|

| May 04, 2021 | Volume 17 Issue 17 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New magnesium alloys claimed to reduce weight of heat removal systems by a third

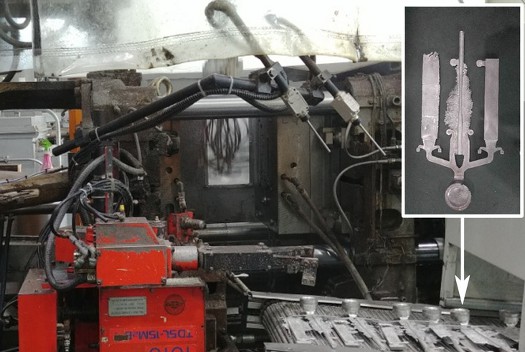

The creators of these new magnesium alloys say the materials' benefits include high thermal conductivity and light weight, which make them excellent choices for replacing aluminum in some applications. [Credits: NUST MISIS]

New alloys created by a partnership between LG Electronics and scientists at a university in Moscow are claimed to help reduce the weight of radiators and heat removal systems in electric vehicles and consumer electronics by one-third.

The research results are published in the Journal of Magnesium and Alloys.

In the development of electronics, the problem of efficient heat removal is becoming more and more acute, and with an increase in the productivity of equipment, heat generation also grows. Reducing the temperature directly affects the prolongation of a device's life cycle. This is especially important for household appliances, electric vehicles, LED panels, and more.

Scientists from NUST MISIS (National University of Science and Technology), in collaboration with LG Electronics, have created new high-heat-conductivity magnesium alloys that differ from their counterparts in increased reliability and low cost. In addition, the materials may be able to reduce the weight of devices significantly.

"Traditionally, aluminum is used for heat removal, but it turns out to be too massive for modern gadgets," said Vyacheslav Bazhenov, associate professor at the Department of Foundry Technology & Artistic Processing of Materials at NUST MISIS. "Reducing the weight of devices can significantly reduce energy consumption during operation, as well as reduce greenhouse emissions during transportation, which is becoming increasingly important today. The use of our alloys will reduce the weight of heat-removing elements by a third without losing efficiency."

Test samples made of new magnesium alloys are shown in the lab at NUST MISIS. [Credits: NUST MISIS]

One of the problems in the operation of magnesium alloys, as noted by the scientists, is their ability to catch fire in the air. Due to the addition of calcium and yttrium, the scientists managed to increase the ignition temperature significantly, so the new materials can be used in various gadgets without restrictions.

"We wanted to create alloys with a low cost, so we were almost not using expensive elements, which are usually alloyed with magnesium -- neodymium, lanthanum, thorium etc.," said Bazhenov. "As a result, we had alloys of two compositions: the cheapest -- alloyed with silicon, zinc, and calcium (Mg-Zn-Si-Ca) with high thermal conductivity and medium strength, and somewhat more expensive -- alloyed with zinc, yttrium, and zirconium (Mg-Zn-Y-Zr) with high strength and slightly lower thermal conductivity."

Based on the results of the work, LG Electronics registered patents for a high-heat-conducting magnesium alloy (Mg-Zn-Si-Ca) developed at NUST MISIS and a radiator made of it in the United States, the European Union, Korea, and China.

The research team is now working on new compositions of magnesium-based alloys that can provide high strength and corrosion resistance along with low cost and high thermal conductivity.

Source: NUST MISIS

Published May 2021

Rate this article

View our terms of use and privacy policy