|

| July 06, 2021 | Volume 17 Issue 25 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

What are piezoelectric active shims?

Due to the piezo element's high resolution down to the nanometer range, active shims cover applications in classical mechanical precision engineering, as well as the alignment of optical components in astronomy, semiconductor manufacturing, and in materials research, employing beam-line instrumentation. Active shims, such as PIRest from Physik Instrumente, are simplifying and speeding up the adjustment process considerably.

By Dr. Mathias Bach and Stefan Vorndran, PI (Physik Instrumente) L.P.

Precision machine tools, laser processing equipment, and optical apparatus are often complex assemblies of different components. The alignment of these components is critical for the overall precision and function of these systems. If a target dimension between two components changes, readjustment may be unavoidable. That can be the case when a machine is put into operation after delivery and tolerances are out of spec due to initial set-up processes, but long-term creep or temperature changes also can have the same effect.

Optical measuring facilities, astronomical devices, wafer processing machines, chip holders, or positioning systems for heavy-precision industrial applications are frequently affected by these issues. Differences on the order of a few microns, or less, can exceed limitations. The classical solution to fix such differences is to use shims, ground exactly to the required tolerances. The fact that they have to be installed -- often at hard-to-reach locations -- can be a time-consuming and expensive disadvantage. Furthermore, this type of adjustment is not infinitely possible, and once the dimension has been fixed it can be very difficult to change it afterwards.

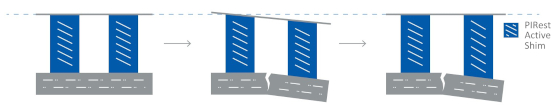

Engineers may often have wished for the possibility to change the thickness of such shims remotely to bring the system back into perfect alignment. With the advent of a new technology, this is no longer wishful thinking. In such cases, piezo-based active shims, or spacers, are a practical solution for the adjustment process. Once installed in the machine, the active shims can readjust the gap between two components at any time with nanometer precision (Figure1).

Figure 1: Aligning parts that have become misaligned due to stress, creep, or settling processes is an application for active shims, when sub-micron or even nanometer precision and stability are required. [Image: PI]

Active shims, such as the new PIRest piezo-based shim, from PI, are a novel alternative, simplifying and speeding up the adjustment process considerably. Due to the piezo element's high resolution, down to the nanometer range, it covers applications in classical mechanical precision engineering, as well as the alignment of optical components in astronomy, semiconductor manufacturing, and in material research, such as conducted with beam-line instrumentation.

Set and forget: High-load capacity

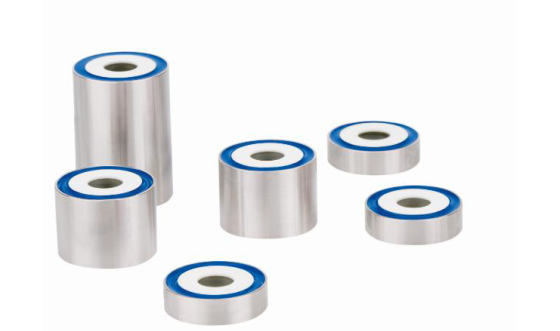

The piezo-based spacers are installed in the machine during its construction. They are available in virtually any shape and size, such as plates, rings, and cylinders, and can be designed to hold heavy loads of several tons (Figures 2 and 2a).

Figure 2: Piezo-based cylinder shims. [Image: PI]

Figure 2a: Built into the machine during its construction, the programmable shims can be manufactured in any geometry and size. [Image: PI]

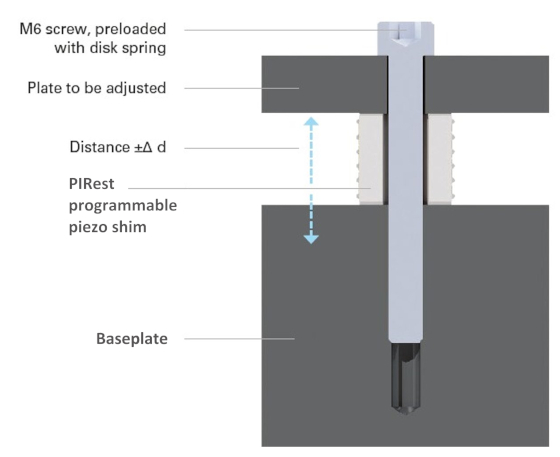

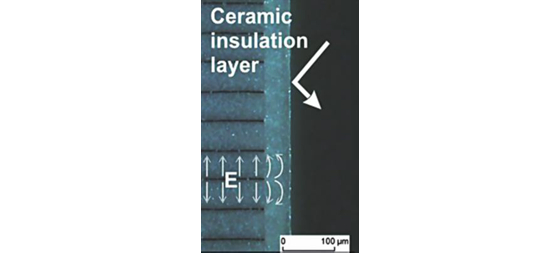

The electro-ceramic core of the PIRest piezo-based shim is manufactured using the patented PICMA® multilayer piezo actuator process -- proven in many earthly applications, as well as working successfully on the MARS Rover for several years, after passing 100 billion cycles of a NASA test program without failures. Here, the piezoceramic active element -- a monolithic block, whose active layers are made up of thin ceramic film -- are protected by an all-ceramic insulating layer to keep environmental influences and humidity out. The durability of this multilayer piezo ceramic technology has been proven time and again in industry, life sciences, microscopy, medical technology, and research (Figures 3 and 3a).

Figure 3: The all-ceramic insulation of PICMA multilayer piezo ceramic elements protects them from environmental influences. [Image: PI]

Image 3a: A large variety of standard shapes and sizes of PICMA multilayer piezo ceramic elements are available. [Image: PI]

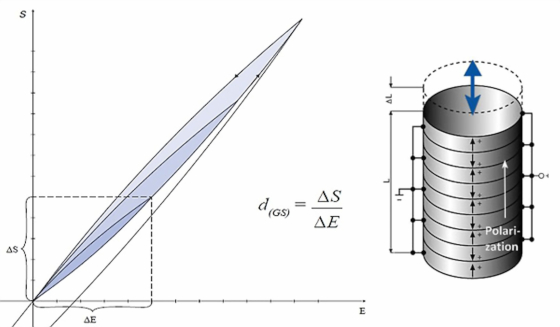

The concept of a piezo ceramic actuator is well understood -- displacement is dependent on electric charge, and by changing the drive voltage the actuator will expand or contract in real time (Figure 4). While drawing negligible power in steady-state operation, the actuator will slowly recede to its "zero" position when the power source is removed.

Figure 4: Conventional piezo actuators: Typical displacement curves (left) of traditional open loop (no position feedback) piezo actuators, and basic design thereof (right). Displacement is roughly proportional to the electric field and when the drive voltage is removed, the displacement will recede to zero, once the element is fully discharged. [Image: PI]

Active shims with nanometer resolution and long-term stability

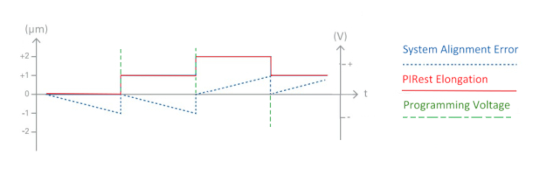

Displacement of PIRest is programmed with a specific control tool, and remains after disconnect from the power source (Figure 5) -- comparable to a self-locking screw-type actuator, but at much higher precision and without the creep.

Figure 5: Set-and-forget behavior of PIRest active shims. Misalignment caused by initial settling processes (during the installation of a machine), temperature changes, or long-term creep effects may make it necessary to readjust machine components when they exceed a certain tolerance threshold. Piezo-based, active shims can compensate alignment errors easily and remotely, without the need for a permanent power source and control voltage. Every time a misalignment occurs, the shim is reprogrammed by the required amount. [Image: PI]

A voltage connector for programming is provided with the active shim -- it only needs to be connected shortly for each respective adjustment. The necessary cables can be considered during design of the machine and become a permanent part of the system. After adjusting, the desired position remains stable without power, and the power supply can then be disconnected. The displacement stability only depends on the change of ambient temperature. Long-term tests in an environment within +/- 1 K temperature change using an actuator with 10 µm nominal adjustment range, indicated a position drift of less than +/- 100 nm, irrespective of the displacement. As an option, the active shims can also be equipped with a temperature sensor. Skillful combination of the active shims makes it possible to adjust in up to six degrees of freedom.

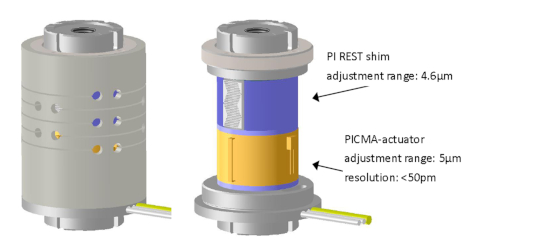

If required, active shims can also be combined with classical piezo actuators (Figure 6). Typical applications for these types of hybrid systems include dynamic vibration compensation, readjusting the focal plane during an optical measuring or scanning process, as well as controlling a laser beam in metrology systems or materials processing.

Figure 6: Hybrid combination of traditional piezo stack actuator for highly dynamic motion (bottom, orange) and programmable shim (top, blue). [Image: PI]

Learn more at physikinstrumente.nl/en/products/linear-actuators/pirest-active-piezo-shims/.

About Physik Instrumente L.P.

Physik Instrumente L.P. (PI) is a leading manufacturer of nanopositioning, linear actuators, and precision motion-control equipment for photonics, nanotechnology, semiconductor, and life science applications. PI has been developing and manufacturing standard and custom precision products with piezoelectric and electromagnetic drives for over 40 years. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. PI has a worldwide presence with 10 subsidiaries and over 750 staff.

For more information, please contact Stefan Vorndran, VP Marketing for Physik Instrumente L.P.; 16 Albert St., Auburn, MA 01501; Phone 508-832-3456, Fax 508-832-0506; email stefanv@pi-usa.us; www.pi-usa.us.

Published July 2021

Rate this article

View our terms of use and privacy policy