|

| March 27, 2018 | Volume 14 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

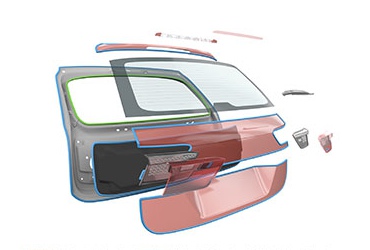

Dow structural adhesive joining solutions enhance lightweight module construction in automotive

Dow Automotive Systems is leveraging its existing structural adhesives portfolio as well as its development expertise to offer BETAFORCE, BETAMATE, and BETASEAL solutions that enhance lightweight module construction. Liftgate/hatchback, decklids, and front-end carrier modules are increasingly designed using a multi-material mix to decrease weight while maintaining design flexibility, styling, and safety performance. Structural bonding of these lightweight modules delivers on these customer needs.

"For those Tiers and OEMs adopting mixed-material design, 3-kg to 10-kg weight savings per module have already been realized," said Christophe Van Herreweghe, marketing manager, Body & Exteriors, Dow Automotive Systems. "Use of Dow structural adhesives helps enable those targets and further enhances the module through the ability to bond dissimilar substrates, reduce welding and mechanical fasteners, seal against corrosion for better durability, and increase strength and stiffness for crash worthiness and enhanced customer driving experience."

Dow structural adhesives are developed with rapid-cure characteristics that process well in mass production manufacturing environments. Primerless-to-plastic formulations help remove VOCs from assembly operations, and new multifunctional adhesives are in development.

Structural bonding of modular assemblies has a success record of over 20 years. Creating new formulations that align with advances in materials technology and sustainability targets primary industry commitments for Dow. Dow products are on current platforms including the Jeep Cherokee liftgate (through collaboration with Magna) and will be launched on other 2019 series later this year.

BETAFORCE

For high-performance bonding in lightweight multi-material vehicles, BETAFORCE composite bonding adhesives enable significant weight reduction, improved acoustic performance, and enhanced corrosion protection. Design flexibility is maintained while processing performance and sustainability goals are achieved. BETAFORCE joins carbon fiber and glass fiber composites, as well as other dissimilar materials, in a variety of lightweight designs and modular assemblies. This product can be used to bond coated metals such as steel to aluminum, carbon fiber panels to steel or aluminum, sheet molding compound (SMC) to aluminum, and more. The latest formulations of BETAFORCE offer a cycle time of approximately one minute and are currently being used for mass series production. Open times can be adjusted as needed.

BETAMATE

BETAMATE structural adhesives deliver cutting-edge solutions in similar and dissimilar material bonding, closure bonding, and body structure bonding, enabling improved load-carrying capabilities, vehicle stiffness and durability, design flexibility, and weight reduction. These structural adhesives offer high-performance adhesion to automotive substrates such steel, aluminum, magnesium, and composites, innovatively replacing welds and mechanical fasteners, reducing fatigue and failure commonly encountered with traditional processes, and substantially increasing manufacturing efficiencies.

BETASEAL glass bonding for automotive

BETASEAL glass bonding systems are used worldwide for the structural bonding and sealing of stationary vehicle glass. These glass bonding systems consist of BETACLEAN cleaners, BETAPRIME primers, and BETASEAL adhesives to provide a total bonding solution for glass bonding applications.

Source: Dow Automotive Systems

Published March 2018

Rate this article

View our terms of use and privacy policy