|

| October 17, 2023 | Volume 19 Issue 39 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy.

The ETEC Pro XL features a large build area of 249.1 x 140.1 x 165.1 mm (9.8 x 5.5 x 6.5 in.) and a significant number of new, high-value updates including:

- A 4K ultra-high-definition projector (3,840 x 2,160 pixel) that delivers optimum build size and pixel resolution;

- A premium 385-nm wavelength light engine that delivers a power density that translates into faster layer exposure times;

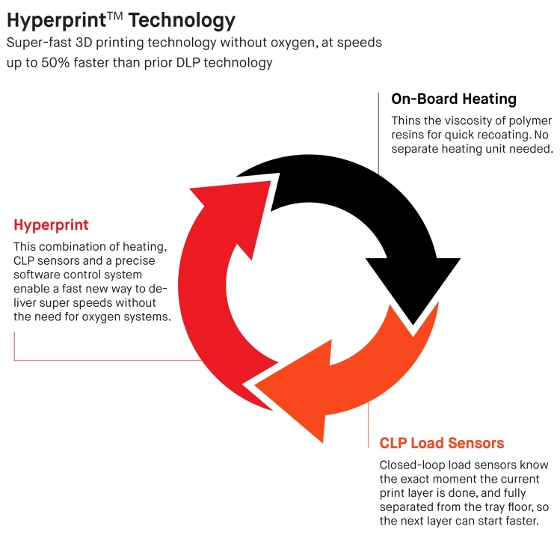

- HyperPrint™ technology that turbocharges already-fast DLP print times with a resin heater and closed-loop sensing system for continuous isotropic printing with low pulling forces; and

- Native XY resolution of 65 µm with dynamic voxel resolution in Z, material dependent, of 25, 50, or 100 µm.

"Our ETEC polymer brand has been a leader for 20+ years in high-quality DLP printing, and the ETC Pro XL continues that legacy at an accessible new price point while delivering critical user upgrades," said Ric Fulop. "DLP remains a superior polymer 3D-printing technology for speed, surface finish, and accuracy, which is why we have more than 300 Super Fleet customers around the world with more than three systems running around-the-clock production with our machines. That includes manufacturers of industrial goods, toys, jewelry, medical devices, and consumer electronics. Our average customer fleet size is six printers, but it is not uncommon for our customers to have fleets of more than 20 printers. The platform on which the ETEC Pro XL is based, originally known as the Perfactory and more recently known as the P4K, has been a major driver of these Super Fleets."

The ETEC Pro XL is currently qualified for use with E-Rigid Form Charcoal, a polyurethane-like resin with high strength and stiffness; HTM 140, a high-temperature molding material; and Easy Cast 2.0, a high-wax jewelry casting material. ETEC Pro XL is also backwards compatible with materials previously approved for prior models of the P4K and Perfactory upon request. This system is also compatible with third-party resins from trusted manufacturers such as Henkel Loctite, Evonik, and BASF.

The approved rigid, high-heat, and castable materials available on this system make it ideal for use with a variety of industrial, jewelry, and medical applications such as automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, microfluidic devices, castable jewelry patterns, short-run molds, fluid ducts, and prosthetics.

ETEC Pro XL is now available for under $40,000.

Learn more at https://etec3d.desktopmetal.com/meet-the-proxl.

Source: Desktop Metal

Published October 2023

Rate this article

View our terms of use and privacy policy