|

| June 02, 2015 | Volume 11 Issue 21 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

How ball spline coatings enhance performance and extend component life

According to Thomson, "Precision ball splines have gained popularity as an ideal choice for applications that require low-friction linear and rotary motion. These components, which utilize a single splined shaft, enable complex movements in multiple directions." But how do you keep these ball splines performing at their peak for longer? Coatings can do the trick, and Thomson has three of them: black oxide, hard chrome plating, and nickel plating. Learn more about these coatings and which one makes the most sense for your precision ball spline solution.

According to Thomson, "Precision ball splines have gained popularity as an ideal choice for applications that require low-friction linear and rotary motion. These components, which utilize a single splined shaft, enable complex movements in multiple directions." But how do you keep these ball splines performing at their peak for longer? Coatings can do the trick, and Thomson has three of them: black oxide, hard chrome plating, and nickel plating. Learn more about these coatings and which one makes the most sense for your precision ball spline solution.

View the video.

Key factors for ball screw applications

Learn the six key factors that should be considered when specifying ball screw assemblies in motion control applications. PCB Linear gathered a panel of experts in the field of linear motion to concentrate on this important topic -- particularly when it comes to the company's new miniature ball screw product line. Learn about precision and accuracy, orientation, speed and acceleration, duty cycle, linear motion travel, and load capacity. Podcast available too.

Learn the six key factors that should be considered when specifying ball screw assemblies in motion control applications. PCB Linear gathered a panel of experts in the field of linear motion to concentrate on this important topic -- particularly when it comes to the company's new miniature ball screw product line. Learn about precision and accuracy, orientation, speed and acceleration, duty cycle, linear motion travel, and load capacity. Podcast available too.

Read the PCB Linear blog.

3D printer uses pellet extrusion system instead of filament

The latest addition to 3D Systems' industry-leading portfolio of EXT Titan Pellet systems is the EXT 800 Titan Pellet. With a build volume of 800 x 600 x 800 mm, this thermoplastics 3D printer harnesses the speed, reliability, and efficiency of the company's large-format pellet systems in a more compact unit with lower upfront investment. Use this machine to fabricate more modestly sized functional prototypes, tooling, fixtures, sand casting patterns, thermoforming molds, and end-use parts. Markedly faster than competing FFF and FDM printers, and up to 10X reduced material costs compared to filaments.

The latest addition to 3D Systems' industry-leading portfolio of EXT Titan Pellet systems is the EXT 800 Titan Pellet. With a build volume of 800 x 600 x 800 mm, this thermoplastics 3D printer harnesses the speed, reliability, and efficiency of the company's large-format pellet systems in a more compact unit with lower upfront investment. Use this machine to fabricate more modestly sized functional prototypes, tooling, fixtures, sand casting patterns, thermoforming molds, and end-use parts. Markedly faster than competing FFF and FDM printers, and up to 10X reduced material costs compared to filaments.

Learn more.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New flat quarter-turn clamping fastener

IMAO Fixtureworks has expanded its One-Touch Fastener lineup to include a new quarter-turn clamping fastener that features an innovative flat design and is ideal for clamping in limited spaces. The QCFC flat quarter-turn fastener features a recessed body that protrudes only 2 mm from the mounted surface, a knob that rests flush inside the body, visible ON and OFF markings for safety, and an audible click when fully turned to clamped or unclamped position.

IMAO Fixtureworks has expanded its One-Touch Fastener lineup to include a new quarter-turn clamping fastener that features an innovative flat design and is ideal for clamping in limited spaces. The QCFC flat quarter-turn fastener features a recessed body that protrudes only 2 mm from the mounted surface, a knob that rests flush inside the body, visible ON and OFF markings for safety, and an audible click when fully turned to clamped or unclamped position.

Learn more.

Bellows and disc couplings with higher torque capacity

Ruland Manufacturing now offers bellows and double disc couplings with bore sizes up to 1-3/4 in. or 45 mm for use in systems with torque up to 1,400 in.-lb (158 Nm). High-torque applications in precision semiconductor, solar, conveyor, and factory automation applications often use these shaft sizes. Ruland disc and bellows couplings accommodate all forms of misalignment, are zero-backlash, and have a balanced design for reduced vibration at speeds up to 10,000 rpm.

Ruland Manufacturing now offers bellows and double disc couplings with bore sizes up to 1-3/4 in. or 45 mm for use in systems with torque up to 1,400 in.-lb (158 Nm). High-torque applications in precision semiconductor, solar, conveyor, and factory automation applications often use these shaft sizes. Ruland disc and bellows couplings accommodate all forms of misalignment, are zero-backlash, and have a balanced design for reduced vibration at speeds up to 10,000 rpm.

Learn more.

Simplify your designs with slewing ring bearings

According to Kaydon Bearings, "A slewing ring bearing has rolling elements designed to create a reactive moment within the bearing's dimensions envelope to oppose applied (overturning) moment load," so you can use one bearing instead of two, reducing the height requirements, and even improve performance. Slewing ring bearings can also simplify a drive system by utilizing gear teeth on the inner or outer race. Learn all about slewing ring bearings in this informative article.

According to Kaydon Bearings, "A slewing ring bearing has rolling elements designed to create a reactive moment within the bearing's dimensions envelope to oppose applied (overturning) moment load," so you can use one bearing instead of two, reducing the height requirements, and even improve performance. Slewing ring bearings can also simplify a drive system by utilizing gear teeth on the inner or outer race. Learn all about slewing ring bearings in this informative article.

Read the Kaydon whitepaper.

Jet valve for ultra-small dispensing

DELO's DELO-DOT PN5 LV pneumatic jet valve is designed for micro-dispensing low-viscosity adhesives and other media in miniaturized applications. Thanks to its compact design, it also requires very little space to install in production systems. Interchangeable nozzles with different diameters and a flexible, adjustable plunger stroke ensure precise and reliable applications at different droplet sizes. Volumes of as low as 1 nl can be achieved, which corresponds to droplet diameters of 250 µm or less.

DELO's DELO-DOT PN5 LV pneumatic jet valve is designed for micro-dispensing low-viscosity adhesives and other media in miniaturized applications. Thanks to its compact design, it also requires very little space to install in production systems. Interchangeable nozzles with different diameters and a flexible, adjustable plunger stroke ensure precise and reliable applications at different droplet sizes. Volumes of as low as 1 nl can be achieved, which corresponds to droplet diameters of 250 µm or less.

Learn more.

Stainless steel constant-torque flush-mount hinge

Southco has introduced a flush-mount version of its popular and durable E6 constant-torque hinge. Its low-profile, corrosion-resistant package makes it an ideal solution for maximizing security, longevity, and aesthetics. It offers high torque for demanding applications while maintaining its low profile. Lots of uses.

Southco has introduced a flush-mount version of its popular and durable E6 constant-torque hinge. Its low-profile, corrosion-resistant package makes it an ideal solution for maximizing security, longevity, and aesthetics. It offers high torque for demanding applications while maintaining its low profile. Lots of uses.

Learn more.

Claw vacuum pump for industrial applications

Vacuum expert Leybold has added a new model to its proven CLAWVAC dry claw vacuum pump series: the CLAWVAC CP B. This innovative, rough vacuum pump, designed for robust processes including food processing, material handling, and environmental industries, is powerful, energy efficient, and easy to clean. The intuitive handling of this unit is mainly due to its functional design, which features a pair of claws that rotate in the cylinder with no contact or wear. Its separate gearbox prevents oil contamination. The design ensures short downtimes and long service intervals: 20,000 hr between oil changes and up to 48,000 hr between general overhauls.

Vacuum expert Leybold has added a new model to its proven CLAWVAC dry claw vacuum pump series: the CLAWVAC CP B. This innovative, rough vacuum pump, designed for robust processes including food processing, material handling, and environmental industries, is powerful, energy efficient, and easy to clean. The intuitive handling of this unit is mainly due to its functional design, which features a pair of claws that rotate in the cylinder with no contact or wear. Its separate gearbox prevents oil contamination. The design ensures short downtimes and long service intervals: 20,000 hr between oil changes and up to 48,000 hr between general overhauls.

Learn more.

DualVee linear guides and tracks used in warehousing

See how Bishop-Wisecarver's DualVee® motion tech can add huge benefits to warehousing operations. This video highlights two applications: a manual storage and retrieval system and an automated storage and retrieval system of long aerospace-grade carbon fiber in sub-zero temps. Patented DualVee guides and tracks keep operations running smoothly.

See how Bishop-Wisecarver's DualVee® motion tech can add huge benefits to warehousing operations. This video highlights two applications: a manual storage and retrieval system and an automated storage and retrieval system of long aerospace-grade carbon fiber in sub-zero temps. Patented DualVee guides and tracks keep operations running smoothly.

View the video.

Build-to-order knobs and hand hardware

Rogan Corp.'s innovative use of two-shot plastic injection and insert molding has been providing customers with high-quality plastic clamping knobs, levers, and control knobs for almost 90 years. Rogan offers concurrent engineering, product design, and assistance in material selection to ensure customer satisfaction for standard or customized parts, with a focus on cost optimization and on-time delivery. Custom colors, markings, decorative inlays, or engineered materials to meet special requirements, such as adding extra strength or utilizing flame-retardant material, are all offered.

Rogan Corp.'s innovative use of two-shot plastic injection and insert molding has been providing customers with high-quality plastic clamping knobs, levers, and control knobs for almost 90 years. Rogan offers concurrent engineering, product design, and assistance in material selection to ensure customer satisfaction for standard or customized parts, with a focus on cost optimization and on-time delivery. Custom colors, markings, decorative inlays, or engineered materials to meet special requirements, such as adding extra strength or utilizing flame-retardant material, are all offered.

Learn more.

Slewing ring bearing made of wood and plastic

The PRT-02-30-WPC slewing ring bearing is another step forward by igus toward integrating renewable raw materials into industrial production. Made of 50% wood and 50% high-performance plastics, the cost-effective and lubrication-free slewing ring bearing balances strength and durability with a proven low CO2 footprint. The materials incorporate solid lubricants, making the new slewing ring bearing smooth running and maintenance-free.

The PRT-02-30-WPC slewing ring bearing is another step forward by igus toward integrating renewable raw materials into industrial production. Made of 50% wood and 50% high-performance plastics, the cost-effective and lubrication-free slewing ring bearing balances strength and durability with a proven low CO2 footprint. The materials incorporate solid lubricants, making the new slewing ring bearing smooth running and maintenance-free.

Learn more.

Flex Locators for quick fixture changeover

Flex Locators from Fixtureworks are designed for quick changeover of small and large fixtures, automation components, and more. They are ideal for applications that require frequent disassembly, providing excellent repeatability for locating and clamping in a single operation. Manual and pneumatic versions are available. Just turn the handle, knob, or screw!

Flex Locators from Fixtureworks are designed for quick changeover of small and large fixtures, automation components, and more. They are ideal for applications that require frequent disassembly, providing excellent repeatability for locating and clamping in a single operation. Manual and pneumatic versions are available. Just turn the handle, knob, or screw!

View the video.

Engineers develop ballistic wallpaper, pop-up guard towers, laser guns for military

By David Vergun, U.S. Army

Nick Boone, a research mechanical engineer with the U.S. Army Corps of Engineers' Engineer Research and Development Center, in Vicksburg, MS, shows a section of ballistic wallpaper during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

Troops often use abandoned masonry, brick, or cinderblock structures for defensive purposes instead of building their own or digging foxholes.

While these structures offer a degree of protection, they are susceptible to blast impact from missile or other large projectiles, said Nick Boone, a research mechanical engineer with the U.S. Army Corps of Engineers' Engineer Research and Development Center, or ERDC, in Vicksburg, MS.

Boone spoke during DOD Lab Day at the Pentagon May 14, where a large number of Army laboratory exhibits were on display.

Engineers at ERDC came up with a novel idea of fortifying these structures with rolls of lightweight ballistic wallpaper with adhesive backing that can quickly be put up on the inside of the walls, he said.

The wallpaper consists of Kevlar fiber threads embedded in flexible polymer film, he said.

Without the wallpaper, a wall that is hit will "rubblize," he said, sending shards of rock and mortar flying at the occupants inside.

When the blast occurs with the wallpaper installed, it acts as a "catcher's net," containing the rubble and preventing debris from injuring Soldiers.

Engineers built unreinforced structures and actually bombed and blasted them, Boone said, showing a video of the experiments. Small blast testing was done at nearby Fort Polk, LA, and large-blast testing was conducted at Eglin Air Force Base, FL.

Ballistic wallpaper is still in the research and development stage and does not yet have an official name, but it could one day be produced and fielded and hopefully save lives, Boone said.

Other protection

Improved protection mortar pits and guard towers, designed by engineers at ERDC and royal engineers from the United Kingdom, have recently been shipped to Afghanistan, Boone said.

ERDC engineers developed the Modular Protective System, or MPS. These are inexpensive, lightweight, easily assembled and disassembled panels attached by cross-braces, which offer "a lot of protection," he said. The panels were developed by ERDC, and the cross-braces were developed with collaboration from the royal engineers.

"We got the idea from picnic chairs that fold up neatly," he said.

The structures are pretty basic, he said. The braces are made of lightweight galvanized steel tubing, and the panels are made of multi-layered fiberglass.

Modular Protective System models of guard towers and mortar pit protection are shown during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

Boone showed models of the fortification as well as full-size versions. They resembled scaffolding. The steel tubing is crossed-braced at angles that afford the greatest strength, he said. It is strong enough to protect against military-grade rounds.

Besides being inexpensive, strong, and lightweight, the MPS can be quickly assembled by just a few Soldiers without any specialized tools or equipment, he said.

Another positive is that the entire MPS structure fits inside a small container that can be sling-loaded under a CH-47 Chinook helicopter for rapid delivery, he said. The beauty of it is that the shipping container itself then becomes the ammunition storage for the mortar pit structure. For the guard tower, the shipping container becomes a platform to support it.

Once the mission ends, everything gets packed back into the shipping container. Nothing gets wasted or left behind, he said.

The mortar pit MPS kits are being used by Soldiers of the 82nd Airborne Division in Afghanistan, he said. The guard towers are being used by the royal engineers there as well. A small, expeditionary guard tower for the U.S. Army has not yet been deployed.

MPS is standing by for licensing and for a possible transition to a program of record, he said.

Contaminants protection

While protection from blast is fairly evident, protection from the unseen can be just as deadly.

Dr. Brandon Lafferty, a research soil scientist with ERDC, said that while operating in enemy territory, Soldiers sometimes come across existing infrastructure that poses threats that cannot be seen.

"Sometimes, those buildings were abandoned for a reason," Lafferty said. "They may have been a chemical processing site, a waste dump, we just don't know. There are currently no portable tools to rapidly determine possible hazards."

Soldiers on the move often do not have time to wait for heavy test equipment to be trucked in and tested by specialists, he continued.

ERDC engineers developed the "Environmental Toolkit for Expeditionary Operations" to address this problem, he said.

Dr. Brandon Lafferty shows the Petroleum Environmental Test Kit during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

An engineer, who is not a specialist, can toss all the instruments he needs in his rucksack and determine if contaminants are present and what their levels of concentration are, he said, so that a commander can make an informed decision whether or not to occupy the structures or area.

The three pieces of gear used for testing include the Hand-held Fluorescent Spectrometer, which measures heavy metals in soil and water; the Petroleum Environmental Test Kit, which identifies and measures petroleum content in soil and water; and the Water Dog, which tests water properties for hardness, acidity, conductivity, and turbidity to determine if the water is contaminated, good for drinking, or maybe just clean enough for washing clothing.

When Soldiers decamp, the area is tested once more because of environmental reporting that requires an area to be left uncontaminated, he said.

Soldiers are being trained to use the test equipment at the Maneuver Support Center of Excellence on Fort Leonard Wood, MO. Test equipment is now being field tested in Kuwait and Iraq, he said.

Video teleconference in a suitcase

When Soldiers need to set up an outpost or bivouac in an unfamiliar area, there might be hazards nearby like landslides or flooding that they're not aware of.

To determine if the location is safe, Soldiers can contact the experts at ERDC who have all of that information readily available, said Vernon Lowery, general engineer, ERDC.

To make contact in remote areas possible, ERDC has supplied the entire Army with Telecommunications Equipment Deployable, or TCED. This video teleconferencing capability comes in a small suitcase that is easily carried by one person, he said. The communications equipment links to Vicksburg via satellite.

Soldiers in remote areas might also want to communicate with people other than at ERDC for various reasons. Lowery said ERDC can relay them to Video Teleconferences, or VTCs, elsewhere around the world.

Vernon Lowery, general engineer, ERDC, shows the telecommunications equipment deployable during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

For example, when Soldiers deployed to Haiti to assist with earthquake humanitarian assistance relief in 2010, they used TCED to establish command and control. Lowery said Soldiers told him it was their "lifeline," and without it, they could not have accomplished their mission.

Laser protection

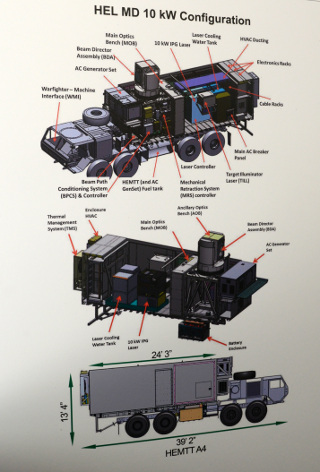

Laser guns may sound like the stuff of science fiction, but engineers at the U.S. Army Space and Missile Defense Command - Technical Center at Redstone Arsenal, AL, have successfully developed and tested just such a system, known as High Energy Laser Mobile Demonstrator, or HEL MD.

Dee Formby, an engineer involved in its development, said that a 10-kW laser, mounted on a Heavy Expanded Mobility Tactical Truck A4 platform, successfully took out 60-mm mortars and unmanned aerial vehicles at White Sands Missile Range, NM, last year.

Workings of the High Energy Laser Mobile Demonstrator are shown during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

Once the laser locks on, it essentially fries its target, Formby said. It is a cost-effective way to destroy cruise missiles, unmanned aerial vehicles, mortars, rockets, and artillery.

A 60-mm mortar round fried open by a High Energy Laser Mobile Demonstrator during testing is shown during DOD Lab Day at the Pentagon May 14, 2015. [Photo Credit: David Vergun]

In good weather, the laser achieves a high success rate, he said. Right now, the system does not perform as well in degraded weather and atmospheric conditions. Distance-to-target remains classified.

In 2017, a 50-kW version will be tested, followed by a 100-kW demonstration in 2020. Higher power means quicker kill time of the projectile, he said, because more power is on the target.

Published 2015

Rate this article

View our terms of use and privacy policy