Super-charged battery cells help break world speed record

The KillaCycle Team uses A123’s M1 cells to make it into history books

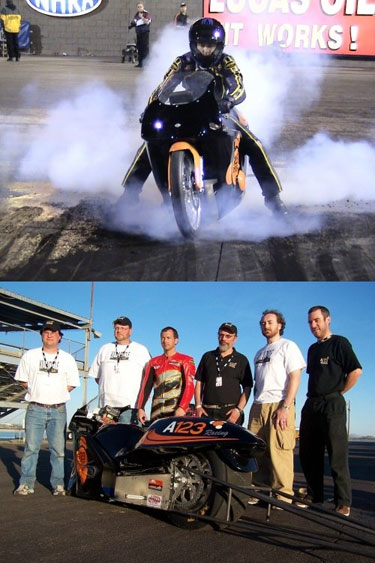

By removing traditional technological constraints, A123’s nanophosphate technology helped the KillaCycle Team optimize their battery cell package to aid in breaking the quarter-mile electric vehicle drag world record. A battery pack consisting of M1 cells helped the KillaCycle accelerate from 0 mph to 60 mph in less than 1.5 sec.

What powers the world’s fastest electric motorcycle? After recently breaking the quarter-mile drag world record for an electric vehicle (EV) at the All Harley Drag Racing Association (AHDRA) meet in Chandler, AZ, at the Firebird Speedway, the KillaCycle Team attributes a major portion of their success to A123 Systems’ nanophosphate technology in the lithium-ion battery cells used to power the bike. The new time wiped out the long-standing top EV record (held by a traditional dragster) that lasted for more than six years.

“We call the A123 Systems battery pack ‘Mister Fusion’ because it acts like a bottomless pit of power and energy on the track,” says Bill Dubè, designer, builder, and owner of the KillaCycle.

Using a custom-made battery pack of M1 cells to power the KillaCycle, Dubè and his team easily broke the previous quarter-mile electric vehicle record, finishing the run at 8.168 sec at a speed of 155.78 mph (more than 0.6 sec faster than the previous record). During the time trials, KillaCycle’s power output topped out over 350 hp, and the team was able to draw 1,575 A from the 375-V, 7.5-kWh M1 battery pack. At a weight of just over 160 lb, the light, durable, and high-powered M1 cells certainly had a hand in the KillaCycle Team’s record-breaking feat.

“We could make seven or eight runs without recharging if we wanted,” Dubè says. “It only takes a few minutes to recharge the pack between runs, so we top it off every time. We only use about 700 Wh (about $0.10) of electricity for each round. This includes the burn-out and the more than two-mile round trip back to the pits!

“We built a new battery pack with 990 A123 M1 Li-Ion cells. We also implemented a contactor system that allows the bike to shift the motors from series connection on the launch, to parallel connection further down the track. This allows us to push 2,000 A through both motors on the starting line to get something close to a total of 800 ft-lbs of torque. This results in about 2,000 ft-lbs of torque on the back tire.”

Perhaps the most impressive trait of A123’s M1 cells is their ability to produce over 3,000 W of power per kg (5,800 W per liter), while still offering an environmentally friendly, inherently safe alternative to regular battery cells. The M1 lithium-ion batteries use a new type of cell construction based on a dual-plate tubular design optimized to deliver maximum power with high efficiency. The advanced all-laser-welded construction optimizes for very low humidity penetration over the life of the battery, and uses strong, thick, dual-plated headers.

A123 Systems’ M1 nanophosphate design uses patent-pending laser-welded multi-plate tubular construction that is vibration and abuse tolerant. This process offers durable hermetic sealing with the lowest internal resistance. While most conventional cells experience a growth in their internal resistance as they are cycled at high rates/temperatures, M1 cells are uniquely engineered so their internal resistance (impedance) actually decreases with use.

In addition to the nanophosphate technology imbuing the M1 cells with four times higher thermal conductivity than regular Li-ion cells, A123 cells may be the most efficient temperature-managing cylindrical cells on the market, and they require none of the cooling systems that plague applications using traditional products.

Due to the faster kinetics of A123’s M1 nanophosphate technology, the company is able to manufacture battery cell electrodes with lower ASI (area specific impedance). As a result, more energy can be extracted from these electrodes to deliver previously unattainable levels of power, safety, and battery life.

A123’s proprietary nanophosphate materials produce extreme levels of power without sacrificing improved safety, due to their unique chemistry. The nanophosphate cathode used in Li-ion cell production eliminates a dangerous cause of battery failures: oxygen release and the resulting thermal runaway. Initiated by an overcharged metal-oxide cathode, thermal runaway is a common cause of fires/explosions and remains a serious concern when using conventional Li-ion batteries. In contrast to NiCd and other Li-ion technologies, M1 cells do not employ heavy metals and elements known to be highly toxic or potentially carcinogenic.

Nanophosphate cells also have the unique ability to charge to high capacity in 5 min or less. A significant improvement over conventional Li-ion (the average recharge typically requires 90 min or more), the fast-charge capability lends a new level of convenience for users of cordless products and practical electric drive/propulsion vehicles. M1 nanophosphate cells can also aid applications in laser designation systems, transmission power sources for micro sensors, non-lethal electric weapons, aerospace/ground engine start systems, distributed jamming systems, and a many more.

Want more information? Click below.

A123 Systems

Want more information? Click below.

KillaCycle

© Nelson Publishing, Inc. All Rights Reserved