|

| February 14, 2023 | Volume 19 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Amazon delivers on massive CAD conversion project for its industrial customers

The daunting task of converting millions of 2D drawings and legacy CAD files into modern 3D CAD systems leads to new opportunities and improved processes.

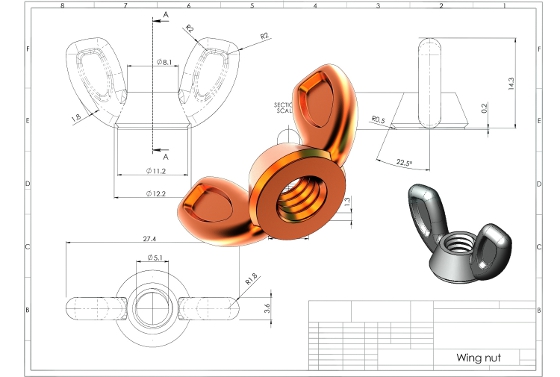

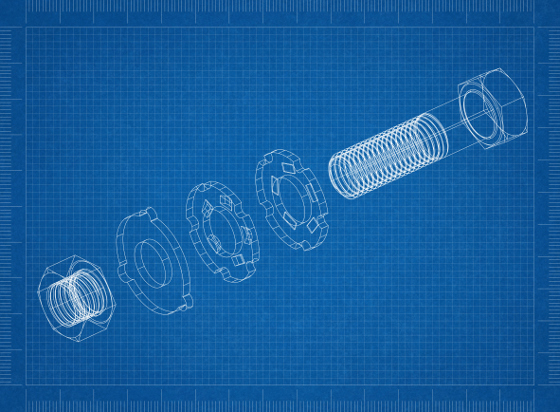

[All images courtesy: CAD/CAM Services]

Recently, Amazon's industrial products division decided to undertake what some are calling the largest CAD conversion in history. Known for being customer service-centric, the company responded to the growing demand from its industrial customers to supply downloadable CAD files for the millions of parts it supplies. This would allow engineers to then input the CAD data directly into the designs so that they could undergo digital simulations.

Converting 2D paper or scanned files into intelligent, electronic 3D Computer Aided Design (CAD) or Computer Aided Manufacturing (CAM) files, often called digital twins, is taking on an added significance as companies increasingly look to go digital. While CAD conversions are just a small piece of the overall digital transformation puzzle, the benefits make the process a point of emphasis: improved operational efficiencies, faster time to market, as well as improving new product development and throughput.

Yet, as Amazon recently encountered, the enormity of the process can often be overwhelming. Many organizations have thousands, even millions of parts, assemblies, and drawings that must be digitized into CAD-compatible files, not just scanned for preservation purposes. Even companies who have been utilizing 3D CAD software for decades often have legacy files dating as far back as DOS that can no longer be accessed and must be converted into modern CAD software systems.

Amazon's challenge

Like a lot of companies, Amazon scanned and digitized their original part blueprints and drawings. However, those 2D photos were often hard to read and not useful for most modern design and manufacturing processes.

"This was a huge job that we needed to be done quickly, and we struggled to find anyone capable of handling this type of volume on such a short timeline," says Jason Mikhailovich, senior manager at Amazon Supply, which services industrial and scientific companies.

Amazon sought advice from a major aerospace company, which suggested it look into one of the six CAD companies in the U.S. certified by the U.S. Department of Defense (DoD) for scanning and conversion work.

"We needed a company that could get ramped quickly," says Mikhailovich, who ultimately selected CAD/CAM Services, a Dallas-based CAD engineering firm with 35 years of expertise in 3D scanning, modeling, and conversions.

It did not take long before Amazon was receiving more than 1,000 CAD conversion files per day, in nine different file formats, which was required for the catalog.

"I know there are a lot of companies that are gearing up to do the same type of work, and my advice to them is to find the right partner and just take it one step at a time," adds Mikhailovich. "There is no doubt that it boosted our industrial sales, so I would say it was all worth it."

Driving force

"We are definitely seeing a huge increase in the number of CAD conversion projects we are taking on," explains Scott Shuppert, president of CAD/CAM Services. "Due to the sheer volume and complexities, most organizations are reluctant to expand their engineering departments for this type of work, so it usually gets outsourced."

Increased competition within the manufacturing sector has increased the pressure for companies to reduce costs, improve customer experience, and increase profitability. Advanced manufacturing organizations are much more reliant on CAD files that enable manufacturing automation and increased productivity.

Like Amazon, there are a number of companies that are already finding new ways to maximize their CAD conversion investment. For example, there are a growing number of websites that allow customers to upload their entire CAD file catalogs for the convenience of their customers. One such provider, TraceParts, currently offers nearly 110 million parts from over 1,400 supplier-certified product catalogs. This allows manufacturers to get in front of more potential customers without any of the leg work.

While the need to stay competitive and grow is the driving force for many of the companies that have already jumped into the CAD conversions process, for others there are more urgent concerns.

Millions of drawings are now being stored on Mylar, a type of stretched polyester film invented in the 1950s. It was originally designed as a replacement for paper because of its longer shelf life.

"The problem is that because Mylar is often improperly stored, the material tends to degrade more rapidly, impacting its accuracy and usability," explains CAD/CAM Services' Shuppert. "Converting this information into accurate and usable digital formats has become increasingly important. In fact, we just finished a huge Mylar conversion project for the U.S. Air Force."

Data chaos

Another significant advantage companies are finding is the avoidance of "CAD chaos" or a poorly organized CAD ecosystem. As an extreme example of how critical this can be, there was a well-publicized story of a major aerospace manufacturer that had to halt production of its newest aircraft after it had already reached the assembly room floor. The issue was traced back to different plants utilizing different versions of its design software. The end cost was monumental -- thousands of jobs lost, the company had reduced its profit forecasts by $6 billion, and multiple facilities were shut down.

"For us, this project dealt almost entirely with the Solidworks CAD software. However, we deal with a huge number of suppliers, and so as we move forward it's nice to know that our CAD provider also supports Catia, Siemens NX, Creo, and AutoCAD. This way we can keep our data clean and compatible," says Amazon's Mikhailovich.

Ultimately, the CAD conversion push is about revolutionizing the way products are designed, tested, manufactured, and perform over their lifecycle.

----------------

SIDEBAR: Preparing for a large CAD conversion job: Project list

With today's technology, you should be able to open edit your converted files in your native CAD system just as if you built these files internally yourself. You should not have to touch or edit the translated files.

3D projects

- Prepare a clear scope of work.

- The task is to convert X number of files from CAD system Y into CAD system Z. Typically, 3D PDF files are required to import into a company-wide electronic document and records management (EDMS) system, along with the converted CAD files to import into a CAD Vault/PLM system.

- What is your current CAD procedure workflow?

- Identify exactly what CAD system(s) the finished result should be in (i.e., Siemens NX V40, Catia V5 R21.

- Be specific and talk about your specific use requirements of Solidworks, PTC Creo, Siemens NX, and Catia -- state .sldpart/.sldasm, catpart/.catproduct as needed.

- Explain how you use this process.

- Are MBD (model-based definition) CAD files needed? Step AP242 or STL? Maybe QIF and JT?

- How feature rich do these files need to be?

- Do the converted files open and edit properly in your native CAD system?

- Does the property tree properly show up? Can you edit it?

- What company templates/set-up files should be used for this project?

- Have all files needed been identified, and do you have access to them?

- What is a realistic delivery time?

- During this process, are 2D shop drawings also needed?

- Always start with a pilot. Pick 10 to 20 files. Start with the source files, and focus on each aspect of the Scope of Work. Look at both the parts and assembly files. Bring the completed files into your CAD system(s) and PLM/PMI system. Are the surfaces editable? Are the files produced to your existing CAD standards? Are these feature rich as required. For parametric work, are the spreadsheets editable, and do they reflect a change?

- Work out any kinks as to transmitting files, naming conventions, and using correct company CAD standards. Do the files import and edit correctly?

- Does this 3D data need to be CAD Validated (like AS9102 reports?)

2D Projects

- Prepare a clear Scope of Work.

- The task is to convert about X number of files into CAD system Y, with PDF files to importing into a company-wide EDMS system, with the converted CAD files imported into a CAD Vault system.

- What is your current CAD procedure workflow?

- What exact CAD system is this going to be converted to? Paper/hard copy to AutoCAD 2020? Microstation into AutoCAD?

- Are any other formats needed such as DGN, PDF, or DXF?

- Is 2D, 3D, or both needed?

- Are third-party products required such as CADWorx (piping), AutoCAD Electrical, Civil, etc.?

- Explain how you wish to use any blocks -- cells -- families?

- Have you provided access to these?

- Do you have access to all needed data?

- Will some have to be sourced? Who is going to source this?

- Do you have a Bad Data problem? Duplicates, old outdated files, missing files, no as-builts? What is current? What should be converted? Do you need help with this part?

- Who is going to do the scanning?

- What company CAD templates should be used?

- Are all the proper attributes identified that might be needed?

- Will anything have to be mapped? (i.e., Walls that where red to Outside wall that is now blue?)

- When is this project required? Has a deliverer schedule been agreed on?

- Run a pilot. Does everything import correctly? Are items on the right layers and colors?

- Does this import into your vault system?

CAD/CAM Services has spent 34 years perfecting CAD Perfect™ CAD Conversion Services.

----------------

For more information, contact CAD/CAM Services, Inc. at 1529 Brook Lane, Celina, TX 75009; 800-938-SCAN (7226); 972-978-4288; scott@cadcam.org or cadcam.org. Please tell them you saw this article in Designfax.

Source: CAD/CAM Services

Published February 2023

Rate this article

View our terms of use and privacy policy