|

| July 10, 2018 | Volume 14 Issue 26 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

When glass or plastic can't cut it: Transparent ceramics solve critical design challenges

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

→ Contact Jackson Evans, Sales Engineer at INSACO jpe@insaco.com.

→ Learn more about INSACO materials and capabilities.

New aero and defense PEKK-based FDM polymers from Stratasys

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Learn more.

EOS expands its Nickel superalloys for 3D printing

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

Learn more.

CNC machining: How to avoid high costs on thin walls

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Read the full article.

Eco-friendly thermoplastic: Light, rigid, strong, damping

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Learn more.

Sound-dampening foam with an eco edge

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

Learn more.

Fastest large-format SLA 3D printer in the world

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Learn more.

Keypad teardown and design insights with Autodesk and Xometry

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Watch this Xometry webinar at your convenience.

Tube cutting and bending design guide: Xometry

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Learn more.

SPEE3D develops ultra-corrosion-resistant alloy

-- a game-changer for maritime additive manufacturing

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Read the full article.

New polymer bearings are PFAS- and PTFE-free

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

Learn more.

New high-speed PSLA 270 printer from 3D Systems

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

Learn more including materials and build sizes.

Scientists discover a link between superconductivity and the periodic table

Scientists from Moscow Institute of Physics and Technology and Skoltech have demonstrated the high-temperature superconductivity of actinium hydrides and discovered a general principle for calculating the superconductivity of hydrides based on the periodic table alone. The results of their study were published in March in The Journal of Physical Chemistry Letters.

High-temperature superconductivity is a phenomenon of zero electrical resistance in certain materials at temperatures above -196 C (the temperature of liquid nitrogen) that physicists, chemists, and materials scientists worldwide have been intensely researching for decades, as room-temperature superconductors open up vast prospects for the power industry, transport, and other technology-driven sectors.

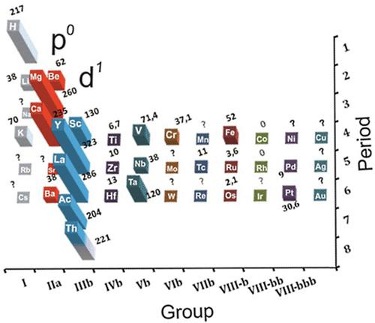

Scientists in Moscow propose that p0 and d1 metals with low-lying empty orbitals tend to form phonon-mediated high-temperature superconducting (HTSC) metal polyhydrides. The correlation to the pattern in the periodic table may help identify promising superconducting materials more quickly. [Credit: Dmitrii V. Semenok et al./The Journal of Physical Chemistry Letters]

Currently, the record holder in high-temperature superconductivity is hydrogen sulfide (H3S), which functions as a superconductor at 1.5 million atmospheres and temperatures down to -70 C. Such pressure levels can only be attained in a lab environment, not in real life, and the temperature is way below room temperature, so the search continues for new superconductors. Perhaps an even higher-temperature superconductivity can be attained in metal-hydrogen compounds. Yet the link between chemical composition and superconductivity was unclear, leaving scientists to puzzle it all out by trial and error.

A group of chemists led by Artem R. Oganov, professor at Moscow Institute of Physics and Technology and Skoltech, recently discovered that certain elements capable of forming superconducting compounds are arranged in a specific pattern in the periodic table.

They theorized that high-temperature superconductivity develops in substances containing metal atoms that come close to populating a new electronic subshell. Metal atoms inside the crystal are thought to become highly sensitive to the positions of the neighboring atoms, which results in strong electron-phonon interaction -- the underlying effect of conventional superconductivity.

Based on this assumption and looking at the periodic table, the scientists supposed that high-temperature superconductivity could occur in actinium hydrides -- substances that fit the desired subshell pattern. Their supposition was verified and confirmed: superconductivity was predicted for AcH16 at temperatures of -69 to -22 C at 1.5 million atmospheres.

"The very idea of a connection between superconductivity and the periodic table was first put forward by Dmitry Semenok, a student at my lab," said Oganov. The principle he discovered is very simple, and it is really amazing that no one had hit upon it before."

Source: Moscow Institute of Physics and Technology

Published April 2018

Rate this article

View our terms of use and privacy policy