|

| January 04, 2022 | Volume 18 Issue 01 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

When glass or plastic can't cut it: Transparent ceramics solve critical design challenges

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

→ Contact Jackson Evans, Sales Engineer at INSACO jpe@insaco.com.

→ Learn more about INSACO materials and capabilities.

New aero and defense PEKK-based FDM polymers from Stratasys

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Learn more.

EOS expands its Nickel superalloys for 3D printing

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

Learn more.

CNC machining: How to avoid high costs on thin walls

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Read the full article.

Eco-friendly thermoplastic: Light, rigid, strong, damping

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Learn more.

Sound-dampening foam with an eco edge

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

Learn more.

Fastest large-format SLA 3D printer in the world

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Learn more.

Keypad teardown and design insights with Autodesk and Xometry

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Watch this Xometry webinar at your convenience.

Tube cutting and bending design guide: Xometry

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Learn more.

SPEE3D develops ultra-corrosion-resistant alloy

-- a game-changer for maritime additive manufacturing

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Read the full article.

New polymer bearings are PFAS- and PTFE-free

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

Learn more.

New high-speed PSLA 270 printer from 3D Systems

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

Learn more including materials and build sizes.

Customizing Harleys requires top-quality CNC machines

Big-front-wheel Harleys are a trendy thing, but you can't have one built just anywhere. This one was built by Kodlin Motorcycle. [Photo Credit: Siemens AG/P. Klingauf]

Kodlin Motorcycle in Germany customizes motorcycles based upon bikes from the legendary American brand Harley-Davidson. Sophisticated technology and an easy-to-use control system are essential for this way-out work, which is why the company chose the Sinumerik 828D CNC from Siemens.

The Kodlin family has motorcycles in its blood. Master blacksmith Fred Kodlin gave his son Len his first motocross bike for his fifth birthday. There was never really any question about what Len would do when he grew up. Today, the father-and-son team runs the Fred Kodlin Motorcycle workshop, founded by Fred Kodlin back in 1984, in the small town of Borken in the German state of Hessen.

The company is highly specialized; together, father, son, and 10 employees customize Harley-Davidson motorcycles. Up to 50 motorcycles leave their shop floor each year, to the great excitement of their new owners. Many customers simply want to have their series-produced bikes adjusted to suit them better, or to look more personalized. Other customers come to the company looking for bigger modifications, such as the installation of a huge front wheel, which has a very striking effect and is popular among some Harley-Davidson fans.

Milled decorative aluminum elements give Kodlin bikes an individualized touch. [Photo Credit: Siemens AG/P. Klingauf]

The most passionate bikers, however, want their bikes to be completely personalized. "These unique bikes cannot be beaten in terms of exclusivity. When it comes to design and technology, we make the virtually impossible possible," says junior manager Len Kodlin. In some of these models, the only thing that's left is the engine, with its unmistakable Harley-Davidson sound; the rest of the bike is made up of components that have been developed and produced entirely by Kodlin. Customers' budgets are the primary thing limiting their imagination. Enthusiasts pay up to $130,000 for these unique rides. There also are, of course, technical approval restrictions for individual countries.

Avoiding imitations

When fulfilling a customer's dream of owning a personalized motorcycle, the customizers at Kodlin Motorcycle not only adapt parts, they also manufacture many individual parts themselves. Various styles of footboards, footpegs, turn-signal trim, air filters, engine covers, hand grips, and mirror brackets are manufactured individually or in very small series.

Outsourcing production could be cheaper in many cases, but for Kodlin, this is not an option. Len Kodlin explains the reasoning behind the decision. "Unique pieces are the basis of our whole company," he says. "The risk of copies appearing is simply too great. Our customers pay for something unique, and that's what we give them. This is why we do everything ourselves, from sheet-metal work and welding to milling, turning, painting, and assembly."

Kodlin has an extremely wide range of manufacturing capabilities to prevent imitations and rival products, thus safeguarding its competitive edge. The company invests heavily in production expertise and machinery. Kodlin even has a world manufacturer identifier. This official designation signals that Kodlin is officially a manufacturer that can build and approve motorcycles.

An integrated process from the design to the machine

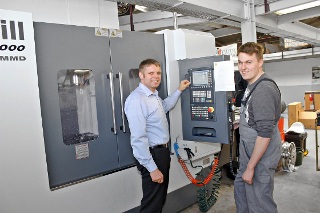

Anyone who wants to survive the competition as a small, independent customizer needs top-quality CNC machines. That's why the core of Kodlin's production process is a PreMill VL 1000 CNC machining center from MMD Werkzeugmaschinen with a Sinumerik 828D CNC system. Len Kodlin, a trained precision mechanic himself, says that what matters to him and his father is that "MMD was extremely cooperative and, with the PreMill VL 1000, gave us a machine that meets our needs perfectly. The price/performance ratio was good, and with the Sinumerik 828D control -- including the intuitive Sinumerik Operate graphical user interface -- our core requirement, namely ease-of-operation, was met to our utmost satisfaction."

The demands on the machine tool and control system are high and diverse. Many simple parts are programmed directly on the machine. For this type of application, it is important for the shop-floor programming to be as simple as it is reliable and efficient. Jan Rosenkranz, a mechanic on the Kodlin team, says, "The ShopMill menu-based navigation makes everything really quick and easy." He also appreciates the convenient set-up functions.

Len Kodlin creates the CNC programs for many self-designed components at an external CAD/CAM workstation. Shown is a decorative part made of aluminum. [Photo Credit: Siemens AG/P. Klingauf]

The production of custom parts, which often involves extremely complex contouring, is entirely different. The junior manager creates the programs for these parts separately at an external CAD/CAM workstation and then transfers them to the machine using a USB stick. This means the machine can remain in operation while the junior manager can design parts for his spectacular creations, far away from production noise, in peace and quiet. Once the blank is in place, the entire machining process itself goes very quickly. With the help of various Sinumerik CNC cycles, the workpiece and the tool are set up quickly, and machining on the PreMill VL 1000 can begin.

Len Kodlin highights the clearly organized folder structure in Sinumerik Operate, which is designed in a similar way to that found on a traditional PC. Meaningful names -- such as "Handlebar1-Customer3" -- with up to 28 characters can be assigned to the programs. This improves the ability to maintain an overview, and products that have already been made can be clearly identified and accessed again at a later date.

The entire production spectrum covered

In terms of production technology, the PreMill VL 1000 offers everything needed for bike parts. The machine gets extra points for its framework construction, which makes it very stable and easily accessible.

The part is machined using the PreMill VL 1000 CNC machining center from MMD Werkzeugmaschinen, with Sinumerik 828D CNC. A 10-kW milling spindle enables the quick and precise machining of components. [Photo Credit: Siemens AG/P. Klingauf]

The majority of the components are less than 500 mm long. However, there are exceptions, such as long fork tubes. With travel paths of X = 1,020 mm, Y = 510 mm, and Z = 560 mm, plus a 1,200-mm x 500-mm clamping table, the machine covers the spectrum comprehensively. The 10-kW milling spindle provides the power needed to machine the parts quickly and precisely, which are usually made of aluminum or steel. The changer can be equipped with up to 30 tools, and the linear guides on all three axes ensure utmost precision. According to Jens Bubenheim, a sales consultant at MMD, the PreMill VL 1000 achieves a repeat accuracy of +/- 3 µm and a positioning accuracy of +/- 5 µm, which means that the desired quality is always guaranteed.

A special feature on the Sinumerik 828D CNC scores additional points for high quality, namely the Sinumerik MDynamics technology package with integrated Advanced Surface motion control. The program sequence can be set or adjusted at any time, ensuring that the machine generates an optimal ratio of speed, accuracy, and surface quality.

Len Kodlin (on the right), co-owner of Kodlin Motorcycle, says, "Our core requirement, namely ease of operation using the Sinumerik 828D CNC and the intuitive Sinumerik Operate graphical user interface, was met to our utmost satisfaction." [Photo Credit: Siemens AG/P. Klingauf]

Take the turn signal trim, for example. In this case, production accuracy is of less significance. Corresponding settings in MDynamics and the activated Advanced Surface therefore ensure that the machine works with a focus on both surface quality and speed of production.

Luckily for us, Kodlin also has a shop in the USA. You can see their offerings at kodlinusa.com.

If you want more info on any Siemens systems, a good first contact is John Meyer, Marketing Communications Manager, Siemens Industry, Inc.; 390 Kent Avenue; Elk Grove Village, IL 60007. Give John a call at 847-640-1595 or email him at john.meyer@siemens.com.

Learn more at usa.siemens.com/cnc.

Sources: Siemens, Kodlin Motorcycle

Published July 2021

Rate this article

View our terms of use and privacy policy