|

| September 07, 2021 | Volume 17 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Universal Robots takes cobot welding to the next level at FABTECH 2021

Universal Robots pioneered collaborative arc welding and continues to make cobot-powered fabricating solutions mainstream. FABTECH 2021 is the launchpad for innovative new cobot applications including heavy-duty water-cooled welding, hardfacing, plasma cutting, and flexible machine loading.

FABTECH 2017 was a milestone year as the first welding systems based on Universal Robots (UR) threw sparks at the show and officially entered the market. Flash forward to 2021, and UR cobot-powered systems are mainstream at FABTECH (which will be held Sept. 13-16), where numerous OEMs and UR+ partners will be actively selling MIG, TIG, and plasma welding and cutting solutions, making it one of the fastest growing markets for UR cobots.

"For 40 years, robotic arc welding evolved incrementally," says Joe Campbell, senior manager of Applications Development and Strategic Marketing at Universal Robots. "Collaborative arc welding is the first disruptive technology to hit the robotic arc welding market since the introduction of DC servo-powered robots." Campbell attributes the rapid market traction to several key drivers, including a significant welder shortage, an increase in high-mix/low-volume production, and the fact that cobot welders are easy to deploy, quickly producing parts with improved quality and consistency.

Visitors to FABTECH in Chicago will find the flagship blue cobots in more than 20 booths throughout the show and are encouraged to start their cobot discovery at Universal Robots' own FABTECH booth B-17012.

---------------------------------

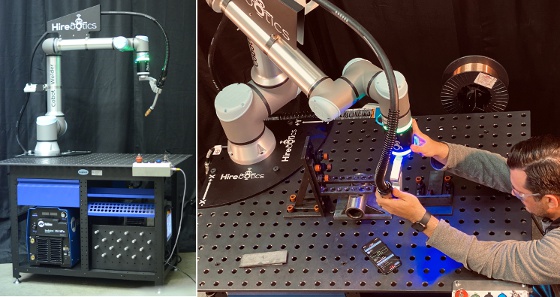

Have a smartphone? You can program a cobot welder

"We show attendees how easy it is to program a Universal Robot for fabricating applications -- and we'll hand out show maps featuring our partners exhibiting welding, cutting, grinding, press brake, and machine-loading solutions and components that exemplify this," says Campbell, who will also be hosting demonstrations of several innovative solutions in UR's own booth. These include Hirebotics' new Cobot Welder, a complete, user-friendly cobot welding system that enables painless, automated MIG welding deployments. Using the ingeniously simple Cobot Welder cellphone application that runs on Hirebotics' cloud-based Beacon software platform, FABTECH attendees will experience how easy it is to teach new parts and welds.

Cobots take on heavy-duty tasks

Heavy-duty welds are now possible to perform with cobots thanks to Vectis Automation, which has become the first UR partner in North America to develop a water-cooled, cobot-based welding system in a new version of its Cobot Welding Tool. Showcased at FABTECH, the Cobot Welding Tool now comes with a MultiPass Software Feature and ArcPilot Through-The-Arc Seam Tracking. The solution is now not only compatible with Miller welding equipment but can be integrated with Lincoln and Fronius welding equipment too.

Vectis Automation has pioneered the use of a UR cobot for hardfacing, the metalworking process where harder or tougher material is applied to a base metal. At Vectis' own FABTECH booth B17054, the company will also debut new UR cobot-powered plasma cutting, featuring Vectis' Cobot Cutting Tool with Hypertherm PowerMax able to perform complex cuts on 3D shapes and large structures for a fraction of the cost of a tube laser.

---------------------------------

Application kit automates CNC milling with cobots

The UR booths will also host new solutions for automated machine tending, featuring the new VersaBuilt CNC Mill Application Kit for manufacturers seeking a plug-and-play approach to CNC milling automation. Versabuilt's UR+ Application Kit comes with all components pre-assembled and has been designed to get the CNC mill and the UR10e cobot working together, automating the loading and unloading of parts into the mill. The VersaBuilt Kit requires no programming experience. It features easy-to-use automation software that allows the machinist to simply enter part dimensions and CNC milling program numbers to get the application up and running.

---------------------------------

Flexible machine loading for unstructured parts; more payload with longer reach

FABTECH attendees looking for flexible, intelligent machine-loading solutions for unstructured parts in bins should check out Universal Robots' ActiNav, a new system showcased at the UR booth that combines intelligent vision and real-time autonomous motion control with Universal Robots' e-Series cobots.

Before ActiNav, solutions for unstructured picking and placing of parts into machines were solely focused on the vision aspect, often requiring complex programming to bridge the gap from "pick" to "place" -- especially if the "place" is not just dropping into a box but accurately inserting parts into fixtures for further processing.

ActiNav changes all that, combining real-time autonomous motion control, UR cobots, vision, and sensor systems into one seamless Application Kit that solves the bin-picking challenge in machine-tending applications.

At FABTECH, ActiNav will pick metal parts randomly jumbled in bins and correctly insert them into a machine. Powering ActiNav is the new enhanced version of UR's best-selling UR10e cobot, now featuring 25% more payload capacity with the ability to lift 12.5 kg (27.55 lb), providing customers with exciting new deployment capabilities.

VIDEO: ActiNav boosts competitiveness and extends lifespan of legacy equipment at PrecisionForm.

Source: Universal Robots

Published September 2021

Rate this article

View our terms of use and privacy policy