|

| September 04, 2012 | Volume 08 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

The latest in silicone/thermoplastic parts molding

By Jim Ritzema, Rogan Corporation Engineering Manager

The practice of bonding Liquid Silicone Rubber (LSR) to rigid thermoplastic parts has traditionally consisted of molding the individual elements separately and then assembling them into a completed product using adhesives. Today, companies like Rogan Corporation, a leading manufacturer of molded plastic parts, have taken that process one huge step further - by molding Bondable Liquid Silicone Rubbers (BLSR) and thermoplastics using a two-step molding process.

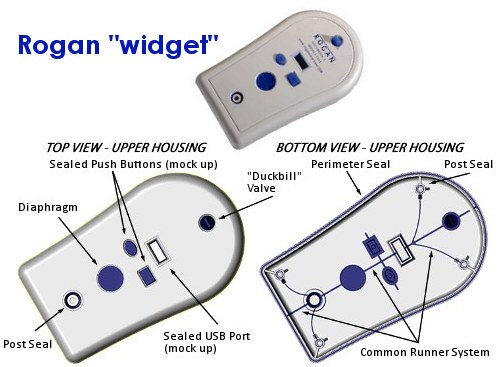

Rogan has put together its own "widget" demonstrator that shows several applications for bondable silicone. You can request your own free widget from the company by clicking here. Rogan has recently updated the widget, so now there are even more demonstration capabilities.

BLSRs can be molded to a multitude of thermoplastics, including polycarbonates, polybutylene terephthalate, Poly (p-phenylene oxide), Polyphenylene oxides, and Nylons. The process offers the benefits of both constituent elements - the pliability of BLSR and the rigidity of the thermoplastic - in a more durable, more cost-effective product than the previous technology.

BLSR/Thermoplastic molding applications

The molding process is especially suitable for medical devices, because LSR/thermoplastic parts can be sterilized and because LSR provides a watertight seal. For example, Rogan recently produced a silicone seal on a medical catheter assembly used to drain fluids from the body during and following surgery.

BLSRs can withstand temperatures up to 356 degrees F (180 degrees C) for sufficient time to meet the requirements of both steam and hot-air sterilization, making the process suitable for molding products for the medical industry. Even higher-heat-resistant BLSRs are available from suppliers if required.

The LIM (Liquid Injection Molding) of silicone results in superior waterproofing. BLSRs are able to hold tolerances of 0.0005 in. and are permanently bonded to the thermoplastic part to which they are co-molded. Separately molded and adhesively mated LSR and thermoplastic products can be subject to moisture infiltration and subsequent degradation.

This watertight capability also makes BLSR/thermoplastic parts ideal for a wide range of products used in high-moisture environments. Another recent Rogan product is a watertight door seal on a GPS/Fishfinder subject to moisture extremes.

A look inside the Liquid Injection Molding process at Rogan

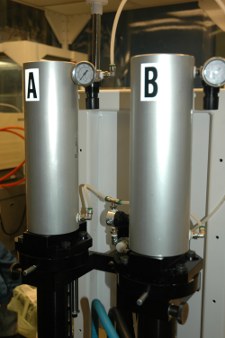

LSR molding machine in class 100,000 clean room.

Bondable liquid silicone is molded with an A and B component that cures within the mold.

Bondable liquid silicone is molded using state-of-the-art machines and controls.

Advantages of the process

This process offers numerous advantages to manufacturers of products currently using adhesive bonding to produce LSR/Thermoplastic products.

First and foremost, BLSR molding reduces the cost of labor, which results in lower production costs that can be passed on to the end-user. Faster molding cycles and the use of automated molding result in lower production costs, as well.

The operation also eliminates the potential for human assembly errors during bonding of separate parts, resulting in fewer product failures and/or recalls.

LSR availability and supply stability

LSR is a readily available material, and the majority of the raw material used in its manufacture comes from politically stable countries, including Japan and the U.S., ensuring a ready supply. Shin-Etzu alone currently sells 20 different LSR products, and increasing use will naturally lead to the development of even more products with more diverse capabilities. Increasing numbers of sophisticated LSRs are continually coming onto the market to meet the needs of more and more applications.

Reduced validation costs, design time, and time to market

In addition to significant savings in equipment and labor, using this process also results in savings in the time, effort, and cost of validating that equipment for FDA (Food and Drug Administration) approval.

The operation also frees design engineers from the necessity of designing for assembly, a process that in itself can be complex and time consuming.

Perhaps the most significant economic benefit of using this process is that it enables manufacturers of medical devices, industrial equipment, or consumer products using LSR/thermoplastic components to bring them to market more quickly, enabling them to be more competitive in the marketplace.

6 critical design considerations

Understanding the BLSR/thermoplastic molding process before beginning to design a product will help ensure the successful design and molding of that product. It is important to understand the function of the product, whether it is to be a part of a large device, a case for an electronic device, etc. What will be expected of the product? If it is a part, how will it interact with other elements in the finished device?

Once the piece itself is designed, the design for molding begins. Our experience shows that successful molding hinges upon following a number of important guidelines:

1. Thermoplastic temperature considerations

Silicone is cured in a high-heat mold. Thermoplastic materials used must be able to withstand high temperatures without distorting. Materials with minimal high-temperature distortion include (but are not limited to) polycarbonate, polyamide (nylon), polyetheretherketone (PEEK), and polyester.

It is critical to research the materials being used. The thermoplastic base part typically contains shut-off locations, and if shrinkage is miscalculated the silicone will not flow properly. Shrinkage in different thermoplastic materials can vary significantly, from 2% to 5%. Consult values supplied by the material manufacturer.

2. Avoid sharp corners

Sharp corners on the designed part affect not only material flow and mold filling, but they can also cause stress areas in the thermoplastic part and potential tear areas in the silicone during de-molding. Rounded corners are recommended.

Sharp corners may be acceptable in either the silicone or thermoplastic portion of the part at the parting line, where it actually provides a much better shutoff of material flow.

3. Maintain constant or gradual transition wall thickness

Uniform wall thickness in the molded thermoplastic will help mold filling and minimize warping and shrink marks in the finished part. Thick load-bearing sections should be replaced with ribbed supports. Uniform wall thickness enables faster fills and cycle times, which results in more consistent and reliable parts.

Silicone can sustain varying wall thicknesses and can be molded in membranes as thin as 0.015 in. But it is critical to design a part with gradual transition from one thickness to another to facilitate faster filling and quicker curing. Thick areas will increase curing time and cycle times and reduce productivity.

4. Design gating for aesthetic, processing, and function considerations

Gating should be located where it will not interfere with the function of the piece, such as at a sealing surface, but also where it speeds processing and enhances the appearance of the finished piece by avoiding sink marks. Positioning a gate in the thicker section of a thermoplastic part will avoid sink marks. It is also critical to consider the flow path of the thermoplastic material to avoid knit lines. The appearance of these lines where material flows together may be points of potential stress fracture. If knit lines are unavoidable, position them at non-load-bearing points.

An additional advantage is that the silicone may be designed to conceal the effect of a thermoplastic gate, creating a more finished look. A part with multiple silicone elements will require locating the injection site where the silicone can flow freely to each.

5. Ensure that each silicone feature can be filled

A part may include multiple silicone locations such as a soft grip, sealing areas, and membranes. Designing the thermoplastic part with recessed flow channels will ensure that material flows efficiently and cost effectively from one to another.

6. Design the part to optimize bonding

Design the part with large areas of contact between the thermoplastic and the silicone to allow for a strong bond. Where possible, design in mechanical interlocks between the materials to create both a mechanical and a chemical bond.

Following these guidelines will lead to the production of stable, fully functional LSR/thermoplastic pieces.

About the author

Jim Ritzema has been with Rogan for 30 years and has extensive experience in the areas of tooling and manufacturing, especially mold design and construction. His team provides program management and design assistance for bondable silicone projects as well as all custom molding jobs from concept to completed part.

Want more information? Click below.

Rogan Corporation

Published September 2012

Rate this article

View our terms of use and privacy policy