|

| February 09, 2021 | Volume 17 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Aero: Thermoplastic tape reaches thermoset laydown speeds -- no autoclave required

Using their enhanced Automated Fiber Placement (AFP) processing technology, Electroimpact, a highly experienced provider of factory automation and tooling solutions, was able to increase laydown speeds of thermoplastic uni-directional tape (TP UDT) to 4,000 in./min (IPM). The high-speed rates were made possible by working together with Victrex and relying on the unique properties of the company's VICTREX AE 250 LMPAEK UDT.

The achievement marks a decisive step forward in the production of large structural components from thermoplastic composites for use in aerospace.

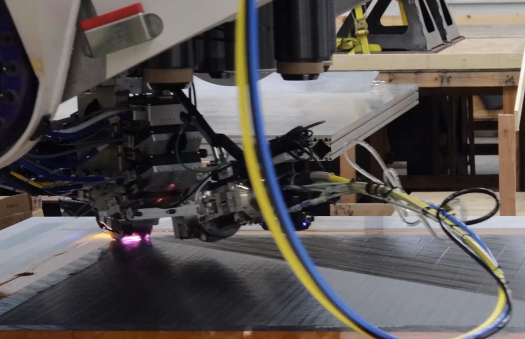

Electroimpact VSS Laser laying VICTREX AE 250 LMPAEK UDT.

Currently, large composite structures in aerospace, such as wings and fuselage, are virtually all thermoset based. However, the challenge with the thermoset composites is that they require a lengthy cure in an autoclave large enough for the structure. The autoclave is a production bottleneck and requires a considerable amount of energy to operate.

With sustainability being an important driver for the aerospace industry, OEMs and suppliers are not only looking to improve fuel efficiency of aircraft but also at improving efficiencies throughout the supply chain. The substantial benefit thermoplastic composites offer has been in the testing process for some time, leading to an increased use of the material in the manufacture of smaller parts. A key advantage is that thermoplastic composites can be processed Out of Autoclave (OoA), so manufacturing processes have been developed to take advantage of their potential for high-speed production. Recyclability of thermoplastic composites is another major benefit.

Electroimpact has enhanced existing AFP processing technology through the deployment of a new laser heating system with the potential to revolutionize thermal processing for the aerospace industry.

"The significance of processing thermoplastic UDT at 4,000 IPM layup speeds with the variable spot size (VSS) laser is, for the first time that we know of, that thermoplastics are able to achieve thermoset layup speeds. These developments can help eliminate the need for autoclave cure [and] offer major and new throughput advantages for thermoplastics," said Michael Assadi, chief engineer at Electroimpact.

"I'm convinced that, based on ongoing in-depth support from Victrex at every stage of the project, high-speed production and high performance of the advanced VICTREX AE 250 UDT will enable the production of large-scale aerospace structural components in the years to come," he added.

VIDEO: This video contains clips of many different Electroimpact Automated Fiber Placement (AFP) systems, including one using a laser heater at the end. [Credit: Electroimpact]

Electroimpact has already gone one step further and trialed in-situ production with VICTREX AE 250 UDT. A test program comparing several different materials demonstrated that the VICTREX LMPAEK UDT delivered the best performance, producing porosity-free laminations including the most dimensionally uniform and even distribution of fiber in the resin. As a result, a high-quality component can be produced without any additional processing steps after layup, eliminating the need for oven consolidation. In-situ manufacturing has long been considered the holy grail for aerospace composite structures.

Source: Victrex

Published February 2021

Rate this article

View our terms of use and privacy policy