|

| December 28, 2021 | Volume 17 Issue 48 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

All about smart hybrid actuators -- they combine nanometer precision, large forces, and long travel ranges with high dynamics

By Oliver Dietzel, Team Leader for Project Management Corporate Platform Development,

PI (Physik Instrumente)

Hybrid drives combine two different drive concepts into a high-performance and precision positioning system. They take advantage of both drives. These types of solutions are always in demand when one drive alone is not in a position to meet all of the requirements of applications. An example of this is nanometer-precision positioning of heavy loads over long travel ranges. Nanopositioning systems that combine piezo drives with classical drive screws, therefore, offer a practical solution, but other drive concepts are also possible. Examples of applications for hybrid drives range from semiconductor manufacturing through quality assurance and optical inspection to biomedical engineering.

Hybrid concept with electric motor and voice coil

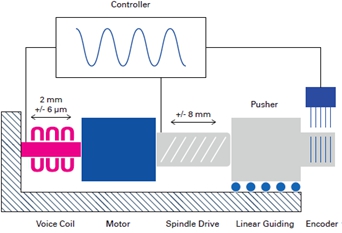

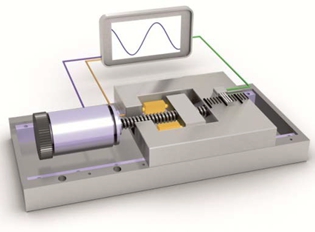

Various concepts have already been developed and implemented for hybrid positioning systems. One solution, for example, is a combination of linear motors and voice coil actuators (Figure 1).

Figure 1: Hybrid concept with electric motor and voice coil actuator. [Image: PI]

Linear motors offer long travel ranges with high positioning accuracy and repeatability, but do have the disadvantage of high friction in the linear guides used for taking up the load. Nevertheless, voice coil actuators do provide precision positioning as well as good force control and smooth motion. However, their travel range is limited to 100 mm, and they can only hold loads at rest when they are powered on.

Hybrid concept with piezo walking drive and piezo actuator

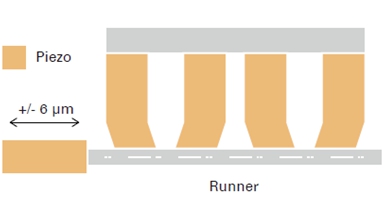

PI has already successfully developed and established a further hybrid drive concept for other applications, such as those for inspecting semiconductors. A PiezoWalk® drive that offers long travel ranges with high stiffness is combined with a PICMA® actuator for high dynamics applications (Figure 2). The advantage in this case is, depending on the design of the PiezoWalk drive, the possibility of realizing high holding forces. In this case, the high dynamics of the PICMA drive are important for fast focusing of the object to be scanned.

Figure 2: Hybrid concept with piezo walking drive and piezo actuator. [Image: PI]

Hybrid concept with electric motor and piezo actuator

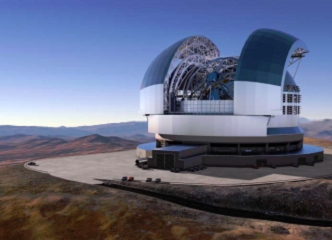

PI is working on a project together with engineers and astronomers from the European Southern Observatory (ESO) that will result in the world's largest terrestrial telescope on the 3,000-m-high Cerro Amazones mountain in the Atacama Desert in Chile (Figure 3). According to the latest updates from ESO, the telescope is planned to deliver the first scientific observations in September 2027, about half a year after an initial "telescope technical first light."

Figure 3: The European Extremely Large Telescope (ELT) will be the largest terrestrial telescope for scientific evaluation of electromagnetic radiation in the visible and near-infrared wavelength range. [Image: ESO]

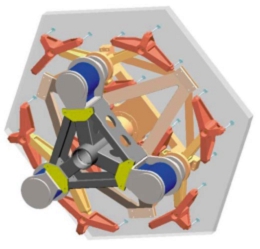

The telescope's revolutionary design consists of a main mirror (M1) with a diameter of 39 m, which is divided into 798 independent mirror segments. Each mirror segment has a diameter of 1.4 m and is positioned by three independent hybrid drives with a nominal travel range of +/- 5 mm (Figure 4).

Figure 4: Depiction of a main mirror segment from ELT, the three hybrid drives are shown here in blue. [image ESO]

Considerable masses must be moved for this: Each mirror segment including its support weighs approximately 551 lb. Due to the different alignments of the telescope, a total of 2,394 actuators need to be able to move and hold loads with push/pull forces between 463 N and 1,050 N (Figure 5).

Figure 5: Conceptual design of the ELT M1 Segment Subunit. [Image: ESO]

One of the most important tasks of the telescope will be to supply the sharpest possible images of the universe, which researchers can use to search for exoplanets, i.e., planets that exist beyond our solar system. Therefore, the greatest technical challenge will be to move the mirror segments over the entire range with a maximum position deviation of 2 nm.

Figure 6: The electric motor is suitable for heavy loads and long travel ranges. In conjunction with a piezo drive, the hybrid system also provides additional positioning accuracy in the subnanometer range. [Image: PI]

In order to achieve this high path accuracy, PI developed a hybrid concept where a motor drive screw suitable for heavy loads and long travel ranges, is combined with a piezo actuator (Figure 6). Serial combination of both very different drives results in a powerful and high-precision positioning system (Figure 7).

Figure 7: Very stiff hybrid linear actuator with a diameter of approx. 200 mm and an overall length of approximately 285 mm. [Image: PI]

Piezo actuators position with subnanometer accuracy

Precision motion that results when an electrical voltage is applied to a piezoelectric material is of particular importance for nanopositioning. The electrical power is converted into mechanical energy directly inside the crystalline solid state, which means that there are no rotating or frictional parts.

The piezo actuators not only work with high precision but are also maintenance- and wear-free. They can move large loads with weights up to several tons. Electrically, they act as capacitive loads and need virtually no power in static operation. The behavior in the power circuit is very much like an electrical capacitor. Similar to capacitors, they do not generate any heat in a static condition.

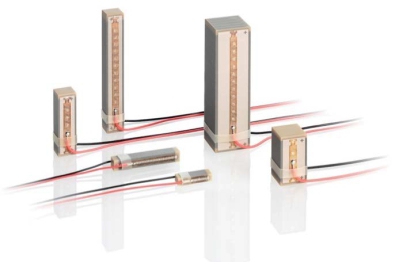

The lifetime of piezo actuators is also convincing: In the case of PICMA multilayer actuators (Figure 8), the active layers consist of thin ceramic films and are surrounded by an all-ceramic insulating layer that protects the actuators against air humidity and failure from leakage current. The monolithic piezoceramic block of such an actuator is very reliable -- even under extreme ambient conditions and high temperature differences.

Figure 8: All-ceramic insulated, high-power piezo actuators are durable even under difficult operating conditions in industry, life science and microscopy, as well as in medical technology and research. [Image: PI]

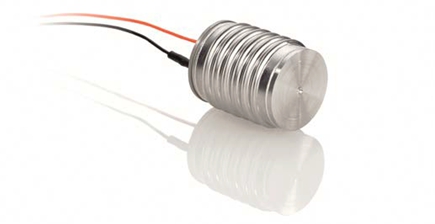

Figure 9: An encapsulated PICMA linear actuator of part of the hybrid drive concept. [Image: PI]

A high-resolution sensor for both drive systems

A further feature of the hybrid drives is the common high-resolution sensor, which helps to control both drives simultaneously and continuously. This is the only way to implement the high resolution of the piezo actuators over the entire travel range.

The high-resolution sensor is an incremental optical encoder that is placed near to the drive axis (Figure 10). It operates at a resolution of 0.1 nm and is also not sensitive to the changing environmental conditions prevailing at the telescope's location in the desert.

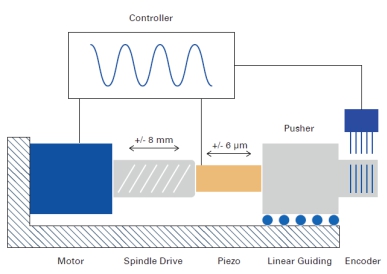

Figure 10: Schematic diagram of the hybrid drive. The common control with one single high-resolution linear encoder allows an extremely constant velocity with high positioning accuracy.[Image: PI]

The motor drive screw is suitable for heavy loads and long travel ranges starting at a few millimeters and going up to one meter. The piezo actuator provides a nominal displacement of approximately 0.1 to 0.15 percent of the actuator length, but nevertheless, achieves a positioning accuracy in the subnanometer range with one high-resolution sensor, and can therefore compensate for the inaccuracies of the motor drive screw.

The drive screw is driven by a brushless, high-torque motor via a high-ratio reduction gearhead.

The gearhead ensures zero-play operation and guarantees a constant transmission ratio. The motor can, therefore, be very small -- even though large masses have to be moved. The high transmission also supports self-locking of the motor when at rest.

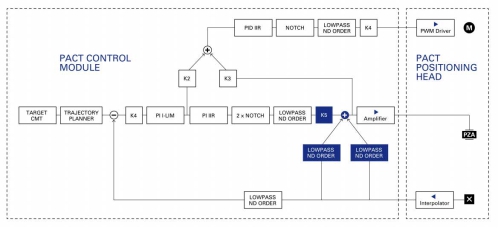

A dedicated controller controls both drives simultaneously and also controls the high-resolution position measuring system. The servo-algorithms consider the motor and the piezo system as a single drive unit and compare the actual motion with a calculated trajectory.

Figure 11: The controller structure. [Image: PI]

The control principle of the hybrid drive is easy to understand (Figure 11). The motor voltage is derived from the control voltage of the piezo. The greater this voltage, the faster the motor runs. When the piezo expands, the motor drives the drive screw in the same direction. In this way, the rough positioning of the drive screw is supplemented by the fine positioning of the piezo. At the same time, the drive screw always moves the piezo near to its zero position automatically. This gives it the best chance of correcting the position in both directions. In this way, relatively long travel ranges can be combined with an extremely high positioning accuracy.

The characteristics of these types of hybrid drives are not only useful for telescopes, but are always a practical solution when a position needs to be detected with high precision and moved repeatedly over long travel ranges, or when a target position needs to be reached with nanometer precision. Other typical application areas include measuring technology or surface inspection, semiconductor manufacturing, microscopy, and laser technology.

About PI

PI is a leading manufacturer of nanopositioning, linear actuators, and precision motion-control equipment for photonics, nanotechnology, semiconductor, and life science applications. PI has been developing and manufacturing standard and custom precision products with piezoelectric and electromagnetic drives for over 40 years. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. PI has a worldwide presence with 10 subsidiaries and over 750 staff.

Published December 2021

Rate this article

View our terms of use and privacy policy