Software News

DSM Somos introduces innovative software to produce reduced-density, structural stereolithography parts

DSM Somos recently announced that it will introduce a new software application allowing Stereolithography (SL) users to create lightweight prototypes having enhanced structural integrity.

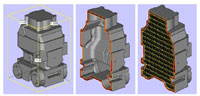

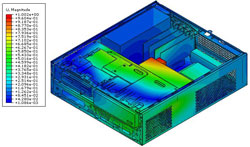

Based on patented technology from the Milwaukee School of Engineering (MSOE), TetraShell hollow-build software will use MSOE’s TetraLattice technology to facilitate the manufacture of hollow stereolithography parts with variable skin thicknesses, supported by a patented and proprietary TetraLattice support structure. Potential application areas include investment casting patterns; reduced-density metal-clad composite structures; and lightweight large, thick-sectioned parts.

Cross-sectional view of an enclosed shape that is hollowed, then reinforced by a TetraLattice network using DSM Somos TetraShell software for stereolithography parts production.

“Until now, hollow-build SL software has been restricted primarily to investment casting pattern applications,” says DSM Somos product development manager Brian Bauman. “The TetraShell software will allow SL part builders to widely vary wall thickness, as well as to adjust support parameters — and consequently opens doors previously closed to SL because of cost or weight considerations. Due to overall reduction of mass, the TetraShell hollow-build style will create considerable material savings for customers with bulky parts, while at the same time increasing part accuracy.”

The TetraShell software is a proprietary DSM Somos application module supported by Materialise’s Magics software and can easily be used on all current SL equipment. Beta testing is now underway, with widespread availability of the software in conjunction with Somos resins expected by year end.

Want more information? Click below.

DSM Somos

Software Products

CAM Express Version 6 is full NCC control

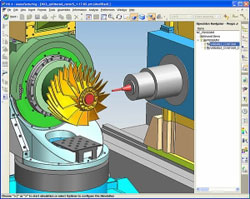

CAM Express software is the full-function numerical control programming software component of the Velocity Series portfolio. It covers a wide variety of programming requirements from high-speed machining to multi-function mill-turning to 5-axis machining.

CAM Express 6 includes new capabilities across the critical 3-axis machining application space, including specific high-speed machining approaches, to enable: simplified tricky tracing cuts with new cutting strategies for curve/edge and 3D profile cutting, 10% faster roughing cuts with the latest optimized corner rounding techniques, smoother finish cuts, and more effective toolpaths. The software also includes four more tutorials that help new users get going quickly.

Want more information? Click below.

Siemens PLM Software

Mark out your new lean manufacturing space

MARKWARE LEAN TOOLS software provides a template wizard with hundreds of pre-formatted templates for safety signs, equipment ID, hazardous communication labels, inspection tags, and more. The software helps post critical information at the point of use when implementing 5S, Total Productive Maintenance, Standard Work, Kanban, or other lean concepts. Users can create a variety of visual equipment controls, including gauge labels, oil level indicators, and drive tension guides to support and sustain a lean transformation.

These controls help achieve faster machine setups and changeovers, detect operating abnormalities at a glance and at a distance, simplify training of operators and other non-technical staff responsible for routine machine inspection and care, and enable more efficient route-based monitoring of numerous PM points in condition-based maintenance programs.

Want more information? Click below.

Brady Corporation

CAD/CAM gets easier to learn

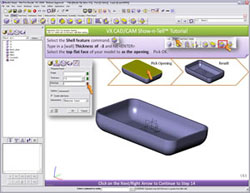

VX Corporation, specializing in CAD/CAM for consumer products, molds, and machining, announced the release of its new Show-n-Tell communication tool at IMTS 2008. Show-n-Tell is built into VX CAD/CAM for on-screen step-by-step lessons and to automate design review and markup as a 3D Markup tool.

The Show-n-Tell tutorial is launched by loading a VX file. Users can step back and forth with a click of a button, and all instructions are on screen — eliminating the need to flip back to a video or hold a book open. 3D models, showing the expected result, can be rotated and zoomed, giving the user better feedback and understanding. Users work at their own pace, not that of an instructor, so no one gets left behind. VX allows the user to save the Show-n-Tell tutorial session and reload it at a later date. Future tutorials will cover parametric and open shape modeling, sketching, assembly, drafting, 2X and 3XCAM, automated hole drilling, importing and healing, part splitting, electrodes, direct editing, morphing, surfacing, and reverse engineering.

Want more information? Click below.

VX Corporation

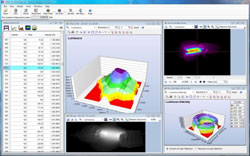

High-accuracy laser beam profiling software

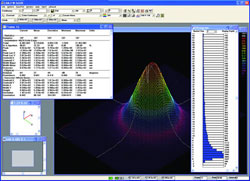

Designed for a variety of scientific R&D and manufacturing applications, LBA high-accuracy laser beam analysis software contains all the algorithms and calculations necessary to make the most accurate beam measurements, including quantitative calculations, 2D and 3D viewing, user-defined apertures, multiple frames averaging and summing, zoom up to 32 times the original size, and user-selectable Z-axis (intensity) scaling.

LBA measurement precision is based on Ultracal, the company's patented, baseline correction algorithm that helped establish the ISO 11146-3 standard for beam measurement accuracy. Ultracal aims to ensure the highest accuracy and reliability in the industry by retaining negative signals essential for making correct beam width measurements and for extracting weak signals out of noise.

Want more information? Click below.

Ophir-Spiricon

Light source modeling brightened

ProSource 8.0 is the newest version of Radiant Imaging’s software for light source near-field data analysis and ray generation. ProSource 8.0 provides simpler, more intuitive program navigation, enhanced graphics, and improved ray generation from Radiant Source Model data files. The software is intended for use by light source and lighting system designers and developers, and applies to all light sources including emerging LED applications.

“ProSource and Radiant Source Models are already well established as the most accurate way of representing real light sources for optical design purposes,” says Hubert Kostal, Radiant Imaging vice president of Sales and Marketing. “ProSource 8.0 adds significant analysis functionality and is easier to use. Users will realize both improved efficiency and increased accuracy in optical design applications.”

Want more information? Click below.

Radiant Imaging

FEA modeling gets an extreme makeover

ALGOR V22 software significantly upgrades all areas of FEA: modeling, simulation, and results evaluation and presentation, providing users with increased power, flexibility, and ease of use for simulating engineering analyses of their product designs.

New and improved features include: expanded support for 64-bit systems, open channel flow, a multifrontal massively parallel solver (MUMPS), damage analysis, remote loads, improved beam modeling, meshing improvements, mesh studies, enhanced tools for pressure vessel design, and the capability to display flow rate results.

Want more information? Click below.

ALGOR

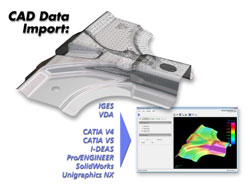

Sheet metal forming simplified

AutoForm has enhanced its EasyBlank software by creating an add-on module that enables the direct import of various native CAD files, avoiding the need to convert different CAD data into standard formats. Within the EasyBlank software, the user now imports not only IGES and VDA files but also the native files generated by CATIA V4, CATIA V5, Pro/ENGINEER, I-DEAS, SolidWorks, and Unigraphics NX.

EasyBlank is free downloadable software that enables online purchasing of reports. EasyBlank rapidly calculates the developed blank outline from CAD part geometry, using the well-known AutoForm-OneStep technology. In addition, EasyBlank is specialized for determining the optimal nesting layout. All the existing features make the software attractive for tool and die shops as well as for stamping companies. The license for the add-on module can be purchased online. Users can experience the new functionality first hand by obtaining a free-of-charge, one-week trial version.

Want more information? Click below.

AutoForm Engineering

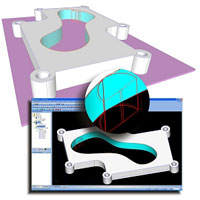

2- and 4-axis wire EDM CAD/CAM software for manufacturing precision parts

Version 22 of the BobWIRE system provides an intuitive interface that gives the operator improved control over managing the program from start to finish. As a complete solids and surface CAD system with an expanded list of import file types, the operator can use outside CAD systems or design the part in-house. The built-in toolpath associativity between the part geometry and the wire machining features in the CAM tree manager make on-the-fly geometry edits or modifying cutting variables simple.

New features include automatic Open and Closed Shape machining, operator definable cutting conditions for different machines, as well as being able to specifically assign cutting conditions to part files for future use. Other features include multiple wire approach types, land and taper options for 2-axis part making, as well as match point features that give operators complete control when programming complex 4-axis parts.

Want more information? Click below.

BobCAD-CAM

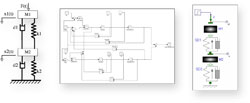

MapleSim is new physical modeling “landmark” from Maplesoft

Physical modeling, or physics-based modeling, is the process of modeling the dynamic behavior of a system mathematically. Traditionally, this task required significant manual effort to derive equations and manipulate them into a form that could be used by signal-flow simulation tools that employ a block-diagram paradigm. The block diagrams are more complex, harder to produce, and do not resemble the original system representation.

With the cutting-edge physical modeling techniques in MapleSim, users can re-create a system diagram on a screen using compact and intuitive components that represent a physical model, making it easier to build and understand. MapleSim has more than 500 components from over 10 domains such as electrical, mechanical, control design, and thermal, organized into easy-to-navigate palettes.

Want more information? Click below.

Maplesoft

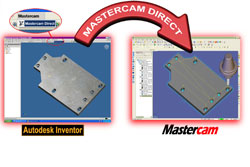

Mastercam X2 now certified for Autodesk Inventor 2009

Mastercam X2 CAD/CAM Software has been certified for Autodesk Inventor 2009 software by the Autodesk Inventor Certified Applications Program. To be certified, the product must meet certain guidelines and demonstrate a high level of quality as well as compatibility with Autodesk Inventor. Certification is given only after the product has been tested and approved.

Mastercam X2 has a direct add-in for Autodesk Inventor, a new way to boost productivity. Free to the Mastercam and Autodesk communities, Mastercam Direct enables users to open a model in Mastercam while in an Inventor session, and then update toolpaths to reflect changes to the model. Mastercam X2 is able to read in native Inventor files for design purposes and toolpath generation.

Want more information? Click below.

CNC Software

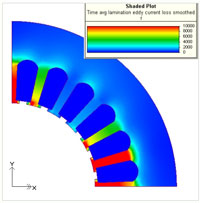

Calculations for coupled electromagnetic and thermal simulations

The newest releases of MagNet and ThermNet are now available. ThermNet now supports coupling with Magnet’s new core loss calculation method that computes the hysteresis plus the anomalous and eddy current losses in both 2D and 3D. In a simulation, the advanced core loss calculation algorithm for eddy currents takes different harmonics into account and, for hysteresis loss, it takes into account the minor loops.

ThermNet and MagNet are now available for PCs running Microsoft Windows 2000, XP, and Vista.

Want more information? Click below.

Infolytica Corporation

Industrial-strength fluid flow and heat transfer sim

In this latest major software release, CFdesign v10 focuses on further shortening the learning curve for first-timers while adding industrial-strength problem-solving capabilities, including cavitating flow prediction and thermo-electric cooler analysis, to the engineering desktop.

“We focused on the total user experience from a first-timer’s perspective,” says Blue Ridge president Ed Williams. “CFdesign v10 is about democratizing fluid flow and heat transfer simulation. An engineer with limited or no previous engineering analysis experience can achieve extensive flow and thermal design studies in a fraction of the time it would take most CFD experts. By knocking down the intimidation-factor, we believe v10 makes it easier for companies to move CFD further upstream in the design process.”

Want more information? Click below.

Blue Ridge Numerics

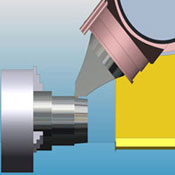

Improved automation of NC programming

Planit has announced the release of Edgecam 12.5. This latest release delivers extensive new capabilities to many areas of the product, including ease of use, automation, mill-turn programming, and integration with solid CAD systems.

A new rough turning cycle includes improved chip control, reducing notching and tool wear. Also within the turning environment, enhanced chuck jaw and chuck setup options contribute to greater machine tool set-up flexibility and improved collision detection.

Want more information? Click below.

Planit

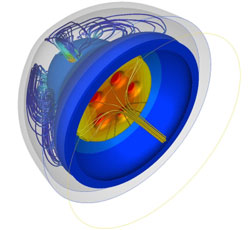

Abaqus 6.8 accelerates realistic simulation

Dassault Systèmes announces the availability of Abaqus 6.8, its technology-leading unified finite element analysis (FEA) software suite from SIMULIA. Engineers, designers, researchers, and scientists use Abaqus to lower costs and reduce cycle times through the realistic simulation of stress, impact, crush, fluid-structure interaction, thermal dynamics, and other complex behaviors of products, materials, and processes.

With a focus on solving specific engineering challenges in automotive, aerospace, electronics, energy, packaged goods, and other industry segments, Abaqus 6.8 provides new and improved capabilities in core areas, including modeling and results visualization, structural analysis, composites failure, general contact, computing performance, and multiphysics.

Want more information? Click below.

Dassault Systèmes

RedEye RPM and Alibre partner to offer instant rapid prototyping quotes

RedEye RPM, a business unit of Stratasys, and Alibre, Inc. have announced a new partnership that enables users of Alibre Design 3D CAD software to obtain instant quotes for designs using RedEye’s Web-based quoting system.

As part of the partnership, RedEye created a software add-on for Alibre Design that generates instant quotes for parts and assemblies directly inside the Alibre Design interface. In addition, designers can securely transmit the design to RedEye to build after receiving a quote. The quotes are based on services offered by RedEye RPM, which houses nearly 100 additive fabrication systems in its facilities worldwide, most of which are fused deposition modeling systems manufactured by Stratasys.

Want more information? Click below.

Stratasys

Automatic, high-quality meshing tools increase productivity

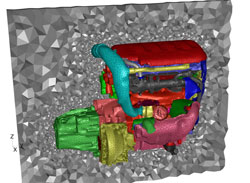

ANSYS has released version 5.0 of its TGrid advanced mesh generation software. TGrid technology is a specialized pre-processor for fluid flow analysis. It is used to create large unstructured tetrahedral and hex-core meshes for complex geometry. The software is utilized heavily in large-scale automotive and aerospace applications, in which advanced meshing techniques are required for the computational analysis of fluid flow.

With this release, a new tetrahedral meshing algorithm, combining the speed of Delaunay and the quality of an advancing front, has been added to the TGrid meshing arsenal. This new technology, in conjunction with an advanced initialization scheme and several quality-enhancing tools, leads to improved accuracy of the fluid flow analysis. In addition, enhanced prism layer operations now include fully automatic proximity handling to support highly complex geometry. Finally, a new cavity re-meshing module allows users to swiftly replace parts and components without re-meshing the full model.

Want more information? Click below.

ANSYS

© Nelson Publishing, Inc. All Rights Reserved