|

| February 13, 2024 | Volume 20 Issue 06 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

Why hybrid bearings are becoming the new industry standard

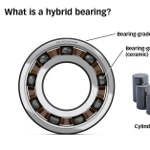

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

3M and Ansys train engineers on simulating adhesives

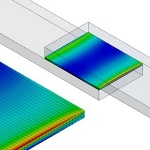

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

What can you secure with a retaining ring? 20 examples

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

See the Smalley design applications.

Load fasteners with integrated RFID

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

Learn more.

Couplings solve misalignments more precisely with targeted center designs

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

Learn more.

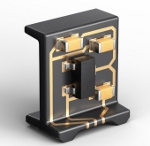

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Green steel made from toxic red mud in new economical process

The production of aluminum generates around 180 million tons of toxic red mud every year. Scientists at the Max Planck Institute for Iron Research (Dusseldorf, Germany), a center for iron research, have now shown how green steel can be produced from aluminum production waste in a relatively simple way.

In an electric arc furnace similar to those used in the steel industry for decades, they convert the iron oxide contained in the red mud into iron using hydrogen plasma. With this process, almost 700 million tons of CO2-free steel could be produced from the 4 billion tons of red mud that have accumulated worldwide to date, which corresponds to a good third of annual steel production worldwide. As the Max Planck team shows, the process would also be economically viable.

According to forecasts, demand for steel and aluminum will increase by up to 60% by 2050. However, the conventional production of these metals has a considerable impact on the environment. Eight percent of global CO2 emissions come from the steel industry, making it the sector with the highest greenhouse gas emissions. Meanwhile, the aluminum industry produces around 180 million tons of red mud every year, which is highly alkaline and contains traces of heavy metals such as chromium.

In Australia, Brazil, and China, among others, this waste is at best dried and disposed of in gigantic landfill sites, resulting in high processing costs. When it rains heavily, the red mud is often washed out of the landfill, and when it dries, the wind can blow it into the environment as dust. In addition, the highly alkaline red mud corrodes the concrete walls of the landfills, resulting in red mud leaks that have already triggered environmental disasters on several occasions, for example in China in 2012 and in Hungary in 2010. In addition, large quantities of red mud are also simply disposed of in nature.

Potential to save 1.5 billion tons of CO2 in the steel industry

"Our process could simultaneously solve the waste problem of aluminum production and improve the steel industry's carbon footprint," says Matic Jovicevic-Klug, who played a key role in the work as a scientist at the Max Planck Institute for Iron Research. In a study published in the journal Nature, the team shows how red mud can be utilized as a raw material in the steel industry. This is because the waste from aluminum production consists of up to 60% iron oxide.

The Max Planck scientists melt the red mud in an electric arc furnace and simultaneously reduce the contained iron oxide to iron using a plasma that contains 10% hydrogen. The transformation, known in technical jargon as plasma reduction, takes just 10 min., during which the liquid iron separates from the liquid oxides and can then be extracted easily. The iron is so pure that it can be processed directly into steel.

The remaining metal oxides are no longer corrosive and solidify on cooling to form a glass-like material that can be used as a filling material in the construction industry, for example. Other research groups have produced iron from red mud using a similar approach with coke, but this produces highly contaminated iron and large quantities of CO2. Using green hydrogen as a reducing agent avoids these greenhouse gas emissions.

"If green hydrogen would be used to produce iron from the four billion tons of red mud that have been generated in global aluminum production to date, the steel industry could save almost 1.5 billion tons of CO2," says Isnaldi Souza Filho, research group leader at the Max Planck Institute for Iron Research.

An economical process, including with green hydrogen and electricity

The heavy metals in the red mud can also be virtually neutralized using the process. "After reduction, we detected chromium in the iron," says Jovicevic-Klug. "Other heavy and precious metals are also likely to go into the iron or into a separate area. That's something we'll investigate in further studies. Valuable metals could then be separated and reused." Additionally, heavy metals that remain in the metal oxides are firmly bound within them and can no longer be washed out with water, as can happen with red mud.

However, producing iron from red mud directly using hydrogen not only benefits the environment twice over; it pays off economically too, as the research team demonstrated in a cost analysis. With hydrogen and an electricity mix for the electric arc furnace from only partially renewable sources, the process is worthwhile, if the red mud contains 50% iron oxide or more. If the costs for the disposal of the red mud are also considered, only 35% iron oxide is sufficient to make the process economical.

With green hydrogen and electricity, at today's costs -- also taking into account the cost of landfilling the red mud -- a proportion of 30 to 40% iron oxide is required for the resulting iron to be competitive on the market.

"These are conservative estimates, because the costs for the disposal of the red mud are probably calculated rather low," says Souza Filho. There's another advantage from a practical point of view: Electric arc furnaces are widely used in the metal industry, including in aluminum smelters, as they are used to melt down scrap metal. In many cases, the industry would therefore need to invest only a little to become more sustainable.

"It was important for us to also consider economic aspects in our study," says Dierk Raabe, director at the Max Planck Institute for Iron Research. "Now it's up to the industry to decide whether it will utilize the plasma reduction of red mud to iron."

Source: Max Planck Institute for Iron Research

Published February 2024

Rate this article

View our terms of use and privacy policy