|

| February 26, 2019 | Volume 15 Issue 08 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Durable, full redundant angle sensors for automotive and off-highway

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Novotechnik's new RSK-3200 Series angle sensors are designed for harsh automotive and off-highway applications. Measurement range is 0 to 360 degrees, and the temperature range is -40 to 125 C. This unit's built-in coupling accepts D-Shaft, with shaft customization available. The sensors are sealed to IP 67 or IP 69k depending on version. RSK-3200 Series sensors are extremely durable with MTTF of 285 years for each of the two channels! Applications include throttle control and EGR valves, transmission gear position, and accelerator position. Very competitive pricing.

Learn more.

Great design: Handle with integrated lighting/signaling

Signaling and indicator lights, switches, and buttons -- elements that hardly any machine can do without. The new JW Winco cabinet U-handle EN 6284 integrates all these functions into a single, compact element. The new U-handle is designed to enhance the operation of systems and machines. It features an integrated button and a large, colored, backlit area on the handle. These elements can be used individually or in combination, providing a versatile tool for system control and process monitoring that can be seen from across the room.

Signaling and indicator lights, switches, and buttons -- elements that hardly any machine can do without. The new JW Winco cabinet U-handle EN 6284 integrates all these functions into a single, compact element. The new U-handle is designed to enhance the operation of systems and machines. It features an integrated button and a large, colored, backlit area on the handle. These elements can be used individually or in combination, providing a versatile tool for system control and process monitoring that can be seen from across the room.

Learn more.

World's most popular 3D multisensor metrology systems get next-gen addition

Offered in two benchtop and two floor-model options to handle nearly any size part, the SmartScope M-Series systems from Optical Gaging Products usher in the next generation of enhancements in image accuracy, optics, and throughput to the world's most popular 3D multisensor video measurement platform. SmartScope M-Series features fixed optics with a 20-megapixel camera and proprietary Virtual Zoom, combined with advanced sensors, illumination, and accessories, to achieve class-leading optical measurement speeds. Lots more features.

Offered in two benchtop and two floor-model options to handle nearly any size part, the SmartScope M-Series systems from Optical Gaging Products usher in the next generation of enhancements in image accuracy, optics, and throughput to the world's most popular 3D multisensor video measurement platform. SmartScope M-Series features fixed optics with a 20-megapixel camera and proprietary Virtual Zoom, combined with advanced sensors, illumination, and accessories, to achieve class-leading optical measurement speeds. Lots more features.

Learn more.

SOLIDWORKS Tips: 3 easy ways to focus on your model

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

SOLIDWORKS Elite Applications Engineer Alin Vargatu demonstrates his top tips for focusing on your model: finding planes the easy way inside your assembly with the Q key, breadcrumbs, and a better way to use the component preview window. Very helpful. Lots more tips on the SOLIDWORKS YouTube channel.

View the video.

Push-pull transformer drivers for automotive power supplies

Nexperia's AEC-Q100 qualified, push-pull transformer drivers (NXF6501-Q100, NXF6505A-Q100, and NXF6505B-Q100) enable the design of small, low-noise, and low-EMI isolated power supplies for a range of automotive applications such as traction inverters and motor control, DC-DC converters, battery management systems, and on-board chargers in EVs. Also suitable for industrial applications such as telecommunications, medical, instrumentation, and automation equipment.

Nexperia's AEC-Q100 qualified, push-pull transformer drivers (NXF6501-Q100, NXF6505A-Q100, and NXF6505B-Q100) enable the design of small, low-noise, and low-EMI isolated power supplies for a range of automotive applications such as traction inverters and motor control, DC-DC converters, battery management systems, and on-board chargers in EVs. Also suitable for industrial applications such as telecommunications, medical, instrumentation, and automation equipment.

Learn more.

Mini linear position sensor for drones, robots, aero, more

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

H. G. Schaevitz LLC, Alliance Sensors Group is now offering a miniature, lightweight LZ SERIES linear position sensor product line utilizing LVIT Technology™. These sensors are designed for tight spaces that require excellent stroke-to-length ratio. They are contactless devices for use by drones, OEMs, aerospace, robotics, factory automation, or assembly machinery applications where precision in position sensing is crucial.

Learn all the specs.

What is a Heatric Printed Circuit Heat Exchanger?

According to Parker Hannifin, "A Printed Circuit Heat Exchanger is a robust, corrosion-resistant, high-integrity plate-type heat exchanger manufactured using diffusion bonding." Learn about the technology and why Heatric, a Parker brand, "can manufacture a unit up to 85% smaller and lighter than traditional technologies such as shell and tube heat exchangers."

According to Parker Hannifin, "A Printed Circuit Heat Exchanger is a robust, corrosion-resistant, high-integrity plate-type heat exchanger manufactured using diffusion bonding." Learn about the technology and why Heatric, a Parker brand, "can manufacture a unit up to 85% smaller and lighter than traditional technologies such as shell and tube heat exchangers."

Read this informative Parker blog.

Tech Tip: Mastering sheet metal bend calculations in Onshape

Mastering bend calculations in sheet metal design is a key skill that can impact the accuracy and manufactur-ability of your designs significantly. Explore the various options available to become a pro in this Onshape Tech Tip: K Factor, bend allowance, and bend deduction, with guidance on when each should be used. You may learn something even if you don't use this software.

Mastering bend calculations in sheet metal design is a key skill that can impact the accuracy and manufactur-ability of your designs significantly. Explore the various options available to become a pro in this Onshape Tech Tip: K Factor, bend allowance, and bend deduction, with guidance on when each should be used. You may learn something even if you don't use this software.

Read the Onshape blog.

Seifert thermoelectric enclosure coolers from AutomationDirect beat the heat

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

Raspberry Pi Pico 2: Microcontroller board with 2x flash memory

Raspberry Pi's Pico low-cost, high-performance microcontroller board with flexible digital interfaces is now being offered as a full second-generation product, complete with twice the on-board flash memory, higher performance, lower power consumption, and greater security.

Raspberry Pi's Pico low-cost, high-performance microcontroller board with flexible digital interfaces is now being offered as a full second-generation product, complete with twice the on-board flash memory, higher performance, lower power consumption, and greater security.

Read the full article.

Free-Core vs. Spring-Loaded LVDT position sensors

Linear Variable Differential Transformers are electro-mechanical devices used in many industrial applications to measure the displacement or position of an object. They convert the linear position or motion of a measured object into an electrical output that is displayed on a local readout or input into a programmable logic controller as part of an automated process control system. LVDTs come in two core configurations -- free-core and spring-loaded -- but do you know what the differences are?

Linear Variable Differential Transformers are electro-mechanical devices used in many industrial applications to measure the displacement or position of an object. They convert the linear position or motion of a measured object into an electrical output that is displayed on a local readout or input into a programmable logic controller as part of an automated process control system. LVDTs come in two core configurations -- free-core and spring-loaded -- but do you know what the differences are?

Read the full NewTek Sensor Solutions article.

New sensor listens to fuel for optimum marine diesel engine performance

Condition monitoring expert CM Technologies has added a fuel injection acoustic emission sensor to its proprietary PREMET X range of two- and four-stroke diesel engine performance indicators for marine use. The device allows engineers to monitor the acoustic signature of a diesel engine's fuel injection system to detect any problems with fuel injectors, nozzles, and pumps.

Condition monitoring expert CM Technologies has added a fuel injection acoustic emission sensor to its proprietary PREMET X range of two- and four-stroke diesel engine performance indicators for marine use. The device allows engineers to monitor the acoustic signature of a diesel engine's fuel injection system to detect any problems with fuel injectors, nozzles, and pumps.

Read the full article.

Application Note: Quadcopter propeller torque/thrust testing

The quadcopter's four propellers are designed to work in conjunction with each other to ensure there are no torque imbalances that could send the vehicle spinning out of control. But just how would a professional developer or hobbyist perform accurate propeller torque and thrust testing? Advanced sensor expert FUTEK has the answer.

The quadcopter's four propellers are designed to work in conjunction with each other to ensure there are no torque imbalances that could send the vehicle spinning out of control. But just how would a professional developer or hobbyist perform accurate propeller torque and thrust testing? Advanced sensor expert FUTEK has the answer.

Read the full article.

New enclosure heat exchanger options

Automation-Direct has added new Saginaw Enviro-Therm® air-to-air heat exchangers that use an enclosure's ambient air and either heat pipes or aluminum plate to transfer heat from inside the enclosure to the external environment. Since the ambient air is the cooling medium, the need for refrigerant is eliminated. Features include corrosion-resistant internal components, a filterless design for maximum cooling and reduced clogging, simple installation, and a programmable digital controller.

Automation-Direct has added new Saginaw Enviro-Therm® air-to-air heat exchangers that use an enclosure's ambient air and either heat pipes or aluminum plate to transfer heat from inside the enclosure to the external environment. Since the ambient air is the cooling medium, the need for refrigerant is eliminated. Features include corrosion-resistant internal components, a filterless design for maximum cooling and reduced clogging, simple installation, and a programmable digital controller.

Learn more.

World's smallest-width floating connector simplifies automotive installation

Hirose has developed a space-saving, board-to-board connector that combines floating functionality and miniature size to meet automotive specifications. The BM54 Series boasts the world's smallest-width class for its category, a 0.4-mm pitch, and a stacking height of 3.0 to 4.5 mm. This connector is ideal for PCBs with multiple connector sets and offers a wide floating range of +/- 0.4 mm in the XY direction. By absorbing board misalignment errors, floating simplifies assembly and improves assembly work efficiency. Applications include cameras, displays, millimeter wave radar, and LiDAR systems.

Hirose has developed a space-saving, board-to-board connector that combines floating functionality and miniature size to meet automotive specifications. The BM54 Series boasts the world's smallest-width class for its category, a 0.4-mm pitch, and a stacking height of 3.0 to 4.5 mm. This connector is ideal for PCBs with multiple connector sets and offers a wide floating range of +/- 0.4 mm in the XY direction. By absorbing board misalignment errors, floating simplifies assembly and improves assembly work efficiency. Applications include cameras, displays, millimeter wave radar, and LiDAR systems.

Learn more.

Firefly-inspired surfaces improve efficiency of LED lightbulbs

A new type of light-emitting diode lightbulb could one day light homes and reduce power bills, according to Penn State researchers who suggest that LEDs made with firefly-mimicking structures could improve efficiency.

"LED lightbulbs play a key role in clean energy," said Stuart (Shizhuo) Yin, professor of electrical engineering. "Overall commercial LED efficiency is currently only about 50 percent. One of the major concerns is how to improve the so-called light extraction efficiency of the LEDs. Our research focuses on how to get light out of the LED."

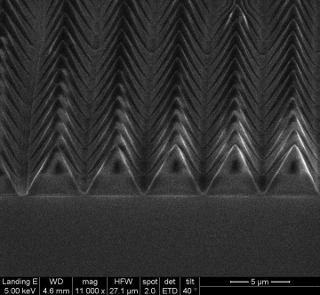

Fireflies and LEDs face similar challenges in releasing the light that they produce, because the light can reflect backwards and is lost. One solution for LEDs is to texture the surface with microstructures -- microscopic projections -- that allow more light to escape. In most LEDs these projections are symmetrical, with identical slopes on each side.

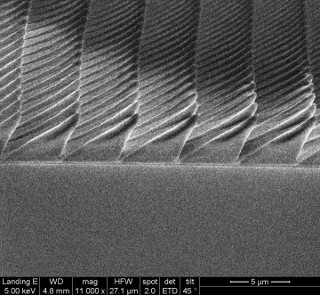

Fireflies' lanterns also have these microstructures, but the researchers noticed that the microstructures on firefly lanterns were asymmetric -- the sides slanted at different angles, giving a lopsided appearance.

Saphire surface with asymmetrical pyramids to produce more light in LEDs. [Credit: Yin Lab/Penn State]

"Later I noticed not only do fireflies have these asymmetric microstructures on their lanterns, but a kind of glowing cockroach was also reported to have similar structures on their glowing spots," said Chang-Jiang Chen, doctoral student in electrical engineering and lead author in the study. "This is where I tried to go a little deeper into the study of light extraction efficiency using asymmetric structures."

Using asymmetrical pyramids to create microstructured surfaces, the team found that they could improve light extraction efficiency to around 90 percent. The findings were recently published online in Optik and will appear in the April print edition.

Typical sapphire surface with symmetric pyramids. [Credit: Yin Lab/Penn State]

According to Yin, asymmetrical microstructures increase light extraction in two ways. First, the greater surface area of the asymmetric pyramids allows greater interaction of light with the surface, so that less light is trapped. Second, when light hits the two different slopes of the asymmetric pyramids there is a greater randomization effect of the reflections and light is given a second chance to escape.

After the researchers used computer-based simulations to show that the asymmetric surface could theoretically improve light extraction, they next demonstrated this experimentally. Using nanoscale 3D printing, the team created symmetric and asymmetric surfaces and measured the amount of light emitted. As expected, the asymmetric surface allowed more light to be released.

The LED-based lighting market is growing rapidly as the demand for clean energy increases, and it is estimated to reach $85 billion by 2024.

"Ten years ago, you go to Walmart or Lowes, LEDs are only a small portion (of their lighting stock)," said Yin. "Now, when people buy lightbulbs, most people buy LEDs."

LEDs are more environmentally friendly than traditional incandescent or fluorescent lightbulbs because they are longer lasting and more energy efficient.

Two processes contribute to the overall efficiency of LEDs. The first is the production of light -- the quantum efficiency -- which is measured by how many electrons are converted to light when energy passes through the LED material. This part has already been optimized in commercial LEDs. The second process is getting the light out of the LED -- called the light extraction efficiency.

"The remaining things we can improve in quantum efficiency are limited," said Yin. "But there is a lot of space to further improve the light extraction efficiency."

In commercial LEDs, the textured surfaces are made on sapphire wafers. First, UV light is used to create a masked pattern on the sapphire surface that provides protection against chemicals. Then when chemicals are applied, they dissolve the sapphire around the pattern, creating the pyramid array.

"You can think about it this way, if I protect a circular area and at the same time attack the entire substrate, I should get a volcano-like structure," explained Chen.

In conventional LEDs, the production process usually produces symmetrical pyramids because of the orientation of the sapphire crystals. According to Chen, the team discovered that if they cut the block of sapphire at a tilted angle, the same process would create the lopsided pyramids. The researchers altered just one part of the production process, suggesting their approach could easily be applied to commercial manufacture of LEDs.

The researchers have filed for a patent on this research.

"Once we obtain the patent, we are considering collaborating with manufacturers in the field to commercialize this technology," said Yin. Other researchers who worked on the project were Jimmy Yao, Wenbin Zhu, Ju-Hung Chao, Annan Shang, and Yun-Goo Lee, doctoral students in electrical engineering.

Source: Penn State

Published February 2019

Rate this article

View our terms of use and privacy policy