|

| August 23, 2016 | Volume 12 Issue 32 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

DURApulse GS30 AC Drives from AutomationDirect

Automation-Direct has added new high-performance DURApulse GS30 drives that support several control modes including sensorless vector control, closed-loop flux vector control, and torque control in a compact package. The GS30 series expands the DURApulse family by adding internal tension control loop expanded parameter sets for greater versatility, as well as optional EtherCAT and single- or dual-port EtherNet/IP communication cards. GS30 drives support up to four independent induction motor parameter sets or control of a single AC permanent magnet motor. Sizes up to 3 hp for a 230-VAC single-phase input, 50 hp for a 230-VAC three-phase input, and 100 hp for a 460-VAC three-phase input. This series offers PID control, built-in PLC functionality, and STO capability typically found with more expensive high-performance AC drives.

Automation-Direct has added new high-performance DURApulse GS30 drives that support several control modes including sensorless vector control, closed-loop flux vector control, and torque control in a compact package. The GS30 series expands the DURApulse family by adding internal tension control loop expanded parameter sets for greater versatility, as well as optional EtherCAT and single- or dual-port EtherNet/IP communication cards. GS30 drives support up to four independent induction motor parameter sets or control of a single AC permanent magnet motor. Sizes up to 3 hp for a 230-VAC single-phase input, 50 hp for a 230-VAC three-phase input, and 100 hp for a 460-VAC three-phase input. This series offers PID control, built-in PLC functionality, and STO capability typically found with more expensive high-performance AC drives.

Learn more.

Power steering systems for warehouse and autonomous vehicles

Allied Motion has introduced the electric power steering (EPS) series for steer-by-wire warehouse vehicles, autonomous AGVs, and similar material transport vehicles. This compact system includes a fully integrated motor, gearbox, controller, and optional output pinion. It is available in three frame sizes and 16 models to cover virtually any electric steering requirement in applications from small pallet lifters to AGVs/AGCs to multi-ton reach trucks. An optional, patent-pending feature, Turning Wheel Absolute Position Control, allows the controller to know the turning wheel position without external sensors.

Allied Motion has introduced the electric power steering (EPS) series for steer-by-wire warehouse vehicles, autonomous AGVs, and similar material transport vehicles. This compact system includes a fully integrated motor, gearbox, controller, and optional output pinion. It is available in three frame sizes and 16 models to cover virtually any electric steering requirement in applications from small pallet lifters to AGVs/AGCs to multi-ton reach trucks. An optional, patent-pending feature, Turning Wheel Absolute Position Control, allows the controller to know the turning wheel position without external sensors.

Learn more.

New brushless motors maximize power density

Allied Motion Technologies has introduced the KinetiMax 95 High Power Drive (HPD), an outer-rotor brushless motor. This frameless motor is designed to maximize power density for its volume with a nominal output torque of 2 Nm at 2,300 RPM, resulting in 480 W of continuous output power. At only 37 mm axial length, this compact stator-rotor set is an ideal solution for applications such as material handling systems, AGVs, mobile robots, handheld power tools, and more.

Allied Motion Technologies has introduced the KinetiMax 95 High Power Drive (HPD), an outer-rotor brushless motor. This frameless motor is designed to maximize power density for its volume with a nominal output torque of 2 Nm at 2,300 RPM, resulting in 480 W of continuous output power. At only 37 mm axial length, this compact stator-rotor set is an ideal solution for applications such as material handling systems, AGVs, mobile robots, handheld power tools, and more.

Learn more.

Compact rod motors: Effective linear thrust generation

RDM-A Series rod motors from Akribis Systems are great for space-constrained applications requiring high motor forces and smooth linear motion. These compact motors feature a tubular design to distribute magnetic flux evenly along the circumference of the stator. They achieve continuous forces from 2.1 to 137.8 N and peak forces from 6.2 to 413.4 N. An air gap between the coil and magnet track enables non-contact axial linear movement and steady force production over the length of the stroke, and ironless construction ensures cog-free motion.

RDM-A Series rod motors from Akribis Systems are great for space-constrained applications requiring high motor forces and smooth linear motion. These compact motors feature a tubular design to distribute magnetic flux evenly along the circumference of the stator. They achieve continuous forces from 2.1 to 137.8 N and peak forces from 6.2 to 413.4 N. An air gap between the coil and magnet track enables non-contact axial linear movement and steady force production over the length of the stroke, and ironless construction ensures cog-free motion.

Learn more.

NORD's heavy-duty drive systems tackle tough industrial applications

Industrial gear units from NORD DRIVE-SYSTEMS are used for a variety of heavy-duty applications, providing high output torques and long service life with minimal maintenance. Combining high-efficiency motors and dynamic VFDs, users get high performance and smooth operation. Learn which drive systems are used for which real-world applications in industries including grain, cranes and hoists, wastewater, food and beverage, and bulk material handling. Good info here.

Industrial gear units from NORD DRIVE-SYSTEMS are used for a variety of heavy-duty applications, providing high output torques and long service life with minimal maintenance. Combining high-efficiency motors and dynamic VFDs, users get high performance and smooth operation. Learn which drive systems are used for which real-world applications in industries including grain, cranes and hoists, wastewater, food and beverage, and bulk material handling. Good info here.

Read the full article.

XYZ nanopositioning stage for scanning and positioning in photonics and microscopy

PI's P-616 XYZ Piezo Nanoposition-ing Stage, based on a parallel-kinematic design, features a single, lightweight moving platform for all three axes. It offers high precision (sub-nanometer resolution) and dynamics in a compact package. Known as the NanoCube®, it is the smallest and lightest system with capacitive feedback, providing a 100-µm linear travel range in three degrees of freedom.

PI's P-616 XYZ Piezo Nanoposition-ing Stage, based on a parallel-kinematic design, features a single, lightweight moving platform for all three axes. It offers high precision (sub-nanometer resolution) and dynamics in a compact package. Known as the NanoCube®, it is the smallest and lightest system with capacitive feedback, providing a 100-µm linear travel range in three degrees of freedom.

Learn more.

Robot with longer reach handles heavier payloads

The new RV-35/50/80FR robot series from Mitsubishi Electric Automation is ideal for handling large workpieces and heavy objects. This series has a max reach of almost 83 in. (2,100 mm) and a max payload over 175 lb (80 kg), so it's a great solution for palletizing and machine tending. These robots have a wide range of safety functions, including position and speed monitoring, and simplified installation and programming when paired with Mitsubishi Electric's MELFA Smart Plus card.

The new RV-35/50/80FR robot series from Mitsubishi Electric Automation is ideal for handling large workpieces and heavy objects. This series has a max reach of almost 83 in. (2,100 mm) and a max payload over 175 lb (80 kg), so it's a great solution for palletizing and machine tending. These robots have a wide range of safety functions, including position and speed monitoring, and simplified installation and programming when paired with Mitsubishi Electric's MELFA Smart Plus card.

Learn more.

Linear servo press solutions from Tolomatic

Improve your pressing systems with electric linear actuators from Tolomatic. While hydraulic presses are a traditional choice in many manufacturing applications, a new generation of high-force Linear Servo Press technologies is now replacing high-maintenance hydraulics. They offer significant advantages in precision, programmability, energy efficiency, reliability, and flexibility.

Improve your pressing systems with electric linear actuators from Tolomatic. While hydraulic presses are a traditional choice in many manufacturing applications, a new generation of high-force Linear Servo Press technologies is now replacing high-maintenance hydraulics. They offer significant advantages in precision, programmability, energy efficiency, reliability, and flexibility.

Learn more.

Tech Tip: What is a stepper motor linear actuator?

What is a stepper motor linear actuator (SMLA), what types are available, and what can they do for your linear motion designs? Find out in this informative Thomson video. Learn how precision lead screws can be combined with a stepper motor in a number of ways, and discover which type can benefit your linear motion applications.

What is a stepper motor linear actuator (SMLA), what types are available, and what can they do for your linear motion designs? Find out in this informative Thomson video. Learn how precision lead screws can be combined with a stepper motor in a number of ways, and discover which type can benefit your linear motion applications.

View the video.

Brakes for high-speed SCARA robots and more

Precise positioning of semi-conductor wafers during SCARA assembly operations requires instantaneous braking and holding power while minimizing heat in the system. The latest compact and slender Miki Pulley BXR-LE brake models provide the needed, perfectly controlled braking in a confined area of the system using minimal power. The braking response and holding power of this power-off engaged brake makes it ideal for this and other high-speed applications. The BXR-LE brake uses 24 VDC for a split second to overcome compression spring inertia to open the brake, then consumes only 7 VDC by utilizing the BEM power control module.

Precise positioning of semi-conductor wafers during SCARA assembly operations requires instantaneous braking and holding power while minimizing heat in the system. The latest compact and slender Miki Pulley BXR-LE brake models provide the needed, perfectly controlled braking in a confined area of the system using minimal power. The braking response and holding power of this power-off engaged brake makes it ideal for this and other high-speed applications. The BXR-LE brake uses 24 VDC for a split second to overcome compression spring inertia to open the brake, then consumes only 7 VDC by utilizing the BEM power control module.

Learn more.

Automated piece-picking solution

The MI.RA/ OnePicker is a new and fully automated intelligent piece-picking solution from Comau. The easy-to-use, AI-backed, and collaborative solution reduces upstream process times, saving time, energy, and resources for warehouse, e-commerce, and other applications while increasing overall productivity and cost efficiency. Designed to autonomously pick miscellaneous objects from the same bin, it's a smart way to eliminate unsustainable sorting activities. Comes with Comau's Racer5 six-axis cobot.

The MI.RA/ OnePicker is a new and fully automated intelligent piece-picking solution from Comau. The easy-to-use, AI-backed, and collaborative solution reduces upstream process times, saving time, energy, and resources for warehouse, e-commerce, and other applications while increasing overall productivity and cost efficiency. Designed to autonomously pick miscellaneous objects from the same bin, it's a smart way to eliminate unsustainable sorting activities. Comes with Comau's Racer5 six-axis cobot.

Learn more.

Unlock cost savings: Revolutionary GAM GPL Gearbox

The GPL planetary gearbox, when paired with your preferred servo motor, delivers a solution that can match the fit and performance of direct drive motors while offering significant cost savings. With <6 arcsec backlash, GAM says this gearbox outperforms all other zero-backlash gearboxes on the market, making it the ideal choice for your applications. Discover how one company realized significant savings by replacing multiple direct drive motors with the GPL gearbox in a modular housing.

The GPL planetary gearbox, when paired with your preferred servo motor, delivers a solution that can match the fit and performance of direct drive motors while offering significant cost savings. With <6 arcsec backlash, GAM says this gearbox outperforms all other zero-backlash gearboxes on the market, making it the ideal choice for your applications. Discover how one company realized significant savings by replacing multiple direct drive motors with the GPL gearbox in a modular housing.

Read the GAM application story.

Bosch Rexroth new linear motor modules

Fast, compact, and precise. These properties characterize the new linear motor modules (LMM) with integrated screw-free direct drive from Bosch Rexroth. The axes are available in sizes 140, 180, and 220 mm and feature a zero-backlash direct drive. They complement the existing linear motion technology portfolio as a ready-to-install solution offering excellent value for money. The linear motor modules are available in all sizes with iron-core linear motors. Standard strokes are up to 1,540 mm and forces up to 2,400 N.

Fast, compact, and precise. These properties characterize the new linear motor modules (LMM) with integrated screw-free direct drive from Bosch Rexroth. The axes are available in sizes 140, 180, and 220 mm and feature a zero-backlash direct drive. They complement the existing linear motion technology portfolio as a ready-to-install solution offering excellent value for money. The linear motor modules are available in all sizes with iron-core linear motors. Standard strokes are up to 1,540 mm and forces up to 2,400 N.

Learn all the specs and options.

OnRobot doubles payload capacity of its grippers

OnRobot's new 2FG14 and 3FG25 electrical grippers for heavy-duty, collaborative applications are now launching along with the new machine tending solution AutoPilot powered by D:PLOY, developed in collaboration with Ellison Technologies. The new three-fingered 3FG25 gripper provides users with 25 kg (55.1 lb) of payload power in a compact, all-electric, lightweight form, unlocking the potential of the latest cobots. Ideal for CNC machine tending, the 2FG14 is a lightweight parallel-finger gripper with a payload of 14 kg (30.8 lb). It doubles the payload and gripping force of OnRobot's popular 2FG7 gripper while also providing 30% more total stroke.

OnRobot's new 2FG14 and 3FG25 electrical grippers for heavy-duty, collaborative applications are now launching along with the new machine tending solution AutoPilot powered by D:PLOY, developed in collaboration with Ellison Technologies. The new three-fingered 3FG25 gripper provides users with 25 kg (55.1 lb) of payload power in a compact, all-electric, lightweight form, unlocking the potential of the latest cobots. Ideal for CNC machine tending, the 2FG14 is a lightweight parallel-finger gripper with a payload of 14 kg (30.8 lb). It doubles the payload and gripping force of OnRobot's popular 2FG7 gripper while also providing 30% more total stroke.

Learn more.

Linear guide system corrects misalignments

Bishop-Wisecarver's UtiliTrak® linear guide system includes vee rails for precision and open rails for misalignment float to provide smooth and accurate motion on inaccurate structures. Because precise parallelism is difficult to achieve, it is not uncommon for mounting surfaces to be slightly out of parallel. UtiliTrak's design compensates for mounting errors and does not require absolute parallelism for accurate operation. Genius.

Bishop-Wisecarver's UtiliTrak® linear guide system includes vee rails for precision and open rails for misalignment float to provide smooth and accurate motion on inaccurate structures. Because precise parallelism is difficult to achieve, it is not uncommon for mounting surfaces to be slightly out of parallel. UtiliTrak's design compensates for mounting errors and does not require absolute parallelism for accurate operation. Genius.

Learn more.

Chock full of exciting technology firsts, NASA's Asteroid Redirect Mission completes robotic design milestone

From moving asteroids to electric space propulsion to bringing space boulders to the moon, this project is chock full of technological daring.

NASA is developing a first-ever robotic mission to visit a large near-Earth asteroid, collect a multi-ton boulder from its surface, and redirect it into a stable orbit around the moon. Once it's there, astronauts will explore it and return with samples in the 2020s. This ambitious, multi-stage project is part of NASA's plan to advance the new technologies and spaceflight experience needed for a human mission to the Martian system in the 2030s.

In the Robotics Operation Center at NASA's Goddard Space Flight Center in Greenbelt, MD, an engineering development unit of the robotic capture system is tested at full scale. [Credits: NASA]

Following a key program review, NASA approved the Asteroid Redirect Mission (ARM) to proceed to the next phase of design and development for the mission's robotic segment. ARM is a two-part mission that will integrate robotic and crewed spacecraft operations in the proving ground of deep space to demonstrate key capabilities needed for NASA's journey to Mars.

The milestone, known as Key Decision Point-B, or KDP-B, was conducted in July and formally approved by agency management Aug. 15. It is one in a series of project lifecycle milestones that every spaceflight mission for the agency passes as it progresses toward launch. At KDP-B, NASA established the content, cost, and schedule commitments for Phase B activities.

Before beginning its trip to lunar orbit, the ARM spacecraft will demonstrate a widely supported asteroid deflection technique called a gravity tractor. The spacecraft plus the mass of the captured boulder will create a small gravitational attraction to alter the orbit of the large asteroid. [Credits: NASA]

The mission's main thrust

The robotic ARM (editor's note: "ARM" is the project acronym, not a literal robotic arm) will demonstrate advanced, high-power, high-throughput solar electric propulsion; advanced autonomous high-speed proximity operations at a low-gravity planetary body; controlled touchdown and liftoff with a multi-ton mass from a low-gravity planetary body, astronaut spacewalk activities for sample selection, extraction, containment, and return; and mission operations of integrated robotic and crewed vehicle stack -- all key components of future in-space operations for human missions to Mars.

The robotic component of the ARM mission will demonstrate the world's most advanced and most efficient solar electric propulsion system as it travels to a near-Earth asteroid (NEA). NEAs are asteroids that are fewer than 121 million miles (1.3 AU) from the sun at the closest point in their orbit. Although the target asteroid is not expected to be officially selected until 2020, NASA is using 2008 EV5 as the reference asteroid while the search continues for potential alternates.

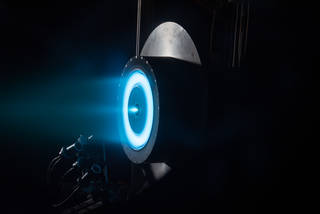

The HERMeS (Hall Effect Rocket with Magnetic Shielding) Technology Development Unit thruster exceeds over 1,300 hours of operational wear testing in a vacuum facility at the NASA Glenn Research Center in Cleveland, OH. Magnetic shielding protects the walls of the thruster from erosion, a major breakthrough in Hall thruster design that could hold the key to long-life, reusable electric propulsion systems. [Credits: NASA]

What makes a target asteroid such as 2008 EV5 particularly appealing to the scientific, exploration, and industrial communities is that it is a primitive, C-type (carbonaceous) asteroid, believed to be rich in volatiles, water, and organic compounds. The ability to extract core samples from the captured boulder will allow scientists to evaluate how its composition varies with depth and could unlock clues to the origins of our solar system. Astronaut sampling and potential commercial activities could indicate the value of C-type asteroids for commercial mining purposes, which in turn could have significant impacts on how deep space missions are designed in the future.

After collecting a multi-ton boulder from the asteroid, the robotic spacecraft will slowly redirect the boulder to an orbit around the moon, using the moon's gravity for an assist, where NASA plans to conduct a series of proving ground missions in the 2020s. There, astronauts will be able to select, extract, collect, and return samples from the multi-ton asteroid mass, and conduct other human-robotic and spacecraft operations in the proving ground that will validate concepts for NASA's journey to Mars.

In the Spacecraft Structures Lab at NASA's Langley Research Center, Asteroid Redirect Mission robotic contact and restraint system is prototyped and tested. [Credits: NASA]

Meeting objectives and setting new ones

Earlier this year, NASA updated the target launch date for the robotic mission to December 2021 in order to incorporate acquisition of the industry robotic spacecraft development into the project schedule. To reflect this new target date, the project's cost cap was increased at KDP-B from $1.25 billion to $1.4 billion. This figure does not include the launch vehicle or the post-launch operations phase. The crewed segment, targeted for launch in 2026, remains in an early mission concept phase, or pre-formulation.

During Phase B of the robotic mission, the program will develop a baseline mission design to meet requirements consistent with NASA's direction on risk, cost, and schedule, and will conduct an independent review of the baseline project design.

Completing KDP-B is a catalyst for increased external involvement in the robotic mission development, explained Michele Gates, program director for ARM at NASA Headquarters in Washington.

"Since its early formulation, NASA has invited mission concept feedback and development ideas from the planetary science community, general public, U.S., and global industry, and international partners," said Gates. "With KDP-B under our belt, ARM can now move forward to define partnerships and opportunities for long-term engagement."

The robotic ARM project, led by NASA's Jet Propulsion Laboratory (JPL) in Pasadena, CA, will issue a request for proposals for the spacecraft to a set of aerospace companies that previously worked with the ARM robotic design team on a six-month study of spacecraft concepts to meet mission requirements. KDP-B serves as authority for JPL to proceed with the next procurement phase.

NASA plans to issue a solicitation in September that will include a call for partner-provided payloads on the robotic flight system. This call is in addition to potential cooperation under discussion with the Italian Space Agency. NASA will provide spacecraft integration, power, data storage, and communication capabilities for selected payloads, which the agency will choose based on contributions to both partner goals and ARM objectives, with consideration for those that may support risk reduction for the mission.

This solicitation also will include a membership call for an ARM Investigation Team, which will be a multidisciplinary group of U.S. industry, academia, government, and international members. The Investigation Team will operate on an initial three- to five-year term, providing technical expertise to the ARM robotic and crewed project teams.

The team will conduct analyses of spacecraft and mission design, and investigate concepts to support robotic mission objectives, including overall science, planetary defense, asteroid resource use, and deep-space capability demonstrations. Led out of NASA's Langley Research Center in Hampton, VA, the Investigation Team work will continue some of the research conducted by the ARM Formulation Assessment and Support Team, which helped define mission concepts and inform mission requirements and risks over a three-month period in 2015.

Source: NASA

Published August 2016

Rate this article

View our terms of use and privacy policy