|

| August 16, 2016 | Volume 12 Issue 31 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

That's how it is: Six surprising capabilities of modern hydraulics

By Dr. Steffen Haack, Bosch Rexroth

Anyone gaining only a superfluous familiarity with fluid technology will easily underestimate the performance and intelligence of modern hydraulics. Who would think that this technology is highly precise, energy efficient, and ready today for Industry 4.0 applications? Here are six capabilities of this strong drive technology that probably come as a surprise for many:

A benefit of hydraulics is that the power generation is decentralized, so high forces can be generated using minimal space.

1. Micrometer precision: Electrohydraulic axis controllers close the control loop decentrally, similar to electrical servo drives, and harmonize the target/actual position in real time within milliseconds. The precision of the movement solely depends on the respective utilized measuring system. In tool and plastic machines, hydraulic drives reliably position axes to a few micrometers of precision.

2. Compact: It is often difficult to place electromechanical drives with sufficient performance in tight construction spaces. Unlike hydraulic drives, they also add significant heat. Since power generation is decentralized in the power unit and since it is connected to the actuator via lines or pipes, OEMs can generate high forces even on minimal construction space. The relatively low level of heat created in the work area dissipates optimally through the hydraulic fluid.

The Bosch Rexroth Sytronix system uses decentralized intelligence in the electronic control device to adjust the rotational speed of the hydraulic pump drive on demand as needed to achieve energy savings.

3. Need-based energy efficiency: Software combines the best from electrical and hydraulic systems. The decentralized intelligence in the electronic control device adjusts the rotational speed of the pump drive on demand as the consumer requires power or it lowers it to zero. In comparison to common constant drives, this reduces the energy consumption of hydraulic power units by up to 80 percent. By the way, even older facilities and machines can be retrofitted without major efforts to significantly reduce the energy consumption in production.

4. Balanced drive physics: Fluid technology is not always inherently linear. Drive software for hydraulic actuators takes these particularities into consideration and harmonizes them automatically. Pre-programmed, typical hydraulic functions (e.g., synchronization or position-dependent braking) merely require the optimization of parameters within the scope of startup. They are based on a transparent software structure and function equally on all hardware platforms.

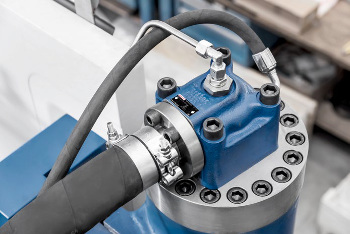

Ready-to-install servo-hydraulic axes, such as the one used on this axial press, have an integrated fluid loop and are driven by the same servo drives as the electromechanical versions.

5. Open and outgoing: With increasing frequency, real-time Ethernet protocols in modern machines integrate all actuators and peripherals into each other. Modern motion controls for hydraulic drives support all common protocols (e.g., Sercos, EtherCAT, Ethernet IP, PROFINET RT, Powerlink, and Varan). Their software is also based on open standards (e.g., IEC 61131-3 and PLCopen). With this, they are an ideal match for the increasingly integrated and technology-overlapping infrastructure of modern production environments -- all the way up to Industry 4.0.

6. Simply exchangeable: Ready-to-install servo-hydraulic axes have an integrated fluid loop and are driven by the same servo drives as the electromechanical versions. Since axes are encapsulated systems, engineers must only connect power and communication cables for assembly and startup, and startup can begin. Everything else, for example the parameterization values determined from simulations, is already stored in the drive software and supports the plug-and-run philosophy.

About the author

About the author

Dr. Steffen Haack is a member of the executive board responsible for the Business Unit Industrial Applications and Coordination Sales, Bosch Rexroth AG.

Learn more at https://www.boschrexroth.com/en/xc/products/product-groups/industrial-hydraulics/index

Published August 2016

Rate this article

View our terms of use and privacy policy