|

| June 16, 2020 | Volume 16 Issue 23 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Isolated probing tech for fast-switching power device testing

Keysight Technologies has developed an optically isolated differential probing family dedicated to enhancing efficiency and performance testing of fast-switching devices such as wide-bandgap GaN and SiC semiconductors. Validation of floating half-bridge and full-bridge architectures commonly used in power conversion, motor drives, and inverters requires measurement of small differential signals riding on high common-mode voltages. This measurement can be challenging due to voltage source fluctuations relative to ground, noise interference, and safety concerns.

Keysight Technologies has developed an optically isolated differential probing family dedicated to enhancing efficiency and performance testing of fast-switching devices such as wide-bandgap GaN and SiC semiconductors. Validation of floating half-bridge and full-bridge architectures commonly used in power conversion, motor drives, and inverters requires measurement of small differential signals riding on high common-mode voltages. This measurement can be challenging due to voltage source fluctuations relative to ground, noise interference, and safety concerns.

Learn more.

Protect sensitive electronics in explosive environments with new aluminum ATEX Cabinet Cooler Systems

EXAIR's ATEX Cabinet Cooler® Systems deliver a powerful and affordable solution for keeping electrical enclosures cool in hazardous ATEX classified areas -- and they're now available in durable aluminum construction. Engineered for use in Zones 2 and 22, these coolers are UL tested, CE compliant, and meet stringent ATEX standards for purged and pressurized enclosures. With cooling capacities up to 5,600 Btu/Hr., ATEX Cabinet Coolers are ideal for preventing overheating in electrical cabinets. EXAIR offers a comprehensive lineup of systems.

EXAIR's ATEX Cabinet Cooler® Systems deliver a powerful and affordable solution for keeping electrical enclosures cool in hazardous ATEX classified areas -- and they're now available in durable aluminum construction. Engineered for use in Zones 2 and 22, these coolers are UL tested, CE compliant, and meet stringent ATEX standards for purged and pressurized enclosures. With cooling capacities up to 5,600 Btu/Hr., ATEX Cabinet Coolers are ideal for preventing overheating in electrical cabinets. EXAIR offers a comprehensive lineup of systems.

Learn more.

PLC handbook chock full of must-know information

Automation-Direct's Practical Guide to Program-mable Logic Controllers Handbook has been improved with tons of new need-to-know info, making it a more comprehensive guide to the world of PLCs. Besides covering the basics of PLC history, PLC hardware, and PLC software, this guide takes you deeper into the ever-changing world of PLC communication, the importance of feedback loops, cyber security, and many other areas that are a must-know for any PLC novice or seasoned automation professional.

Automation-Direct's Practical Guide to Program-mable Logic Controllers Handbook has been improved with tons of new need-to-know info, making it a more comprehensive guide to the world of PLCs. Besides covering the basics of PLC history, PLC hardware, and PLC software, this guide takes you deeper into the ever-changing world of PLC communication, the importance of feedback loops, cyber security, and many other areas that are a must-know for any PLC novice or seasoned automation professional.

Get this great resource today.

Haptic feedback prototyping kit from TDK

Get your customers to feel the difference your products make. TDK has released a development starter kit for fast haptics prototyping. It gives mechanical designers and engineers first impressions of the haptic feedback using PowerHap piezo actuators, shows how the mechanical integration works, and provides a reference design. Applications include automotive, displays and tablets, household appliances, vending machines, game controllers, industrial equipment, and medical devices.

Get your customers to feel the difference your products make. TDK has released a development starter kit for fast haptics prototyping. It gives mechanical designers and engineers first impressions of the haptic feedback using PowerHap piezo actuators, shows how the mechanical integration works, and provides a reference design. Applications include automotive, displays and tablets, household appliances, vending machines, game controllers, industrial equipment, and medical devices.

Learn more.

Mini ESD preset torque screwdriver

Need precision fastening with ESD protection at the smallest torque levels? Mountz has you covered. The new FG Mini ESD Preset Torque Screwdriver is built for low-torque, high-precision tasks. Its compact design makes it ideal for tight spaces and small fasteners, while delivering the same reliable control and ESD protection users have come to expect from Mountz. Two models available: FG25z (3 to 25 ozf.in, 2 to 17.7 cN-m) and FG50z (20 to 50 ozf.in, 14.1 to 35.3 cN-m).

Need precision fastening with ESD protection at the smallest torque levels? Mountz has you covered. The new FG Mini ESD Preset Torque Screwdriver is built for low-torque, high-precision tasks. Its compact design makes it ideal for tight spaces and small fasteners, while delivering the same reliable control and ESD protection users have come to expect from Mountz. Two models available: FG25z (3 to 25 ozf.in, 2 to 17.7 cN-m) and FG50z (20 to 50 ozf.in, 14.1 to 35.3 cN-m).

Learn more.

Laumas load cells and electronics from AutomationDirect

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Learn more.

Engineer's Toolbox: What is ground loop feedback?

Improper grounding can create problems in data logging, data acquisition, and measurement and control systems. One of the most common problems is known as ground loop feedback. Experts at CAS DataLoggers run through five ways to eliminate this problem.

Improper grounding can create problems in data logging, data acquisition, and measurement and control systems. One of the most common problems is known as ground loop feedback. Experts at CAS DataLoggers run through five ways to eliminate this problem.

Read the full article.

What is a braking resistor?

According to Automation-Direct, "Braking resistors don't actually provide braking directly -- rather, they allow a drive to stop a loaded motor faster." Why is this important? Protect your AC or DC drive system from regenerative voltage that can create an over-voltage fault on the drive -- especially with high inertial loads or rapid deceleration.

According to Automation-Direct, "Braking resistors don't actually provide braking directly -- rather, they allow a drive to stop a loaded motor faster." Why is this important? Protect your AC or DC drive system from regenerative voltage that can create an over-voltage fault on the drive -- especially with high inertial loads or rapid deceleration.

View the video.

New Digital Static Meter: Precise measurement, easy use

Static electricity isn't just a nuisance; it's a serious threat to manufacturing efficiency, product integrity, and workplace safety. Unchecked static can lead to costly downtime, product defects, material jams, and even hazardous shocks to employees. If static is interfering with your processes, EXAIR's upgraded Model 7905 Digital Static Meter offers an essential first step in identifying and eliminating the problem. With just the press of a button, this easy-to-use, handheld device pinpoints the highest voltage areas in your facility, helping you diagnose static issues before they become a problem.

Static electricity isn't just a nuisance; it's a serious threat to manufacturing efficiency, product integrity, and workplace safety. Unchecked static can lead to costly downtime, product defects, material jams, and even hazardous shocks to employees. If static is interfering with your processes, EXAIR's upgraded Model 7905 Digital Static Meter offers an essential first step in identifying and eliminating the problem. With just the press of a button, this easy-to-use, handheld device pinpoints the highest voltage areas in your facility, helping you diagnose static issues before they become a problem.

Learn more.

New laser cutting modulating strategy tested with Mikrotron high-speed camera

Modulating a laser beam's intensity distribution optimizes energy delivery to the process zone, resulting in better cutting speed, cut edge quality, and cut kerf geometry. Scientists in Belgium have come up with a new method that they say produces better cutting results.

Modulating a laser beam's intensity distribution optimizes energy delivery to the process zone, resulting in better cutting speed, cut edge quality, and cut kerf geometry. Scientists in Belgium have come up with a new method that they say produces better cutting results.

Read the full article.

All-in-one embedded PLC based on Raspberry Pi 4 -- build control applications

The new PLC CPI-PS10CM4 from Contec Co. is a compact embedded programmable logic controller (PLC) that is loaded with CODESYS, the world's most widely used software PLC. This product uses Contec's original single-board computer, which is based on Raspberry Pi's latest embedded module, the Compute Module 4 (CM4). By using the wide range of peripheral devices for Raspberry Pi, such as Contec's CPI Series, you can build various control applications in a PLC language that complies with the IEC 61131-3 international standard.

The new PLC CPI-PS10CM4 from Contec Co. is a compact embedded programmable logic controller (PLC) that is loaded with CODESYS, the world's most widely used software PLC. This product uses Contec's original single-board computer, which is based on Raspberry Pi's latest embedded module, the Compute Module 4 (CM4). By using the wide range of peripheral devices for Raspberry Pi, such as Contec's CPI Series, you can build various control applications in a PLC language that complies with the IEC 61131-3 international standard.

Learn more.

Torque sensors for fastening applications and more

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Learn more.

Wide-angle camera optimized for larger, faster conveyor belts

Wider conveyor belts operating at higher speeds are now commonplace in modern logistics. To keep up, SVS-Vistek is offering a cost-effective alternative to multi-camera systems with its fxo901CXGE 10-GigE color camera featuring the Sony IMX901-AQR wide-aspect global shutter 16.4-megapixel CMOS sensor. Unlike standard cameras, this unit captures targets in a wide field of view while maintaining high resolutions. The 4:1 horizontal aspect ratio allows one fxo901CXGE to replace an entire multi-camera system, removing the need for image synchronization.

Wider conveyor belts operating at higher speeds are now commonplace in modern logistics. To keep up, SVS-Vistek is offering a cost-effective alternative to multi-camera systems with its fxo901CXGE 10-GigE color camera featuring the Sony IMX901-AQR wide-aspect global shutter 16.4-megapixel CMOS sensor. Unlike standard cameras, this unit captures targets in a wide field of view while maintaining high resolutions. The 4:1 horizontal aspect ratio allows one fxo901CXGE to replace an entire multi-camera system, removing the need for image synchronization.

Learn more.

Handheld thermal imager cuts diagnostic time

The FLIR TG268 is a next-generation thermal imager that provides professionals in the utility, manufacturing, electrical, automotive, and industrial sectors with a lightweight, handheld, affordable condition monitoring tool. Latest enhancements include higher temperature ranges, improved resolution, and larger data storage capacity. Go beyond the restrictions of single-spot IR thermometers to view and evaluate hot and cold spots that may signify potentially dangerous issues. Accurately measure temps from -25 to 400 C. Native thermal images improved with Super Resolution upscaling.

The FLIR TG268 is a next-generation thermal imager that provides professionals in the utility, manufacturing, electrical, automotive, and industrial sectors with a lightweight, handheld, affordable condition monitoring tool. Latest enhancements include higher temperature ranges, improved resolution, and larger data storage capacity. Go beyond the restrictions of single-spot IR thermometers to view and evaluate hot and cold spots that may signify potentially dangerous issues. Accurately measure temps from -25 to 400 C. Native thermal images improved with Super Resolution upscaling.

Learn more.

SOLIDWORKS 2025: Sheet metal design top features from an expert

Find out what's new in SOLIDWORKS 2025 when it comes to sheet metal and weldments, and learn some valuable tips and tricks along the way from TriMech. Topics covered include copying cut list properties, bend notches, tab and slot enhancements, groove beads (a new type of weld bead), performance enhancements, and more. When you're done, check out TriMech's full YouTube channel filled with educational material.

Find out what's new in SOLIDWORKS 2025 when it comes to sheet metal and weldments, and learn some valuable tips and tricks along the way from TriMech. Topics covered include copying cut list properties, bend notches, tab and slot enhancements, groove beads (a new type of weld bead), performance enhancements, and more. When you're done, check out TriMech's full YouTube channel filled with educational material.

View the video.

Graphene electrodes may be key to next-gen solar cells

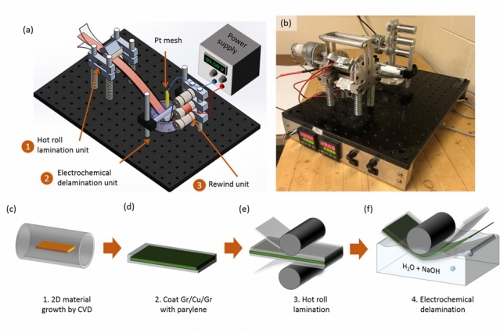

A new roll-to-roll production method could enable lightweight, flexible solar devices and a new generation of display screens.

By David L. Chandler, MIT

A new way of making large sheets of high-quality, atomically thin graphene could lead to ultra-lightweight, flexible solar cells -- and to new classes of light-emitting devices and other thin-film electronics.

The manufacturing process, which was developed at MIT and should be relatively easy to scale up for industrial production, involves an intermediate "buffer" layer of material that is key to the technique's success. The buffer allows the ultra-thin graphene sheet, less than a nanometer (billionth of a meter) thick, to be easily lifted off from its substrate, allowing for rapid roll-to-roll manufacturing.

The process is detailed in a paper published Jun 4 in Advanced Functional Materials by MIT postdocs Giovanni Azzellino and Mahdi Tavakoli; professors Jing Kong, Tomas Palacios, and Markus Buehler; and five others at MIT.

A new manufacturing process for graphene is based on using an intermediate carrier layer of material after the graphene is laid down through a vapor deposition process. The carrier allows the ultra-thin graphene sheet, less than a nanometer thick, to be easily lifted off from a substrate, allowing for rapid roll-to-roll manufacturing. These figures show this process for making graphene sheets, along with a photo of the proof-of-concept device used (b). [Image courtesy: MIT researchers]

Finding a way to make thin, large-area, transparent electrodes that are stable in open air has been a major quest in thin-film electronics in recent years for a variety of applications in optoelectronic devices -- things that either emit light, like computer and smartphone screens, or harvest it, like solar cells. Today's standard for such applications is indium tin oxide (ITO), a material based on rare and expensive chemical elements.

Many research groups have worked on finding a replacement for ITO, focusing on both organic and inorganic candidate materials. Graphene, a form of pure carbon whose atoms are arranged in a flat hexagonal array, has extremely good electrical and mechanical properties, yet it is vanishingly thin, physically flexible, and made from an abundant, inexpensive material. Furthermore, it can be easily grown in the form of large sheets by chemical vapor deposition (CVD) using copper as a seed layer, as Kong's group has demonstrated. However, for device applications, the trickiest part has been finding ways to release the CVD-grown graphene from its native copper substrate.

This release, known as graphene transfer process, tends to result in a web of tears, wrinkles, and defects in the sheets, which disrupts the film continuity and therefore drastically reduces their electrical conductivity. But with the new technology, Azzellino says, "now we are able to reliably manufacture large-area graphene sheets, transfer them onto whatever substrate we want, and the way we transfer them does not affect the electrical and mechanical properties of the pristine graphene."

The key is the buffer layer, made of a polymer material called parylene, that conforms at the atomic level to the graphene sheets on which it is deployed. Like graphene, parylene is produced by CVD, which simplifies the manufacturing process and scalability.

As a demonstration of this technology, the team made proof-of-concept solar cells, adopting a thin-film polymeric solar cell material, along with the newly formed graphene layer for one of the cell's two electrodes, and a parylene layer that also serves as a device substrate. They measured an optical transmittance close to 90 percent for the graphene film under visible light.

The prototyped graphene-based solar cell improves by roughly 36 times the delivered power per weight, compared to ITO-based state-of-the-art devices. It also uses 1/200 the amount of material per unit area for the transparent electrode. There is a further fundamental advantage compared to ITO. "Graphene comes for almost free," Azzellino says.

"Ultra-lightweight graphene-based devices can pave the way to a new generation of applications," he says. "So if you think about portable devices, the power per weight becomes a very important figure of merit. What if we could deploy a transparent solar cell on your tablet that is able to power up the tablet itself?" Though some further development would be needed, such applications should ultimately be feasible with this new method, he says.

The buffer material, parylene, is widely used in the microelectronics industry, usually to encapsulate and protect electronic devices. So the supply chains and equipment for using the material already are widespread, Azzellino says. Of the three existing types of parylene, the team's tests showed that one of them, which contains more chlorine atoms, was by far the most effective for this application.

The atomic proximity of chlorine-rich parylene to the underlying graphene as the layers are sandwiched together provides a further advantage, by offering a kind of "doping" for graphene, finally providing a more reliable and nondestructive approach for conductivity improvement of large-area graphene, unlike many others that have been tested and reported so far.

"The graphene and the parylene films are always face to face," Azzellino says. "So basically, the doping action is always there, and therefore the advantage is permanent."

The research team also included Marek Hempel, Ang-Yu Lu, Francisco Martin-Martinez, Jiayuan Zhao, and Jingjie Yeo, all at MIT. The work was supported by Eni SpA through the MIT Energy Initiative, the U.S. Army Research Office through the Institute for Soldier Nanotechnologies, and the Office of Naval Research.

Published June 2020

Rate this article

View our terms of use and privacy policy