|

| April 13, 2021 | Volume 17 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Researchers claim big advance in 'massless' structural battery tech

Structural battery composites cannot store as much energy as lithium-ion batteries, but they do have several characteristics that make them highly attractive for use in vehicles and other applications. When the battery becomes part of the load-bearing structure, the mass of the battery essentially disappears. [Illustration: Yen Strandqvist]

Researchers from Chalmers University of Technology in Sweden have produced a structural battery that performs 10 times better than all previous versions. It contains carbon fiber that serves simultaneously as an electrode, conductor, and load-bearing material. Their latest research breakthrough paves the way for essentially "massless" energy storage in vehicles and other technology.

The batteries in today's electric cars constitute a large part of the vehicles' weight, without fulfilling any load-bearing function. A structural battery, on the other hand, is one that works as both a power source and as part of the structure -- for example, in a car body. This is termed "massless" energy storage because, in essence, the battery's weight vanishes when it becomes part of the load-bearing structure. Calculations show that this type of multifunctional battery could greatly reduce the weight of an electric vehicle.

The development of structural batteries at Chalmers has proceeded through many years of research, including previous discoveries involving certain types of carbon fiber. In addition to being stiff and strong, these materials also have a good ability to store electrical energy chemically. This work was named by Physics World as one of 2018's 10 biggest scientific breakthroughs.

The first attempt to make a structural battery was made as early as 2007, but so far it has proven difficult to manufacture batteries with both good electrical and mechanical properties.

That has changed. Now, the development has taken a real step forward, with researchers from Chalmers, in collaboration with KTH Royal Institute of Technology in Stockholm, presenting a structural battery with properties that far exceed anything yet seen in terms of electrical energy storage, stiffness, and strength. Its multifunctional performance is 10 times higher than previous structural battery prototypes.

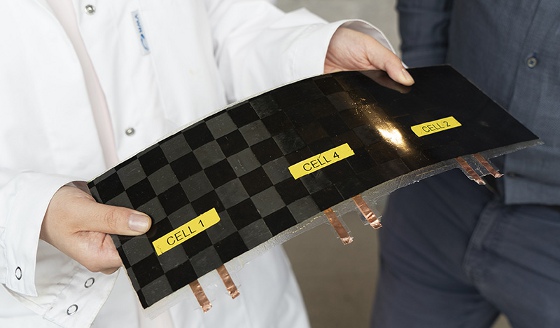

This newly manufactured structural battery cell in Chalmers' composite lab consists of a carbon fiber electrode and a lithium iron phosphate electrode separated by a fiberglass fabric, all impregnated with a structural battery electrolyte for combined mechanical and electrical function. [Image: Marcus Folino]

The battery has an energy density of 24 Wh/kg, meaning approximately 20% capacity compared to comparable lithium-ion batteries currently available. However, the researchers say that since the weight of the vehicles can be greatly reduced, less energy will be required to drive an electric car, and lower energy density also results in increased safety. With a stiffness of 25 GPa, the structural battery can also really compete with many other commonly used construction materials.

"Previous attempts to make structural batteries have resulted in cells with either good mechanical properties or good electrical properties. But here, using carbon fiber, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity," says Leif Asp, professor at Chalmers and leader of the project.

Super-light electric bikes and consumer electronics could soon be a reality

The new battery has a negative electrode made of carbon fiber and a positive electrode made of a lithium iron phosphate-coated aluminum foil. The carbon fiber acts as a host for the lithium and thus stores the energy. Since the carbon fiber also conducts electrons, the need for copper and silver conductors is also avoided, reducing the weight even further. Both the carbon fiber and the aluminum foil contribute to the mechanical properties of the structural battery. The two electrode materials are kept separated by a fiberglass fabric in a structural electrolyte matrix. The task of the electrolyte is to transport the lithium ions between the two electrodes of the battery, but also to transfer mechanical loads between carbon fibers and other parts.

Despite their success in creating a structural battery better than all previous ones, the researchers did not choose the materials to try and break records. Rather, they wanted to investigate and understand the effects of material architecture and separator thickness.

Now, a new project, financed by the Swedish National Space Agency, is underway, where the performance of the structural battery will be increased even further. The aluminum foil will be replaced with carbon fiber as a load-bearing material in the positive electrode, providing both increased stiffness and energy density. The fiberglass separator will be replaced with an ultra-thin variant, which will give a much greater effect -- as well as faster charging cycles. The new project is expected to be completed within two years.

Asp, who is also leading this project, estimates that such a battery could reach an energy density of 75 Wh/kg and a stiffness of 75 GPa. This would make the battery about as strong as aluminum, but with a comparatively much lower weight.

"The next generation structural battery has fantastic potential. If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops, or electric bicycles that weigh half as much as today and are much more compact," says Asp.

In the longer term, it is absolutely conceivable that electric cars, electric planes, and satellites will be designed with, and powered by, structural batteries.

"We are really only limited by our imaginations here," says Asp. "We have received a lot of attention from many different types of companies in connection with the publication of our scientific articles in the field. There is understandably a great amount of interest in these lightweight, multifunctional materials."

You can read the article "A Structural Battery and its Multifunctional Performance" in the scientific journal Advanced Energy & Sustainability Research.

Source: Chalmers University of Technology

Published April 2021

Rate this article

View our terms of use and privacy policy