|

| July 14, 2020 | Volume 16 Issue 26 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

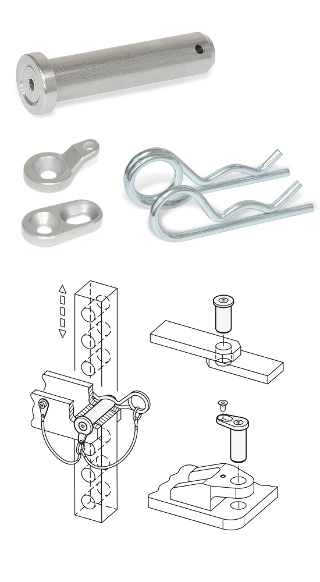

Assembly pins help build in safety

Assembly pins are not new, but JW Winco has been able to make them even better by enhancing fully developed parts according to the application and combining them with other standard securing parts.

Stainless steel assembly pins from the GN 2342 series are available in all common diameters from 8 to 20 mm and in various standardized lengths. Three different end washer forms, and the selection by means of a specific code number between assembly pin with and without transverse spring cotter pin holes, diversify the series even further.

On one of the end washers is a simple, turned stainless steel collar washer that holds the axially inserted assembly pin in the correct position in the hole.

The eyelet washer version, having a hole in which a retaining cable or a ball chain can be attached, protects the assembly pin from getting lost, as well as the matching spring cotter pin, which secures the assembly pin axially through the transverse hole.

The third type of washer offers a fastening tab with an elongated hole. This secures the assembly pin axially, which restricts rotation, and is attached without play using a countersunk screw.

All washers are non-detachable because they are fastened to the assembly pin via their axial countersunk hole. This design favors the implementation of solution-specific special lengths that are available upon request in comparatively low quantities.

Both GN 2344 series washers with protection against loss can also be ordered separately for individual applications, for example, for additional retaining cables or for specific assembly pins.

Because Winco keeps focus on the big picture, they have revised the spring cotter pin as well. The securing element, which is available as GN 1024, is based -- unlike the DIN standard -- on even-numbered wire gauges, which simplifies matching to the associated through hole. The spring cotter pins are available in steel and stainless steel, as well as with single or double winding. With the latter form, the flat spring characteristic curve facilitates easy fitting.

See the full range of JW Winco locking pins here.

Published July 2020

Rate this article

View our terms of use and privacy policy