|

| August 10, 2021 | Volume 17 Issue 30 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Toshiba positively evaluates no-solder connector tech for IOT

Toshiba Electronic Devices & Storage Corp. has developed two connector technologies that allow easy, solder-free assembly of small IoT nodes, which are regarded as essential for realization of the "Trillion-Node Engine," an open-source IoT platform that could connect billions of devices in the future.

Tests of the connector have resulted in positive evaluations. Toshiba will continue to develop them and will use them in a demonstration unit for Toshiba's motor control drivers.

The future of the Internet-of-Things (IoT) is expected to be driven not only by expert engineers developing IoT devices for industry, but also by non-engineers creating IoT devices to handle all kinds of tasks. Realizing this will require an IoT development platform that allows individuals to quickly and easily embody their ideas and to create IoT prototypes, which will support the development of small, lower power IoT sensor nodes that can be customized to handle various functions and applications. Toshiba and the University of Tokyo are currently evaluating the Trillion-Node Engine as an open IoT platform, and have found it to offer strengths in terms of ease of use.

One notable challenge to be overcome is further miniaturization of IoT nodes -- particularly their connectors. They are currently comparatively large and require precise soldering by a professional. If an IoT system connects printed circuit boards (PCBs) and motors, a wire harness is needed between the PCBs and motors. The common connection between the wire harness and PCBs today results in a terminal block that is 8 mm high, which is too large for an IoT platform.

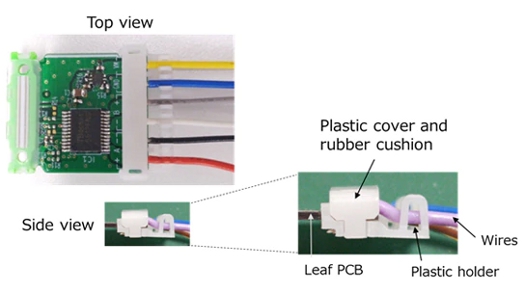

In response, Toshiba has developed the Bare Wire Connection Mechanism (BWCM), which uses two connector technologies. The first is an original U-shaped structure of plastic holders to align wires on PCBs. The wires are fixed to the pads with a second technology of rubber cushions and plastic covers; current covers are made of metal.

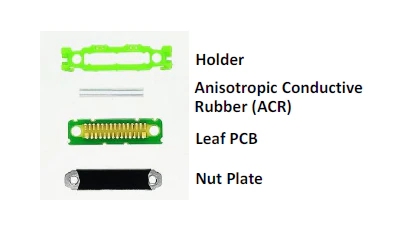

Components of rubber connectors.

BWCM realizes a small wire connection without any soldering, with a height on the PCB of just 2 mm, smaller than conventional terminal blocks. Toshiba's investigation on the retention strength of the wires and PCB confirmed a tensile force of over 3N, which is stable enough for practical use.

An example of an IoT module with the new connect technologies.

Toshiba has made trial Leaf PCBs, the PCB developed for the Trillion-Node Engine, and sample IoT systems to evaluate the strength of the rubber connectors on Leaf PCBs. Tests, including high-temperature and high-humidity testing, confirmed the reliability and stability of the rubber connectors.

An example of a wire connecter between motor control PCBs and motors.

The two connect technologies were realized through Toshiba's packaging technology for semiconductor and HDDs, system LSI signal connect technology, and IoT system design technology, along with the University of Tokyo's research in electronics and design technology for low-power IoT systems.

Details of the technologies were reported at 2021 IEEE 71st Electronic Components and Technology Conference (ECTC 2021), an international conference on microelectronic packaging, components, and systems technology held online. The presentation was called, "Novel Connector Mechanism Using Anisotropic Conductive Rubber for Trillion-Node Engine as an IoT Edge Platform." In its evaluation of the technologies, Toshiba used research results from a project subsidized by the New Energy and Industrial Technology Development Organization.

Source: Toshiba

Published August 2021

Rate this article

View our terms of use and privacy policy