Designfax – Technology for OEM Design Engineers was launched as an exclusive eMagazine in October 2005 following 25 successful years in print. Subscribers to the weekly publication (48 issues a year) are high-level OEM product design engineers and engineering managers who operate in a broad range of manufacturing industries, including automotive, aerospace, appliances, medical equipment, transportation, computer process controls, industrial equipment, and more. Primary content focuses on the latest exciting applications and products for Electrical/Electronic, Mechanical, Motion Control, Fluid Power, and Materials engineering, including articles on powerful software programs that serve as a primary engineering tool. Take a look at what Designfax offers and then subscribe.

| February 10, 2026 | Volume 22 Issue 06 |

|

| Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more. Precision medical molding services available too.

Learn more. Tell Rogan you saw them in Designfax. |

| NASA, Boeing test longer, narrower aircraft wings

The airliner you board in the future could look a lot different from today's, with longer, thinner wings that provide a smoother ride while saving fuel. Those wings would be a revolutionary design for commercial aircraft, but like any breakthrough technology, they come with their own development challenges.

Read the full article. |

| Toyota Land Cruiser 2026: Off-roading with some retro vibes

Since its U.S. debut in 1958, the Land Cruiser has stood as a cornerstone of Toyota's legendary off-road legacy. The heritage-inspired 250 series Land Cruiser for 2026 is a highly capable off-roader -- a mid-size SUV that blends premium features with a more accessible price point than previous generations. Comes in two tasty flavors.

Read the full article. |

| SPIROL Press-N-Lok™ Pin for plastic enclosures

The Press-N-Lok™ Pin from SPIROL has a unique design that enables easy installation, yet incredibly high pull out force, to permanently retain two plastic components to each other. The pin has raised barbs that are angled opposite to the direction of insertion, which allows the pin to provide a secure, tamper-resistant assembly. These pins are manufactured from lightweight, lead-free, and corrosion-resistant aluminum but can also be made from austenitic stainless steel. Now available directly from SPIROL's eCommerce site.

Learn more. |

| One compression spring replaces 24 washers!

Smalley's new Nestawave™ product is a breakthrough in spring design. It combines the space-saving deflection of a Crest-to-Crest® wave spring with the high-force output of a Spirawave® nested spring. In one application, Smalley engineers helped a customer streamline their design by replacing a stack of 24 Belleville washers with a single Nestawave spring!

Read the full article. |

| NEW! Programmable angle sensors

Vert-X 13E sensors from Novotechnik U.S. deliver wear-free, maintenance-free rotary measurement thanks to a touchless magnetic design and hermetic IP69 sealing that shrugs off water, oil, and dust. They provide precise 0 to 360° feedback with 14-bit resolution, SPI/PWM outputs, and 50-year MTTF -- all in a compact 13-mm package that retains absolute position through power loss. Applications include servodrives, insetting machines, robots, and medical.

Learn more. |

| When to use Multi Jet Fusion to make your parts

According to the experts at TriMech Advanced Manufacturing, "Multi Jet Fusion is an industrial 3D-printing technology that fuses powdered materials layer by layer into solid plastic parts. It was developed by HP and was commercialized in 2016." Learn the strengths and limits of MJF and key technology benefits in this thorough overview, which also includes: part optimization, standard materials (Nylon PA12) and specs, applications, and post-processing options.

Read the full TriMech article. A solid primer. |

| Streamline servo linear actuator selection: New Drive Integration Tool

Tolomatic's online Drive Integration Tool simplifies the selection process to seamlessly match a drive system to a servo linear actuator. This tool combines the motor, drive, feedback, and connection info across a wide range of industry-leading manufacturers with Tolomatic's own servo linear actuator specs so you can ensure compatibility and streamline commissioning.

Learn more. |

| Tech Tip: Mastering sheet metal bend calculations in Onshape

Mastering bend calculations in sheet metal design is a key skill that can impact the accuracy and manufacturability of your designs significantly. Explore the various options available to become a pro in this Onshape Tech Tip: K Factor, bend allowance, and bend deduction, with guidance on when each should be used. You will probably learn something even if you don't use this software.

Read the Onshape blog. |

| | Most popular last issue |

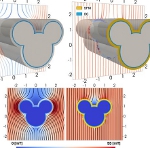

| Scientists engineer unsinkable metal tubes

Can engineers create "unsinkable" ships? Researchers at the University of Rochester have developed a new process that turns ordinary metal tubes unsinkable -- meaning they will stay afloat no matter how long they are forced into water or how heavily they are damaged.

Read the full article. |

|

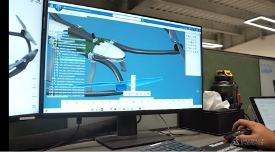

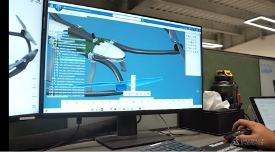

| | Videos+: Technologies and inspiration in action | What goes into designing high-end drones?

See how Raphe mPhibr, a high-end UAV manufacturer in India, uses the 3DEXPERIENCE platform from Dassault Systemes -- which integrates 3D design, analysis, simulation, and intelligence software -- to transform the way aircraft systems are conceived, validated, and built. The company's many innovations include a 600-g 4-kW two-stroke engine that outperforms systems seven times its weight. [Credit: Screenshot courtesy of Dassault Systemes]

See how Raphe mPhibr, a high-end UAV manufacturer in India, uses the 3DEXPERIENCE platform from Dassault Systemes -- which integrates 3D design, analysis, simulation, and intelligence software -- to transform the way aircraft systems are conceived, validated, and built. The company's many innovations include a 600-g 4-kW two-stroke engine that outperforms systems seven times its weight. [Credit: Screenshot courtesy of Dassault Systemes]

View the video. |

|

|

If you choose not to receive any more issues of Designfax, please follow this link

|