|

| March 26, 2019 | Volume 15 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New treatment helps in cutting advanced metals

The process adds to a growing list of often-simple topicals that can improve metal cutting for defense, vehicles, health products, and more.

Most people may not realize it, but they encounter products made with exotic or advanced metals every day.

The metals are used in aircraft, orthopedic components, medical instruments, cars, solar panels, military equipment, and other applications, and are called advanced or exotic because they are more difficult to find and more costly to use in manufacturing.

But the conventional method of using advanced metals in manufacturing is high in cost, in part because they tend to be difficult to sculpture. Now, a new process for cutting these metals may help make them easier to use and lead to significant changes in the future of manufacturing. It's a growing industry; the global metal fabrication market value is expected to reach $24 billion by 2024.

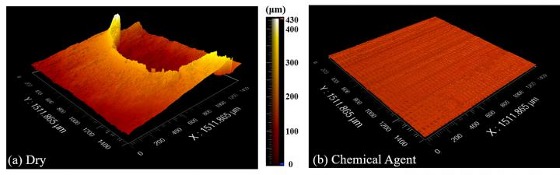

A team from Purdue University discovered that the application of surface-active chemical agents enables metal cutting to be significantly improved with reduced forces and better surface quality. [Credit: Srinivasan Chandrasekar/Purdue University]

"What we have created is a new way to approach the machining of these metals that has the potential to change manufacturing system processes," said Srinivasan Chandrasekar, a professor of industrial engineering in Purdue University's College of Engineering. "Our solution is showing great promise in making these metals more affordable to manufacture and process by making them easier to machine."

The Purdue team created a method for applying a designer surface-active agent -- the name for a variety of chemicals used in metals processing -- to the surface of a metal to make it easier to cut and shape the material into parts and pieces. The research is published in the Jan. 10 issue of Physical Review Applied.

Researchers at Purdue used common alcohols on an aluminum surface and were able to cut the metal more easily, with at least 50 percent less force, and produce a smoother end surface with fewer cracks and tears compared with aluminum without the alcohol treatment.

"Purdue provides an extraordinary environment to conduct this kind of research that you will not find at most other universities," Chandrasekar said. "We have lab equipment and space to test our methods at the scale found in actual manufacturing industry facilities and spaces."

Chandrasekar said the same approach is showing promise for other metal systems such as stainless steel, tantalum, copper, iron, and even nickel alloys. Each metal system requires a specific designer agent, since alcohols do not interact with other metals in the same way as they do with aluminum.

Chandrasekar and his team have worked with the Purdue Research Foundation Office of Technology Commercialization on patenting their technologies. They are looking for additional research partners.

Previous research by the same team demonstrated the application of metal marking inks and glues to make gummy metals such as aluminum, stainless steels, copper, and tantalum much easier to cut for industrial applications. [See "Is your metal too 'gummy' to cut? Draw on it with a Sharpie or glue stick" (Designfax, Aug. 14, 2018)]

Their work aligns with Purdue's Giant Leaps celebration, acknowledging the global advancements in sustainability as part of Purdue's 150th anniversary. This is one of the four themes of the year-long celebration's Ideas Festival, designed to showcase Purdue as an intellectual center solving real-world issues.

Source: Purdue University

Published March 2019

Rate this article

View our terms of use and privacy policy