|

| June 25, 2019 | Volume 15 Issue 24 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New manufacturing process for aluminum alloys developed

A new manufacturing method eliminates multiple steps typical in conventional extrusion.

By Nick Hennen, PNNL

An advanced manufacturing process to produce nanostructured rods and tubes directly from high-performance aluminum alloy powder -- in a single step -- was recently demonstrated by researchers from the Pacific Northwest National Laboratory (PNNL).

The research team used a novel "Solid Phase Processing" approach, which eliminated several steps that are required during conventional extrusion processing of aluminum alloy powders, while also achieving a significant increase in product ductility (how far a material can stretch before it breaks).

Why does this development matter? It's good news for sectors such as the automotive industry, where the high cost of manufacturing has historically limited the use of high-strength aluminum alloys made from powders.

The team's research is described in the paper, "High Ductility Aluminum Alloy Made from Powder by Friction Extrusion," published in the June 2019 issue of Materialia.

Stepping away from conventional extrusion

High-performance aluminum alloys made from powder have long been used in lightweight components for specialized aerospace applications, where cost is not a limiting factor. However, these alloys have typically been too expensive for the automotive industry.

A typical extrusion process for aluminum alloy powders is energy and process intensive, requiring multiple steps to mass produce the material. First, the loose powder must be loaded into a can and gases removed using a vacuum, which is called "degassing." The can is then sealed, hot pressed, pre-heated, and placed into the extrusion press. After extrusion, the can is removed, or "decanned," to reveal the extruded part made from consolidated powder.

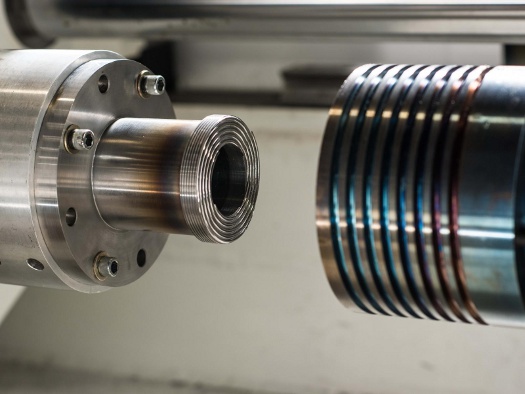

In this study, the team eliminated many of these steps, extruding nanostructured aluminum rods directly from powder in a single step, using PNNL's Shear Assisted Processing and Extrusion technology, or ShAPE™.

In the ShAPE process, a powder -- in this case, an Al-12.4TM aluminum alloy powder provided by SCM Metal Products, Inc., a division of Kymera International -- is poured into an open container. A rotating extrusion die is then forced into the powder, which generates heat at the interface between the powder and die. The material softens and easily extrudes, eliminating the need for canning, degassing, hot pressing, pre-heating, and decanning.

"This is the first published instance of an aluminum alloy powder being consolidated into nanostructured extrusions using a single-step process like ShAPE," said PNNL materials scientist Scott Whalen, who led the study.

He added, "The elimination of both the processing steps and the need for pre-heating could dramatically reduce production time as well as lower the cost and overall embedded energy within the product, which could be beneficial for automotive manufacturers who want to make passenger vehicles more affordable, lighter, and fuel efficient for the consumer."

VIDEO: PNNL's advanced manufacturing process called ShAPE can produce nanostructured rods and tubes directly from high-performance aluminum allow powder in a single step.

Besides providing the Al-12.4TM powder, SCM Metals Products performed mechanical testing to validate the resulting material's performance. PNNL and SCM Metal Products are now collaborating on a project for the Department of Energy's Office of Technology Transitions to scale up the process for larger-diameter extrusions.

Ductility -- It's a stretch

Elimination of processing steps and reduced heating weren't the only successful findings by the team.

While high-performance aluminum alloys have historically shown excellent strength, they have typically been hampered by poor ductility. However, the team found dramatic improvements in the ductility of the extrusion produced by ShAPE, measuring ductility that is two to three times that found in conventional extrusion products, and with equivalent strength.

To understand the reason for the substantial increase in ductility, transmission electron microscopy was used to evaluate the microstructures of the powder and the extruded materials. The results indicated that the ShAPE method refined the second phases in the powder -- tiny strengthening particles of non-aluminum materials. ShAPE reduces the particles to nanoscale sizes and evenly distributes them throughout the aluminum matrix, increasing ductility.

ShAPE is part of PNNL's growing suite of capabilities in Solid Phase Processing (or SPP), a disruptive approach to metals manufacturing that can be better, cheaper, and greener than melt-based methods typically associated with metals manufacturing.

The research was supported by the Materials Synthesis and Simulation Across Scales Initiative, a Laboratory Directed Research and Development project at PNNL. In addition to Kymera International, researchers from the University of California, Riverside collaborated on this project.

SIDEBAR: More benefits, other materials

In a March 19, 2019, web feature on the ShAPE process, PNNL's Mary Ann Showalter states, "... using ShAPE, nanostructured aluminum powder can be extruded directly into round bars using 50 times less force and much lower power consumption than conventional extrusion. ... The lower force and power enable substantially smaller production machinery, lowering capital expenditures and operations costs."

The method can also be used with other materials, such as magnesium.

Showalter says, "With an extrusion ratio of 200:1 demonstrated for magnesium, ShAPE achieves in a single pass what would take multiple passes with conventional extrusion. The technology enables control over grain refinement and microstructure orientation in extrusions -- which is not possible with other extrusion processes. In addition, magnesium extrusions made by ShAPE do not require costly rare earth elements to produce extrusions with sufficient ductility and energy absorption for use in some structural automotive applications (e.g., automobile bumpers), allowing more affordability in mass production."

"Early results suggest that ShAPE can be a viable method for the production of creep-resistant steels that could be used for heat exchangers in the electric power industry, and high-conductivity copper and advanced magnets for application in electric motors," Showalter says. ... "In yet another potential application, ShAPE shows promise as a method to produce semiconducting thermoelectric materials."

For more information on obtaining a license for ShAPE, contact Sara Hunt, PNNL technology commercialization manager.

Source: PNNL

Published June 2019

Rate this article

View our terms of use and privacy policy