|

| March 04, 2014 | Volume 10 Issue 09 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

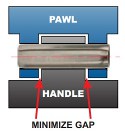

Engineer's Toolbox: How to design the optimum hinge

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Read the full article.

Innovative new robo welding gun

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Learn more.

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

New Standard Parts Handbook from JW Winco

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

Get your Standard Parts Handbook today.

Looking to save space in your designs?

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

View the video.

Top die casting design tips

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

Read the full Xometry article.

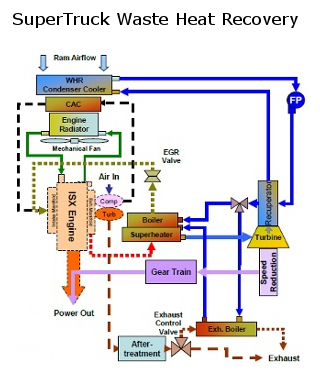

Cummins-Peterbilt SuperTruck gets Modine waste heat recovery heat exchangers

Modine Manufacturing Company, a world leader in thermal innovation, is developing a series of compact heat exchangers designed to capture waste heat from the exhaust stream of a diesel engine and convert this heat into useful power to improve engine efficiency and reduce CO2 emissions.

As part of this development effort, Modine has been involved in a Department of Energy-sponsored program called SuperTruck and has provided these heat exchangers to a Cummins-Peterbilt concept vehicle for comprehensive road testing. During this road testing, the vehicle achieved 10.7 mpg. The truck also demonstrated a 75 percent increase in fuel economy in head-to-head testing over a 24-hr time period compared with a 2009 baseline truck. These results translated to a 43 percent reduction in greenhouse gas emissions and an 86 percent gain in freight efficiency. The vehicle was on display at a recent event in Maryland where President Obama announced that work would begin on the next phase of national greenhouse gas and fuel efficiency requirements for commercial trucks.

The Department of Energy (DOE) initiated the multi-year SuperTruck program in 2010 with the goal of designing a heavy-duty Class 8 truck that achieves a 50 percent improvement in overall freight efficiency. That increase in fuel economy would save about $25,000 annually based on today's diesel fuel prices for a long-haul truck traveling 120,000 miles per year. The DOE set the goal of attaining part of the overall efficiency gains from engine improvements, with the remaining gains coming from other vehicle improvements such as aerodynamics, use of lighter-weight materials, and reduction of friction in the drive train. Class 8 trucks represent only about 4 percent of the on-road vehicles in the United States but are responsible for almost 20 percent of the country's on-road fuel consumption.

The Cummins-Peterbilt collaboration was one of several DOE-selected partner projects. The objectives of this partnership were to develop and demonstrate a highly efficient and clean diesel engine, an advanced Rankine-based waste heat recovery system, an aerodynamic Peterbilt tractor-trailer combination, and an auxiliary power unit (APU) to reduce engine idling. Cummins and Peterbilt selected Modine to provide the heat exchangers for the waste heat recovery system.

The Rankine-based waste heat recovery system operates similarly to a conventional stationary power plant. A power fluid is boiled using the heat from the diesel engine exhaust and is sent to a turbine, which converts this heat into mechanical energy. By recovering this energy from the exhaust, the diesel engine uses less fuel and CO2 emissions are reduced. Multiple heat exchangers are required for this system to operate efficiently.

However, unlike a conventional power plant, these heat exchangers must be miniaturized to fit under the hood and on the chassis of a conventional Class 8 truck. "Our research engineers utilized Modine's technology building blocks to develop highly compact heat exchangers to meet the thermal management and space requirements of this new challenge," says Lawrence Gabbey, Modine Research Engineering Section Manager and Program Manager for the SuperTruck program. "Leveraging the success of this demonstration program, Modine continues to develop this waste heat recovery technology in preparation for future commercial opportunities around the globe in the commercial vehicle and automotive markets."

The Modine SuperTruck front-end cooling module consists of a radiator, charge-air cooler, air-conditioning condenser, and new waste heat recovery condenser. Lower left (in front of the module): stainless steel EGR Boiler-Superheater for the engine. Lower right: aluminum Recuperator. Both additional heat exchangers are part of the waste heat recovery system. This photo depicts six Modine heat exchangers in all. Modine also provides a tailpipe boiler.

"Fuel economy and the reduction of CO2 emissions are two strong technology drivers that will create many opportunities for Modine heat exchanger technology in the future," says Jonathan Wattelet, Modine's Global Director of Research and Technical Services. "The SuperTruck public-private partnership sponsored by the Department of Energy has been an excellent opportunity to leverage our research in areas where longer-term research is too risky to undertake alone. Working with engine and commercial vehicle leaders such as Cummins and Peterbilt has been an outstanding opportunity for Modine to obtain much-needed engine test cell and road testing experience for our newly developed heat exchanger technology."

Want to know more details about the Cummins/Peterbilt SuperTruck project? You can view an in-depth 2012 presentation (PDF) by clicking here.

Source: Modine

Published March 2014

Rate this article

View our terms of use and privacy policy