|

| July 12, 2022 | Volume 18 Issue 26 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

DURApulse GS30 AC Drives from AutomationDirect

Automation-Direct has added new high-performance DURApulse GS30 drives that support several control modes including sensorless vector control, closed-loop flux vector control, and torque control in a compact package. The GS30 series expands the DURApulse family by adding internal tension control loop expanded parameter sets for greater versatility, as well as optional EtherCAT and single- or dual-port EtherNet/IP communication cards. GS30 drives support up to four independent induction motor parameter sets or control of a single AC permanent magnet motor. Sizes up to 3 hp for a 230-VAC single-phase input, 50 hp for a 230-VAC three-phase input, and 100 hp for a 460-VAC three-phase input. This series offers PID control, built-in PLC functionality, and STO capability typically found with more expensive high-performance AC drives.

Automation-Direct has added new high-performance DURApulse GS30 drives that support several control modes including sensorless vector control, closed-loop flux vector control, and torque control in a compact package. The GS30 series expands the DURApulse family by adding internal tension control loop expanded parameter sets for greater versatility, as well as optional EtherCAT and single- or dual-port EtherNet/IP communication cards. GS30 drives support up to four independent induction motor parameter sets or control of a single AC permanent magnet motor. Sizes up to 3 hp for a 230-VAC single-phase input, 50 hp for a 230-VAC three-phase input, and 100 hp for a 460-VAC three-phase input. This series offers PID control, built-in PLC functionality, and STO capability typically found with more expensive high-performance AC drives.

Learn more.

Power steering systems for warehouse and autonomous vehicles

Allied Motion has introduced the electric power steering (EPS) series for steer-by-wire warehouse vehicles, autonomous AGVs, and similar material transport vehicles. This compact system includes a fully integrated motor, gearbox, controller, and optional output pinion. It is available in three frame sizes and 16 models to cover virtually any electric steering requirement in applications from small pallet lifters to AGVs/AGCs to multi-ton reach trucks. An optional, patent-pending feature, Turning Wheel Absolute Position Control, allows the controller to know the turning wheel position without external sensors.

Allied Motion has introduced the electric power steering (EPS) series for steer-by-wire warehouse vehicles, autonomous AGVs, and similar material transport vehicles. This compact system includes a fully integrated motor, gearbox, controller, and optional output pinion. It is available in three frame sizes and 16 models to cover virtually any electric steering requirement in applications from small pallet lifters to AGVs/AGCs to multi-ton reach trucks. An optional, patent-pending feature, Turning Wheel Absolute Position Control, allows the controller to know the turning wheel position without external sensors.

Learn more.

New brushless motors maximize power density

Allied Motion Technologies has introduced the KinetiMax 95 High Power Drive (HPD), an outer-rotor brushless motor. This frameless motor is designed to maximize power density for its volume with a nominal output torque of 2 Nm at 2,300 RPM, resulting in 480 W of continuous output power. At only 37 mm axial length, this compact stator-rotor set is an ideal solution for applications such as material handling systems, AGVs, mobile robots, handheld power tools, and more.

Allied Motion Technologies has introduced the KinetiMax 95 High Power Drive (HPD), an outer-rotor brushless motor. This frameless motor is designed to maximize power density for its volume with a nominal output torque of 2 Nm at 2,300 RPM, resulting in 480 W of continuous output power. At only 37 mm axial length, this compact stator-rotor set is an ideal solution for applications such as material handling systems, AGVs, mobile robots, handheld power tools, and more.

Learn more.

Compact rod motors: Effective linear thrust generation

RDM-A Series rod motors from Akribis Systems are great for space-constrained applications requiring high motor forces and smooth linear motion. These compact motors feature a tubular design to distribute magnetic flux evenly along the circumference of the stator. They achieve continuous forces from 2.1 to 137.8 N and peak forces from 6.2 to 413.4 N. An air gap between the coil and magnet track enables non-contact axial linear movement and steady force production over the length of the stroke, and ironless construction ensures cog-free motion.

RDM-A Series rod motors from Akribis Systems are great for space-constrained applications requiring high motor forces and smooth linear motion. These compact motors feature a tubular design to distribute magnetic flux evenly along the circumference of the stator. They achieve continuous forces from 2.1 to 137.8 N and peak forces from 6.2 to 413.4 N. An air gap between the coil and magnet track enables non-contact axial linear movement and steady force production over the length of the stroke, and ironless construction ensures cog-free motion.

Learn more.

NORD's heavy-duty drive systems tackle tough industrial applications

Industrial gear units from NORD DRIVE-SYSTEMS are used for a variety of heavy-duty applications, providing high output torques and long service life with minimal maintenance. Combining high-efficiency motors and dynamic VFDs, users get high performance and smooth operation. Learn which drive systems are used for which real-world applications in industries including grain, cranes and hoists, wastewater, food and beverage, and bulk material handling. Good info here.

Industrial gear units from NORD DRIVE-SYSTEMS are used for a variety of heavy-duty applications, providing high output torques and long service life with minimal maintenance. Combining high-efficiency motors and dynamic VFDs, users get high performance and smooth operation. Learn which drive systems are used for which real-world applications in industries including grain, cranes and hoists, wastewater, food and beverage, and bulk material handling. Good info here.

Read the full article.

XYZ nanopositioning stage for scanning and positioning in photonics and microscopy

PI's P-616 XYZ Piezo Nanoposition-ing Stage, based on a parallel-kinematic design, features a single, lightweight moving platform for all three axes. It offers high precision (sub-nanometer resolution) and dynamics in a compact package. Known as the NanoCube®, it is the smallest and lightest system with capacitive feedback, providing a 100-µm linear travel range in three degrees of freedom.

PI's P-616 XYZ Piezo Nanoposition-ing Stage, based on a parallel-kinematic design, features a single, lightweight moving platform for all three axes. It offers high precision (sub-nanometer resolution) and dynamics in a compact package. Known as the NanoCube®, it is the smallest and lightest system with capacitive feedback, providing a 100-µm linear travel range in three degrees of freedom.

Learn more.

Robot with longer reach handles heavier payloads

The new RV-35/50/80FR robot series from Mitsubishi Electric Automation is ideal for handling large workpieces and heavy objects. This series has a max reach of almost 83 in. (2,100 mm) and a max payload over 175 lb (80 kg), so it's a great solution for palletizing and machine tending. These robots have a wide range of safety functions, including position and speed monitoring, and simplified installation and programming when paired with Mitsubishi Electric's MELFA Smart Plus card.

The new RV-35/50/80FR robot series from Mitsubishi Electric Automation is ideal for handling large workpieces and heavy objects. This series has a max reach of almost 83 in. (2,100 mm) and a max payload over 175 lb (80 kg), so it's a great solution for palletizing and machine tending. These robots have a wide range of safety functions, including position and speed monitoring, and simplified installation and programming when paired with Mitsubishi Electric's MELFA Smart Plus card.

Learn more.

Linear servo press solutions from Tolomatic

Improve your pressing systems with electric linear actuators from Tolomatic. While hydraulic presses are a traditional choice in many manufacturing applications, a new generation of high-force Linear Servo Press technologies is now replacing high-maintenance hydraulics. They offer significant advantages in precision, programmability, energy efficiency, reliability, and flexibility.

Improve your pressing systems with electric linear actuators from Tolomatic. While hydraulic presses are a traditional choice in many manufacturing applications, a new generation of high-force Linear Servo Press technologies is now replacing high-maintenance hydraulics. They offer significant advantages in precision, programmability, energy efficiency, reliability, and flexibility.

Learn more.

Tech Tip: What is a stepper motor linear actuator?

What is a stepper motor linear actuator (SMLA), what types are available, and what can they do for your linear motion designs? Find out in this informative Thomson video. Learn how precision lead screws can be combined with a stepper motor in a number of ways, and discover which type can benefit your linear motion applications.

What is a stepper motor linear actuator (SMLA), what types are available, and what can they do for your linear motion designs? Find out in this informative Thomson video. Learn how precision lead screws can be combined with a stepper motor in a number of ways, and discover which type can benefit your linear motion applications.

View the video.

Brakes for high-speed SCARA robots and more

Precise positioning of semi-conductor wafers during SCARA assembly operations requires instantaneous braking and holding power while minimizing heat in the system. The latest compact and slender Miki Pulley BXR-LE brake models provide the needed, perfectly controlled braking in a confined area of the system using minimal power. The braking response and holding power of this power-off engaged brake makes it ideal for this and other high-speed applications. The BXR-LE brake uses 24 VDC for a split second to overcome compression spring inertia to open the brake, then consumes only 7 VDC by utilizing the BEM power control module.

Precise positioning of semi-conductor wafers during SCARA assembly operations requires instantaneous braking and holding power while minimizing heat in the system. The latest compact and slender Miki Pulley BXR-LE brake models provide the needed, perfectly controlled braking in a confined area of the system using minimal power. The braking response and holding power of this power-off engaged brake makes it ideal for this and other high-speed applications. The BXR-LE brake uses 24 VDC for a split second to overcome compression spring inertia to open the brake, then consumes only 7 VDC by utilizing the BEM power control module.

Learn more.

Automated piece-picking solution

The MI.RA/ OnePicker is a new and fully automated intelligent piece-picking solution from Comau. The easy-to-use, AI-backed, and collaborative solution reduces upstream process times, saving time, energy, and resources for warehouse, e-commerce, and other applications while increasing overall productivity and cost efficiency. Designed to autonomously pick miscellaneous objects from the same bin, it's a smart way to eliminate unsustainable sorting activities. Comes with Comau's Racer5 six-axis cobot.

The MI.RA/ OnePicker is a new and fully automated intelligent piece-picking solution from Comau. The easy-to-use, AI-backed, and collaborative solution reduces upstream process times, saving time, energy, and resources for warehouse, e-commerce, and other applications while increasing overall productivity and cost efficiency. Designed to autonomously pick miscellaneous objects from the same bin, it's a smart way to eliminate unsustainable sorting activities. Comes with Comau's Racer5 six-axis cobot.

Learn more.

Unlock cost savings: Revolutionary GAM GPL Gearbox

The GPL planetary gearbox, when paired with your preferred servo motor, delivers a solution that can match the fit and performance of direct drive motors while offering significant cost savings. With <6 arcsec backlash, GAM says this gearbox outperforms all other zero-backlash gearboxes on the market, making it the ideal choice for your applications. Discover how one company realized significant savings by replacing multiple direct drive motors with the GPL gearbox in a modular housing.

The GPL planetary gearbox, when paired with your preferred servo motor, delivers a solution that can match the fit and performance of direct drive motors while offering significant cost savings. With <6 arcsec backlash, GAM says this gearbox outperforms all other zero-backlash gearboxes on the market, making it the ideal choice for your applications. Discover how one company realized significant savings by replacing multiple direct drive motors with the GPL gearbox in a modular housing.

Read the GAM application story.

Bosch Rexroth new linear motor modules

Fast, compact, and precise. These properties characterize the new linear motor modules (LMM) with integrated screw-free direct drive from Bosch Rexroth. The axes are available in sizes 140, 180, and 220 mm and feature a zero-backlash direct drive. They complement the existing linear motion technology portfolio as a ready-to-install solution offering excellent value for money. The linear motor modules are available in all sizes with iron-core linear motors. Standard strokes are up to 1,540 mm and forces up to 2,400 N.

Fast, compact, and precise. These properties characterize the new linear motor modules (LMM) with integrated screw-free direct drive from Bosch Rexroth. The axes are available in sizes 140, 180, and 220 mm and feature a zero-backlash direct drive. They complement the existing linear motion technology portfolio as a ready-to-install solution offering excellent value for money. The linear motor modules are available in all sizes with iron-core linear motors. Standard strokes are up to 1,540 mm and forces up to 2,400 N.

Learn all the specs and options.

OnRobot doubles payload capacity of its grippers

OnRobot's new 2FG14 and 3FG25 electrical grippers for heavy-duty, collaborative applications are now launching along with the new machine tending solution AutoPilot powered by D:PLOY, developed in collaboration with Ellison Technologies. The new three-fingered 3FG25 gripper provides users with 25 kg (55.1 lb) of payload power in a compact, all-electric, lightweight form, unlocking the potential of the latest cobots. Ideal for CNC machine tending, the 2FG14 is a lightweight parallel-finger gripper with a payload of 14 kg (30.8 lb). It doubles the payload and gripping force of OnRobot's popular 2FG7 gripper while also providing 30% more total stroke.

OnRobot's new 2FG14 and 3FG25 electrical grippers for heavy-duty, collaborative applications are now launching along with the new machine tending solution AutoPilot powered by D:PLOY, developed in collaboration with Ellison Technologies. The new three-fingered 3FG25 gripper provides users with 25 kg (55.1 lb) of payload power in a compact, all-electric, lightweight form, unlocking the potential of the latest cobots. Ideal for CNC machine tending, the 2FG14 is a lightweight parallel-finger gripper with a payload of 14 kg (30.8 lb). It doubles the payload and gripping force of OnRobot's popular 2FG7 gripper while also providing 30% more total stroke.

Learn more.

Linear guide system corrects misalignments

Bishop-Wisecarver's UtiliTrak® linear guide system includes vee rails for precision and open rails for misalignment float to provide smooth and accurate motion on inaccurate structures. Because precise parallelism is difficult to achieve, it is not uncommon for mounting surfaces to be slightly out of parallel. UtiliTrak's design compensates for mounting errors and does not require absolute parallelism for accurate operation. Genius.

Bishop-Wisecarver's UtiliTrak® linear guide system includes vee rails for precision and open rails for misalignment float to provide smooth and accurate motion on inaccurate structures. Because precise parallelism is difficult to achieve, it is not uncommon for mounting surfaces to be slightly out of parallel. UtiliTrak's design compensates for mounting errors and does not require absolute parallelism for accurate operation. Genius.

Learn more.

UCLA engineers create single-step, all-in-one 3D-printing method to make robotic materials

A team of University of California - Los Angeles (UCLA) engineers and their colleagues have developed a new design strategy and 3D-printing technique to build robots in one single step.

A study that outlined the advance, along with the construction and demonstration of an assortment of tiny robots that walk, maneuver, and jump, was published in Science.

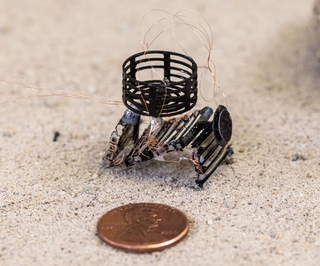

A 3D-printed "meta-bot," developed by UCLA engineers and manufactured all at once by a new type of 3D-printing process, is capable of propulsion, movement, sensing, and decision-making. [Credit: Rayne Research Group/UCLA]

The breakthrough enabled the entire mechanical and electronic systems needed to operate a robot to be manufactured all at once by a new type of 3D-printing process for engineered active materials with multiple functions (also known as metamaterials). Once 3D printed, a "meta-bot" will be capable of propulsion, movement, sensing, and decision-making.

The printed metamaterials consist of an internal network of sensory, moving, and structural elements and can move by themselves following programmed commands. With the internal network of moving and sensing already in place, the only external component needed is a small battery to power the robot.

"We envision that this design and printing methodology of smart robotic materials will help realize a class of autonomous materials that could replace the current complex assembly process for making a robot," said the study's principal investigator Xiaoyu (Rayne) Zheng, an associate professor of civil and environmental engineering, and of mechanical and aerospace engineering at the UCLA Samueli School of Engineering. "With complex motions, multiple modes of sensing, and programmable decision-making abilities all tightly integrated, it's similar to a biological system with the nerves, bones, and tendons working in tandem to execute controlled motions."

The team demonstrated the integration with an on-board battery and controller for the fully autonomous operation of the 3D-printed robots -- each the size of a finger nail. According to Zheng, who is also a member of the California NanoSystems Institute at UCLA, the methodology could lead to new designs for biomedical robots, such as self-steering endoscopes or tiny swimming robots, that can emit ultrasounds and navigate themselves near blood vessels to deliver drug doses at specific target sites inside the body.

These "meta-bots" can also explore hazardous environments. In a collapsed building, for example, a swarm of such tiny robots armed with integrated sensing parts could quickly access confined spaces, assess threat levels, and help rescue efforts by finding people trapped in the rubble.

Most robots, no matter their size, are typically built in a series of complex manufacturing steps that integrate the limbs, electronic, and active components. The process results in heavier weights, bulkier volumes, and reduced force output compared to robots that could be built using this new method.

The key in the UCLA-led, all-in-one method is the design and printing of piezoelectric metamaterials -- a class of intricate lattice materials that can change shape and move in response to an electric field or create electrical charge as a result of physical forces.

The use of active materials that can translate electricity to motions is not new. However, these materials generally have limits in their range of motion and distance of travel. They also need to be connected to gearbox-like transmission systems in order to achieve desired motions.

By contrast, the UCLA-developed robotic materials -- each the size of a penny -- are composed of intricate piezoelectric and structural elements that are designed to bend, flex, twist, rotate, expand, or contract at high speeds.

The team also presented a methodology to design these robotic materials so users could make their own models and print the materials into a robot directly.

"This allows actuating elements to be arranged precisely throughout the robot for fast, complex, and extended movements on various types of terrain," said the study's lead author Huachen Cui, a UCLA postdoctoral scholar in Zheng's Additive Manufacturing and Metamaterials Laboratory. "With the two-way piezoelectric effect, the robotic materials can also self-sense their contortions, detect obstacles via echoes and ultrasound emissions, as well as respond to external stimuli through a feedback control loop that determines how the robots move, how fast they move, and toward which target they move."

Using the technique, the team built and demonstrated three "meta-bots" with different capabilities. One robot can navigate around S-shaped corners and randomly placed obstacles, another can escape in response to a contact impact, while the third robot could walk over rough terrain and even make small jumps.

The advance incorporates 3D-printing techniques previously developed by Zheng and Hensleigh while both were researchers at Virginia Tech, which holds the patent. The researchers plan to file an additional patent through the UCLA Technology Development Group for the new methodology developed at UCLA.

Source: University of California - Los Angeles

Published July 2022

Rate this article

View our terms of use and privacy policy