|

| January 31, 2012 | Volume 08 Issue 04 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Lightweight, laminated circuits take the heat

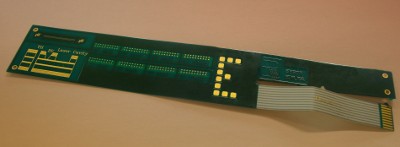

Multilayer printed circuit board using APTIV film/copper foil laminates from Rogers Corporation.

Delamination caused by deteriorating adhesives that traditionally bond the layers of laminate structures can lead to premature product failure. Adhesives often deteriorate when exposed to high temperatures, moisture, or chemicals.

To solve this problem, Rogers Corporation, a manufacturer of high-end specialty materials, developed a proprietary technology to heat laminate, high-temperature-performance Victrex APTIV film directly to metal foils or other materials in both roll-to-roll and flat-panel laminate structures without the need for adhesives.

Eliminating the use of adhesives has numerous benefits, including the reduction of VOCs (volatile organic compounds) during production. This makes the laminate structures more environmentally friendly; reduces the amount of raw materials used compared to adhesive-based systems (creating the potential for an overall systems cost reduction); increases laminate thermal conductivity by elimination of the insulating adhesive layers; and reduces laminate thickness, which allows for miniaturization in smaller, thinner devices. Surprisingly, adhesives can add up to 50% to the overall thickness and weight of a laminate structure, such as a circuit board.

"We developed the proprietary process knowledge primarily for APTIV film," says Koen Hollevoet, business opportunity analyst at Rogers Corporation. "It is the highest-performing, most versatile thermoplastic film available. Victrex APTIV films provide all of the outstanding performance properties of VICTREX PEEK polymer in a thin, flexible format. Victrex Polymer Solutions, the producer of APTIV film, is the only company in the world that is solely dedicated to the manufacture of PEEK polymer-based films."

To produce the adhesive-less laminates, Rogers Corporation installed a new line in its Belgium facility. The production capability supports roll-to-roll laminate structures having a maximum roll length of 400 m (1,312 ft) and a maximum thickness of 0.25 mm (0.10 in.). When the rolls are panelized, a maximum width of 0.61 m (24 in.) and length of 1.22 m (48 in.) is achievable.

Rogers can also produce flat press panels in two sizes: 0.61 m (24 in.) wide x 0.46 m (18 in.) long, or 0.46 m (18 in.) wide x 1.22 m (48 in.) long, with a maximum laminate thickness of 1.5 mm (0.06 in.) in a press. Both proprietary processes allow APTIV film to be combined with metal foils like copper, brass, aluminum, or other materials, including aramid or glass fiber fabrics.

"Our standard product is APTIV film with either copper or aluminum foil on one or both sides," says Hollevoet. "However, we can laminate in a wide variety of configurations. For example, we can produce laminates with A-B, A-B-A, and B-A-B structures. Also, the process is not limited to only three layers of different materials. Basically, we tailor-make any adhesive-free laminate structure combining the required materials with APTIV film, customized to the customer's end-use requirements."

The high-performance characteristics of APTIV film have enabled Rogers to extend its market reach beyond high-frequency radar and telecommunications circuit applications. "The film allows us to operate in very high, continuous-use temperature applications, including those with requirements up to 200°C (392°F), and can withstand lead-free-solder processing temperatures, which can reach extremes of 280°C (536°F)," says Hollevoet. "APTIV film has a very unique combination of properties, including high-temperature and chemical resistance, low moisture absorption, and excellent mechanical and electrical insulation properties, enabling our adhesive-less laminates to function in harsh environments such as those found in a variety of automotive under-the-hood applications, where longer part life leads to higher reliability; in down-hole oil-and-gas applications, where reliability and downtime avoidance are critical; and in aerospace applications where adhesive-less laminates offer improved performance and weight reduction."

Rogers is working with Victrex on non-standard constructions and applications outside the standard printed-circuit-board applications. "Victrex sells into a variety of applications that are not part of our current focus, so our collaboration really benefits customers," says Hollevoet. "If their customers require assistance with lamination, Victrex engages our team to explore how we can cooperatively identify a technical solution, and, by working with them, we are expanding the reach of our processing capability."

Want more information? Click below.

Source: Victrex plc

Published January 2012

Rate this article

View our terms of use and privacy policy