|

| May 09, 2023 | Volume 19 Issue 18 |

Fasteners News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

NEW! Aluminum Press-In Inserts for plastics

SPIROL is pleased to introduce a range of 2024 aluminum Press-In Inserts. Available in symmetrical (Series INS 50) and headed (INS 51) versions, the new aluminum Press-In Inserts line complements the existing brass line. Threaded Inserts are essential for reinforcing plastic components and provide a reusable thread within a bolted assembly. This ensures a proper seating torque and prevents the potential for plastic creep over time. These inserts are designed to be Pressed-In without heat and provide the lowest cost to install with acceptable joint performance for many applications.

SPIROL is pleased to introduce a range of 2024 aluminum Press-In Inserts. Available in symmetrical (Series INS 50) and headed (INS 51) versions, the new aluminum Press-In Inserts line complements the existing brass line. Threaded Inserts are essential for reinforcing plastic components and provide a reusable thread within a bolted assembly. This ensures a proper seating torque and prevents the potential for plastic creep over time. These inserts are designed to be Pressed-In without heat and provide the lowest cost to install with acceptable joint performance for many applications.

Learn more.

No-cost courses in fastener technology

Master the theory of fastener design to expand your product knowledge and become an even better and more efficient design engineer. PennEngineering's PEM FastenerClass® courses aim to give participants insight into peer and competitor techniques, a better understanding of loads and stress analysis, and enhanced career opportunities -- all beyond the basics of fastener design, selection, and installation. Self-clinch, threads, press-in inserts, surface-mount options, and sheet-to-sheet are only a few of the many topics covered.

Master the theory of fastener design to expand your product knowledge and become an even better and more efficient design engineer. PennEngineering's PEM FastenerClass® courses aim to give participants insight into peer and competitor techniques, a better understanding of loads and stress analysis, and enhanced career opportunities -- all beyond the basics of fastener design, selection, and installation. Self-clinch, threads, press-in inserts, surface-mount options, and sheet-to-sheet are only a few of the many topics covered.

See what courses are offered.

Bonding instead of soldering: MiniLEDs and microLEDs

With LED chips for backlighting units becoming smaller and smaller, DELO says adhesives are the best alternative to pick-and-place soldering for miniLED applications. Solder pastes used in serial production are increasingly reaching their limits in terms of mechanical properties and isotropic electrical conductivity. As part of a feasibility study, DELO has developed a test board to demonstrate the suitability of adhesives for miniLEDs in a flip-chip design. It proves that adhesives can create both mechanical and electrical connections in even the smallest of spaces.

With LED chips for backlighting units becoming smaller and smaller, DELO says adhesives are the best alternative to pick-and-place soldering for miniLED applications. Solder pastes used in serial production are increasingly reaching their limits in terms of mechanical properties and isotropic electrical conductivity. As part of a feasibility study, DELO has developed a test board to demonstrate the suitability of adhesives for miniLEDs in a flip-chip design. It proves that adhesives can create both mechanical and electrical connections in even the smallest of spaces.

Learn more.

Now available: Boker's new 2025 Catalog & Calendar

Boker's, Inc. has two new valuable resources available to help design engineers and procurement managers overcome engineering challenges: the 2025 Stampings & Washers Catalog and the 2025 Scheduling Calendar. The Catalog outlines the company's expansive line of more than 32,000 non-standard washer sizes, spacers, and shims that are available with no tooling charges, and the company's vast stamping capabilities. The Scheduling Calendar offers an at-a-glance, 15-month view of January 2025 through March 2026. Reverse side has a metric conversion chart.

Boker's, Inc. has two new valuable resources available to help design engineers and procurement managers overcome engineering challenges: the 2025 Stampings & Washers Catalog and the 2025 Scheduling Calendar. The Catalog outlines the company's expansive line of more than 32,000 non-standard washer sizes, spacers, and shims that are available with no tooling charges, and the company's vast stamping capabilities. The Scheduling Calendar offers an at-a-glance, 15-month view of January 2025 through March 2026. Reverse side has a metric conversion chart.

Get your catalog and calendar today.

Engineer's Guide to Low Outgassing Adhesives

Learn all about low outgassing adhesives from the masters of making things stick at Master Bond. Outgassing from adhesives can pose significant challenges -- especially in the aerospace, electronic, and optical industries. "The Engineer's Guide to Low Outgassing Adhesives" ebook covers the ASTM E595 standard, initially developed by NASA, and guides you through the adhesive selection process. No registration required.

Learn all about low outgassing adhesives from the masters of making things stick at Master Bond. Outgassing from adhesives can pose significant challenges -- especially in the aerospace, electronic, and optical industries. "The Engineer's Guide to Low Outgassing Adhesives" ebook covers the ASTM E595 standard, initially developed by NASA, and guides you through the adhesive selection process. No registration required.

Learn more.

Structural adhesive bonding 101

Learn how LORD structural adhesives are eliminating rivets, welds, and mechanical fasteners to enable lower-cost assembly. Listen to Angela Zambanini as she describes Parker LORD's acrylic, epoxy, and urethane adhesives and the best applications for each adhesive category.

Learn how LORD structural adhesives are eliminating rivets, welds, and mechanical fasteners to enable lower-cost assembly. Listen to Angela Zambanini as she describes Parker LORD's acrylic, epoxy, and urethane adhesives and the best applications for each adhesive category.

View the video.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

How Nord-Lock washers work

Can you get a design and functional edge with a wedge? In this animated video, Nord-Lock explains the principle behind their original wedge-locking technology, which secures bolted joints even when exposed to severe vibration and dynamic loads. The company says it is impossible for this washer type to loosen unintentionally, due to the wedge created underneath the bolt head and nut.

Can you get a design and functional edge with a wedge? In this animated video, Nord-Lock explains the principle behind their original wedge-locking technology, which secures bolted joints even when exposed to severe vibration and dynamic loads. The company says it is impossible for this washer type to loosen unintentionally, due to the wedge created underneath the bolt head and nut.

View the video.

NEW! Semi-automatic pin installation technology from SPIROL -- Better, faster fastening

SPIROL's new video showcases their updated Model PR and Model CR Semi-Automatic Installation Machines for Pins, Alignment Dowels, and Bushings. The video demonstrates how to operate the machine, details standard features, and optional quality and error-proofing enhancements. More than 80% of the components in this installation equipment are standard, pretested, production-proven, off-the-shelf parts. This translates into faster delivery, greater reliability, and lowest cost for equipment of comparable quality.

SPIROL's new video showcases their updated Model PR and Model CR Semi-Automatic Installation Machines for Pins, Alignment Dowels, and Bushings. The video demonstrates how to operate the machine, details standard features, and optional quality and error-proofing enhancements. More than 80% of the components in this installation equipment are standard, pretested, production-proven, off-the-shelf parts. This translates into faster delivery, greater reliability, and lowest cost for equipment of comparable quality.

View the video.

Top Product: 3M Friction Shims -- Why have more than 300 million been sold?

3M Friction Shims are small, thin steel shims with a big impact. They can increase maximum load and peak torque in bolted connections without additional fasteners or redesigns. What else makes them so popular -- and so useful?

3M Friction Shims are small, thin steel shims with a big impact. They can increase maximum load and peak torque in bolted connections without additional fasteners or redesigns. What else makes them so popular -- and so useful?

Read the full article.

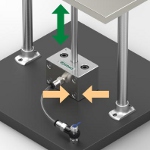

Pneumatic Shaft Locking Clamps for automated machine changeover

Discover the power of Fixtureworks' expanded line of Pneumatic Shaft-Locking Clamps. These compact pneumatic locks are perfect for secure clamping of sliding shafts and spindles after positioning and adjustment of machinery equipment. Two types available: Light Duty and Heavy Duty. Sliding shaft options include horizontal and vertical locking. Multiple shafts can be clamped at a time from a distance too.

Discover the power of Fixtureworks' expanded line of Pneumatic Shaft-Locking Clamps. These compact pneumatic locks are perfect for secure clamping of sliding shafts and spindles after positioning and adjustment of machinery equipment. Two types available: Light Duty and Heavy Duty. Sliding shaft options include horizontal and vertical locking. Multiple shafts can be clamped at a time from a distance too.

Learn more and see them in action.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

Ford Aerospace acquired by SPIROL

Engineered fasteners specialist SPIROL recently announced that Ford Aerospace Ltd based in South Shields, UK, will be joining the SPIROL group of companies.

Ford Aerospace was founded at Tyne Dock in 1910 by Robert Ford, and the family business has most recently been led by the founder's great-grandson, Chris Ford. The company specializes in manufacturing high-precision metal components and sub-assemblies for the aerospace, industrial, and high-technology sectors. It's been a leading supplier over its 113-year history dating back almost as far as the first recorded flight in 1903 by the Wright Brothers.

SPIROL is a successful, family-owned company with a rich history also closely tied to aviation development. Founded in 1948 by Herman Koehl, the grandfather of the current chief executive officer, Jeff Koehl, SPIROL has grown from a single manufacturing facility in the United States to a global enterprise with manufacturing or distribution locations on four continents and 12 countries across North America, South America, Europe, and Asia.

With a legacy spanning 75 years as an expert in fastening, joining, and assembly, SPIROL's well-established global footprint will take the UK-based Ford Aerospace's products to a wider international market. In addition, one of SPIROL's core principles is to continuously reinvest back into the business to ensure long-term, enhanced success and better serve its customers. This principle is also firmly held by Ford Aerospace, and therefore the synergies in markets, products, history, and approach to providing value to its customers ties SPIROL and Ford closely together.

Speaking about the sale, Chris Ford said, "Ford Aerospace is, and always has been, here for the people, especially our dedicated and skilled team, and it was important that any new Ford Aerospace owner share the values that have been at the heart of the company for over 100 years. Our two companies have a long history of working together, dating back to 1980 where SPIROL licensed a specialized manufacturing process from Ford Aerospace, which is still in use today. SPIROL respects Ford's strong position in the UK market and our product manufacturing knowledge. SPIROL and Ford's approach to its employees and its customers align wonderfully, and I am excited to see our strong business carry on as part of the successful SPIROL group."

Ford Aerospace's technical skills in "space compensating" management -- the production of laminated and solid shims, which ensures fast, precision tolerance compensation used on products such as fuselages, gearboxes, and movable components -- was a key offering that attracted SPIROL. These solid and laminated shims enable clients to reduce stock of individual shims and offer the option of "sizing" a particular shim by adjusting the shim pack to the desired thickness on assembly. These products simplify the assembly process while simultaneously reducing the overall cost of the assembly.

Ken Hagan, a division president at SPIROL, said, "SPIROL is an engineering, manufacturing, and sales-driven company, and as such we seek to grow and expand in our product space. Where appropriate, this includes acquiring and holding exceptional companies which fit well with our overall business, global strategy, and culture of excellence. We are excited to have Ford Aerospace join SPIROL and to be able to offer a more complete solution to our customers in Europe and beyond. We anticipate running Ford as a standalone business unit within the SPIROL group of companies. By combining the capabilities of both companies, our objective is to enhance our value-added offering to our customers both in technical expertise and products."

Learn all about SPIROL's engineered fasteners, installation machines, and parts feeding equipment at spirol.com.

Source: SPIROL

Published May 2023

Rate this article

View our terms of use and privacy policy