|

| February 14, 2012 | Volume 08 Issue 06 |

Sensor News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Laumas load cells and electronics from AutomationDirect

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Learn more.

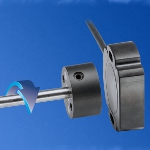

Torque sensors for fastening applications and more

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Learn more.

Real-world applications: FUTEK 100 sensor examples

Get inspired. FUTEK has more than 100 real-world application examples for their load cells, force transducers, torque sensors, pressure sensors, and multi-axis sensors. From a cryogenic load cell on the Mars Curiosity rover to fly-by-wire multi-axis force and torque sensors for aircraft, learn about sensor systems, their specs, and design. Automotive, manufacturing, medical, robotics, and automation are covered too. Fascinating and highly practical.

Get inspired. FUTEK has more than 100 real-world application examples for their load cells, force transducers, torque sensors, pressure sensors, and multi-axis sensors. From a cryogenic load cell on the Mars Curiosity rover to fly-by-wire multi-axis force and torque sensors for aircraft, learn about sensor systems, their specs, and design. Automotive, manufacturing, medical, robotics, and automation are covered too. Fascinating and highly practical.

Learn more.

Ultra-compact hollow-shaft angle sensor tracks angle even if power is cut

Novotechnik's WAL 200 Series of hollow shaft angle sensors provides absolute rotary position -- even if power is removed. After power is restored, this sensor provides the correct angle. With a 7-mm profile and 22-mm diameter, it is designed to fit in applications with very limited space. The WAL 200 Series has a measurement range of 0 to 340 degrees. Mechanical range is a continuous 0 to 360 degrees. Applications include volumetric dosing systems, joysticks, and more.

Novotechnik's WAL 200 Series of hollow shaft angle sensors provides absolute rotary position -- even if power is removed. After power is restored, this sensor provides the correct angle. With a 7-mm profile and 22-mm diameter, it is designed to fit in applications with very limited space. The WAL 200 Series has a measurement range of 0 to 340 degrees. Mechanical range is a continuous 0 to 360 degrees. Applications include volumetric dosing systems, joysticks, and more.

Learn more.

High-res image sensor for automotive ADAS and AD

OMNIVISION has expanded its TheiaCel™ product portfolio with a new OX12A10 12-MP high-res image sensor for automotive cameras. This sensor, with the highest resolution in its line, improves automotive safety by eliminating LED flicker regardless of lighting conditions. It is ideal for high-performance front machine vision cameras for advanced driver assistance systems (ADAS) and autonomous driving (AD).

OMNIVISION has expanded its TheiaCel™ product portfolio with a new OX12A10 12-MP high-res image sensor for automotive cameras. This sensor, with the highest resolution in its line, improves automotive safety by eliminating LED flicker regardless of lighting conditions. It is ideal for high-performance front machine vision cameras for advanced driver assistance systems (ADAS) and autonomous driving (AD).

Learn more.

Durable, full redundant angle sensors for automotive and off-highway

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Learn more.

Mini linear position sensor for drones, robots, aero, more

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

Learn all the specs.

Touchless angle sensors get CAN SAE J1939 interface

Novotechnik has added the CAN J1939 interface (developed for heavy-duty vehicles) to its RFC4800 Series of touchless angle sensors measuring angular position up to 360°, turn direction, turns, speed, and operational status. It can provide one or two output channels. It has a longer life and robustness than an optical encoder. It can signal if a sensor needs replacing or average a programmable number of values to output to reduce external noise if present. This is wear-free angle measurement made easy.

Novotechnik has added the CAN J1939 interface (developed for heavy-duty vehicles) to its RFC4800 Series of touchless angle sensors measuring angular position up to 360°, turn direction, turns, speed, and operational status. It can provide one or two output channels. It has a longer life and robustness than an optical encoder. It can signal if a sensor needs replacing or average a programmable number of values to output to reduce external noise if present. This is wear-free angle measurement made easy.

Learn more.

Radar level sensor monitors liquids and powders

The innovative FR Series non-contact radar level sensor from Keyence has been designed to monitor the level of both liquid and powder in any environment. This sensor features short- and long-range models, as well as chemical and sanitary options to address a wide array of level sensing applications. Works even when obstructions or harsh conditions are present, such as build-up, steam, or turbulence.

The innovative FR Series non-contact radar level sensor from Keyence has been designed to monitor the level of both liquid and powder in any environment. This sensor features short- and long-range models, as well as chemical and sanitary options to address a wide array of level sensing applications. Works even when obstructions or harsh conditions are present, such as build-up, steam, or turbulence.

Learn more.

Mini tunnel magneto-resistance effect sensors

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Learn more.

Real-world applications: FUTEK 100 sensor examples

Get inspired. FUTEK has more than 100 real-world application examples for their load cells, force transducers, torque sensors, pressure sensors, and multi-axis sensors. From a cryogenic load cell on the Mars Curiosity rover to fly-by-wire multi-axis force and torque sensors for aircraft, learn about sensor systems, their specs, and design. Automotive, manufacturing, medical, robotics, and automation are covered too. Fascinating and highly practical.

Get inspired. FUTEK has more than 100 real-world application examples for their load cells, force transducers, torque sensors, pressure sensors, and multi-axis sensors. From a cryogenic load cell on the Mars Curiosity rover to fly-by-wire multi-axis force and torque sensors for aircraft, learn about sensor systems, their specs, and design. Automotive, manufacturing, medical, robotics, and automation are covered too. Fascinating and highly practical.

Learn more.

Rugged sensor measures surface temperatures

TDK's tiny new T850 SMT NTC sensor measures surface temperatures for applications such as heat sinks of power modules and monitoring of industrial processes. It combines high humidity resistance with fast response time due to excellent thermal coupling to the target. The sensor is suitable for harsh environments with temps from -40 C to 150 C and is waterproof to 500 hrs.

TDK's tiny new T850 SMT NTC sensor measures surface temperatures for applications such as heat sinks of power modules and monitoring of industrial processes. It combines high humidity resistance with fast response time due to excellent thermal coupling to the target. The sensor is suitable for harsh environments with temps from -40 C to 150 C and is waterproof to 500 hrs.

Learn more.

Position sensor real-world applications: Automotive and mobile equipment

From firetruck nozzle positioning and race car steering to accelerator control and wheel vector sensing, learn how position sensors from Novotechnik are used in real-world applications. Sensor types include non-contacting rotary sensors, angle sensors, and magnetic encoders. We love when manufacturers provide examples of their products in action.

From firetruck nozzle positioning and race car steering to accelerator control and wheel vector sensing, learn how position sensors from Novotechnik are used in real-world applications. Sensor types include non-contacting rotary sensors, angle sensors, and magnetic encoders. We love when manufacturers provide examples of their products in action.

Learn more.

Detecting part errors: Automotive resistance welding machines

NewTek Sensor Solutions has designed a custom linear variable differential transformer (LVDT) position sensor for resistance spot welding machines used in automotive plants to detect missing or misaligned parts in nut and stud welding. Cars contain hundreds of welded nuts and studs that hold them together. Properly securing the right nut and stud to different car components is critical to safe operations.

NewTek Sensor Solutions has designed a custom linear variable differential transformer (LVDT) position sensor for resistance spot welding machines used in automotive plants to detect missing or misaligned parts in nut and stud welding. Cars contain hundreds of welded nuts and studs that hold them together. Properly securing the right nut and stud to different car components is critical to safe operations.

Read the full article.

What can you do with touchless magnetic angle sensors?

Novotechnik has put together a really informative video highlighting real-world applications for their RFC, RFE, and RSA Series touchless magnetic angle sensors. You may be surprised at the variety of off-highway, marine, material handling, and industrial uses. You'll learn how they work (using a Hall effect microprocessor to detect position) and their key advantages, including eliminated wear and tear on these non-mechanical components. We love when manufacturers provide such useful examples.

Novotechnik has put together a really informative video highlighting real-world applications for their RFC, RFE, and RSA Series touchless magnetic angle sensors. You may be surprised at the variety of off-highway, marine, material handling, and industrial uses. You'll learn how they work (using a Hall effect microprocessor to detect position) and their key advantages, including eliminated wear and tear on these non-mechanical components. We love when manufacturers provide such useful examples.

View the video.

RoboCopters summoned by iPad apps are already in the works for U.S. Navy and Marines

By Grace Jean, Office of Naval Research

Marines running low on ammo may one day use an app on their digital handhelds to summon a robotic helicopter to deliver supplies within minutes, enabled by technologies from a new Office of Naval Research (ONR) program.

The Autonomous Aerial Cargo Utility System (AACUS) is a five-year, $98 million effort to develop sensors and control technologies for robotic vertical take-off and landing aircraft.

"AACUS is a leap-ahead technology that allows the Navy and the Marine Corps to move beyond having a highly trained operator fly an unmanned aircraft," says Rear Adm. Matthew Klunder, chief of naval research. "The program will let us leverage advanced autonomy, but still maintain the central and critical role of the human operator as the supervisor."

Marines based at outposts or in the field will be able to request the autonomous cargo helicopters for rapid resupply of combat essentials.

"We want to turn any helicopter into a logistics machine," says Dr. Mary "Missy" Cummings, program officer for AACUS, ONR's newest innovative naval prototype. "In the near term, we want to succeed in fully autonomous landings in austere locations, so Marines can get whatever they need on demand.

"In the long term, this could be a real life saver and revolutionize first response," she says. While rapid resupply is the immediate focus for AACUS, long-term applications could include critical medical missions such as casualty evacuation."

Program officials are seeking researchers who will develop threat- and obstacle-detection and avoidance systems, as well as autonomous landing capabilities that can operate across different types of aircraft. They expect teams from industry and academia to join forces to compete for the contracts.

Proposals are due Feb. 22. Officials plan to award up to two contracts in April.

The effort follows the Marine Corps Warfighting Laboratory's successful program to develop an unmanned system capable of hauling cargo semi-autonomously to landing zones at bases. The prototype, called K-MAX, flew its first combat mission in Afghanistan in mid-December, resupplying Marines with cargo carried in a sling-load.

AACUS, on the other hand, is aimed at internal load-carrying capacity. It will be a major leap ahead in autonomy, says Cummings. While K-MAX requires a trained operator within line-of-sight to fly, any operator will be able to call for AACUS from any location.

"It's going to be designed to work with people who have no flight experience," she says. "An operator will pick up his iPad or Android and make an emergency supply request. He'll request that the helicopter come to him and land as close to him as possible."

The helicopter not only will take off by itself, but will plan its own flight path and navigate its way through the airspace, requiring little to no input from an operator other than to verify its proposed landing site. The concept will require improvement in data processing.

"How you take the data from sensors and integrate them to make these decisions that's one of the big leaps," says Cummings. "It's like putting a frontal lobe on the helicopter."

Published February 2012

Rate this article

View our terms of use and privacy policy