anodes in today's rechargeable lithium-ion batteries, but they also have major drawbacks: The brittle silicon swells and falls apart during battery charging, and it reacts with the battery's electrolyte to form gunk that coats the anode and degrades its performance.

Over the past eight years, Cui's team has tackled the breakage problem by using silicon nanowires or nanoparticles that are too small to break into even smaller bits and encasing the nanoparticles in carbon "yolk shells" that give them room to swell and shrink during charging.

The new study builds on that work. Graduate student Nian Liu and postdoctoral researcher Zhenda Lu used a microemulsion technique common in the oil, paint, and cosmetic industries to gather silicon yolk shells into clusters, and coated each cluster with a second, thicker layer of carbon. These carbon rinds hold the pomegranate clusters together and provide a sturdy highway for electrical currents.

And since each pomegranate cluster has just one-tenth the surface area of the individual particles inside it, a much smaller area is exposed to the electrolyte, thereby reducing the amount of gunk that forms to a manageable level.

Although the clusters are too small to see individually, together they form a fine black powder that can be used to coat a piece of foil and form an anode. Lab tests showed that pomegranate anodes worked well when made in the thickness required for commercial battery performance.

Top: Silicon nanoparticles are encased in carbon "yolk shells" and clustered like seeds in a pomegranate. Each cluster has a carbon rind that holds it together, conducts electricity, and minimizes reactions with the battery's electrolyte that can degrade performance. Bottom: Silicon nanoparticles swell during battery charging; no space is wasted, and the shells stay intact. [Nian Liu, Zhenda Lu and Yi Cui/Stanford]

While these experiments show the technique works, Cui said, the team will have to solve two more problems to make it viable on a commercial scale: They need to simplify the process and find a cheaper source of silicon nanoparticles. One possible source is rice husks: They're unfit for human food, produced by the millions of tons, and are 20 percent silicon dioxide by weight. According to Liu, they could be transformed into pure silicon nanoparticles relatively easily, as his team recently described in Scientific Reports.

"To me it's very exciting to see how much progress we've made in the last seven or eight years," Cui said, "and how we have solved the problems one by one."

The research team also included Jie Zhao, Matthew T. McDowell, Hyun-Wook Lee, and Wenting Zhao of Stanford. Cui is a member of the Stanford Institute for Materials and Energy Sciences, a joint SLAC/Stanford institute. The research was funded by the DOE Office of Energy Efficiency and Renewable Energy.

SLAC is a multi-program laboratory exploring frontier questions in photon science, astrophysics, particle physics and accelerator research. Located in Menlo Park, CA, SLAC is operated by Stanford University for the U.S. Department of Energy Office of Science.

The Stanford Institute for Materials and Energy Sciences (SIMES) is a joint institute of SLAC National Accelerator Laboratory and Stanford University.

Source: Stanford University

Published February 2014

Rate this article

View our terms of use and privacy policy