|

| July 09, 2013 | Volume 09 Issue 26 |

Software News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

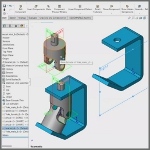

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

SOLIDWORKS 2025: Sheet metal design top features from an expert

Find out what's new in SOLIDWORKS 2025 when it comes to sheet metal and weldments, and learn some valuable tips and tricks along the way from TriMech. Topics covered include copying cut list properties, bend notches, tab and slot enhancements, groove beads (a new type of weld bead), performance enhancements, and more. When you're done, check out TriMech's full YouTube channel filled with educational material.

Find out what's new in SOLIDWORKS 2025 when it comes to sheet metal and weldments, and learn some valuable tips and tricks along the way from TriMech. Topics covered include copying cut list properties, bend notches, tab and slot enhancements, groove beads (a new type of weld bead), performance enhancements, and more. When you're done, check out TriMech's full YouTube channel filled with educational material.

View the video.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Can SOLIDWORKS run on a Mac in 2025?

According to SOLIDWORKS experts at TriMech, there's good news and bad news when it comes to the possibility of running the popular product development solution on a Mac. This video covers the possibilities and the limitations, including tweaks that may be helpful. Check out TriMech's full YouTube channel for tons of helpful tips.

According to SOLIDWORKS experts at TriMech, there's good news and bad news when it comes to the possibility of running the popular product development solution on a Mac. This video covers the possibilities and the limitations, including tweaks that may be helpful. Check out TriMech's full YouTube channel for tons of helpful tips.

View the video.

Supercar of the skies: Autodesk Alias design

Learn how Hill Helicopter is using Autodesk Alias to design the innovative HX50, the "supercar of the skies." The next-gen, private copter marries high-end automotive and aero design and materials to create a futuristic flying five-seat SUV for a discriminating clientele. A neat insider look.

Learn how Hill Helicopter is using Autodesk Alias to design the innovative HX50, the "supercar of the skies." The next-gen, private copter marries high-end automotive and aero design and materials to create a futuristic flying five-seat SUV for a discriminating clientele. A neat insider look.

View the video.

What's new in MATLAB and Simulink?

Release 2024b from MathWorks offers hundreds of new and updated features and functions in MATLAB and Simulink including several major updates -- including 5G Toolbox, Simulink Control Design, System Composer, and more -- that streamline the workflows of engineers and researchers working on wireless communications systems, control systems, and digital signal processing applications.

Release 2024b from MathWorks offers hundreds of new and updated features and functions in MATLAB and Simulink including several major updates -- including 5G Toolbox, Simulink Control Design, System Composer, and more -- that streamline the workflows of engineers and researchers working on wireless communications systems, control systems, and digital signal processing applications.

View the video.

SOLIDWORKS catch up: What's new in Assemblies?

The last couple of major releases of SOLIDWORKS each introduced significant new Assembly modeling features and workflows. Want to know what's new? Catch up on what you might have missed out on since your last upgrade -- and get a first look at highlights from the upcoming SOLIDWORKS 2025. Some very useful changes!

The last couple of major releases of SOLIDWORKS each introduced significant new Assembly modeling features and workflows. Want to know what's new? Catch up on what you might have missed out on since your last upgrade -- and get a first look at highlights from the upcoming SOLIDWORKS 2025. Some very useful changes!

View the video.

SOLIDWORKS Tips: 3 easy ways to focus on your model

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

View the video.

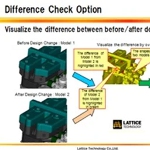

3D model sharing at Brother Industries cuts rework

When Brother Industries, maker of printers, computers, and computer-related electronics, deployed Lattice Technology's XVL Player as a viewer for sharing 3D models throughout the processes of product design, parts design, mold design, mold production, and QA of molded parts, they reduced rework significantly -- especially from downstream departments. XVL Studio with its Difference Check Option helped address the rework in mold design, for example, by always keeping everyone informed of design changes.

When Brother Industries, maker of printers, computers, and computer-related electronics, deployed Lattice Technology's XVL Player as a viewer for sharing 3D models throughout the processes of product design, parts design, mold design, mold production, and QA of molded parts, they reduced rework significantly -- especially from downstream departments. XVL Studio with its Difference Check Option helped address the rework in mold design, for example, by always keeping everyone informed of design changes.

Read this real-world case study.

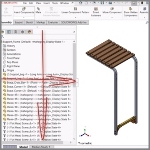

SOLIDWORKS: FeatureManager tips for assemblies

Discover tools to make your SOLIDWORKS assembly Feature-Manager design tree display easier to view and use. Learn options to limit the amount of information in each component listing, combine multiple instances of a component into a single listing, and separate fasteners mates into a new folder. Lots more tips on the SOLIDWORKS YouTube channel.

Discover tools to make your SOLIDWORKS assembly Feature-Manager design tree display easier to view and use. Learn options to limit the amount of information in each component listing, combine multiple instances of a component into a single listing, and separate fasteners mates into a new folder. Lots more tips on the SOLIDWORKS YouTube channel.

View the video.

Measurement shortcut in SOLIDWORKS

Unlock the full potential of the Measure tool in SOLIDWORKS. Franco Rotoli from SOLIDWORKS reviews how to obtain measurements for edges, faces, vertices, and more quickly -- with just a click. Users can also access edge lengths instantly and calculate angles between edges or faces effortlessly. There's a unit conversion shortcut too.

Unlock the full potential of the Measure tool in SOLIDWORKS. Franco Rotoli from SOLIDWORKS reviews how to obtain measurements for edges, faces, vertices, and more quickly -- with just a click. Users can also access edge lengths instantly and calculate angles between edges or faces effortlessly. There's a unit conversion shortcut too.

View the video.

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

Find test data issues faster: AI Anomaly Detector

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

Learn more.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

Outstanding patent recognized: Chrysler powertrain engineer wins company technology award for second time

Chrysler Powertrain Synthesis Manager Mark J. Duty was named the winner of the Walter P. Chrysler Technology Award on February 27, given to holders of Chrysler Group's most outstanding patents.

Mark J. Duty wins Walter P. Chrysler Technology Award for developing powertrain analysis tool.

Duty, a 47-year-old engineer who joined the company in 1996, earned the prize (his second) for work on the Powertrain Matching Analysis Toolset. Known within Chrysler Group as PMAT, it helps identify engine-transmission pairings that afford the most bang for the customer's buck.

The award presentation also marked the first time since 2008 that the Walter P. Chrysler Technology Award has been bestowed.

Duty, a graduate of Lake Superior State University, already has his name etched on the Walter P. Chrysler Technology Award's distinctive trophy. He shared the prize in 2007 for his work on Chrysler Group's Fuel-Saver cylinder-deactivation technology.

His latest work, PMAT, reduces the need for physical testing by employing a reverse tractive, multi-state dynamic optimization process to deliver objective performance assessments. The simulation tool also automatically optimizes powertrain and vehicle combinations.

Benefits include critical time and cost savings, key criteria considered by judges. Other criteria range from a patent's uniqueness to its impact on the customer.

PMAT helped prove Chrysler Group's ground-breaking 8-speed automatic transmission was a natural mate for the award-winning 3.6-liter Pentastar V-6. The combination helps Chrysler Group deliver best-in-class fuel economy in key segments, such as full-size pickups (Ram 1500) and full-size sedans (Chrysler 300 and Dodge Charger).

Judging for the Walter P. Chrysler Technology Award (first bestowed in 1994) is performed by a panel of more than 80 Chrysler Group subject experts, along with previous award winners. The panel reviews every Chrysler Group patent approved during the previous year and identifies a group of finalists. Senior management selects a winner.

This year, the judges reached back more than three years to pick four finalists from among 244 U.S. patents approved between 2007 and 2012. The other finalists were:

- Stephen J. Buckley and Michael Bassier for their work on collision-avoidance technology that led to the introduction of Chrysler Group's breakthrough Rear Cross Path detection system. It warns drivers of laterally approaching vehicles, a common scenario in parking lots.

- Liam J. McGuirk, Paul D. Lopez, and Arif Abbasi for their work on a cargo-management system that led to the development of the popular RamBox feature: weatherproof, lockable, drainable, illuminated storage bins located inside the walls of a pickup bed.

- Zhijian J. Wu, Michel Trumbo, Yijun Tu, and Min Han for their work on a process that predicts battery temperature while reducing system cost and complexity.

Chrysler Group gives an honorarium to all employees whose patents are approved by the U.S. Patent Office. They also receive a commemorative plaque from the company.

Winners of the Walter P. Chrysler Technology Award receive a commemorative medallion and have ribbons affixed to their plaques. Their names also are etched on a trophy displayed at Chrysler Group headquarters.

Source: Chrysler

Published March 2013

Rate this article

View our terms of use and privacy policy