|

| January 14, 2020 | Volume 16 Issue 02 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

When glass or plastic can't cut it: Transparent ceramics solve critical design challenges

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

Complex designs are still possible when grinding and polishing Fused Silica or Sapphire. Ceramic properties such as wear, abrasion resistance, and strength of these optical materials can be a designer's dream solution when high temperatures or severe environments rule out standard optical glass or plastic. INSACO is a machine shop specializing in ultra-hard and extreme materials.

→ Contact Jackson Evans, Sales Engineer at INSACO jpe@insaco.com.

→ Learn more about INSACO materials and capabilities.

New aero and defense PEKK-based FDM polymers from Stratasys

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Stratasys has partnered with top aerospace and defense companies to develop two newly qualified materials for 3D printing. Antero 800NA is a PEKK-based FDM polymer with excellent physical and mechanical properties for demanding applications. Antero 840CN03 is a high-performance PEKK-based FDM polymer with electrostatic dissipative (ESD) properties. These new advanced industrial solution materials were rigorously qualified in collaboration with Northrop Grumman, Boeing, Blue Origin, Raytheon, Naval Air Systems Command, the National Institute for Aviation Research, United States Air Force, BAE, and Stratasys Direct Manufacturing.

Learn more.

EOS expands its Nickel superalloys for 3D printing

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

EOS, a leading supplier of manufacturing solutions for industrial 3D printing, has added two new metal additive manufacturing materials: EOS NickelAlloy IN738 and EOS NickelAlloy K500, both delivering excellent performance, part properties, and value to a variety of industries that leverage EOS Laser Powder Bed Fusion (LBPF) 3D-printing technology. The IN738 superalloy is aimed at high-strength, high-stress energy and turbomachinery applications, while the K500 superalloy is a cost-effective, corrosion-resistant option for chemical, maritime, and space industries.

Learn more.

CNC machining: How to avoid high costs on thin walls

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Parts that are light and strong are crucial to nearly every industry. To achieve better performance without risking part failure, parts must maintain a specific wall-height-to-thickness ratio and wall-height-to-length ratio. Additionally, some geometries and supports can support thin walls to achieve a lighter component weight. Dive deeper into the cost drivers behind CNC-machined thin walls in this Xometry design-for-manufacturing article.

Read the full article.

Eco-friendly thermoplastic: Light, rigid, strong, damping

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Polyplastics has launched PLASTRON® LFT (Long Fiber-Reinforced Thermoplastic) RA627P, an eco-friendly composite of polypropylene (PP) resin and long cellulose fiber that delivers low density, high specific rigidity, high impact strength, and excellent damping for a range of applications including audio components and housings of industrial components. LFT exhibits 10% lower density than 30% short glass fiber-reinforced PP resin, roughly the same flexural modulus, and a specific rigidity that is higher.

Learn more.

Sound-dampening foam with an eco edge

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

BASF has introduced Basotect® EcoBalanced melamine foam, a material that helps to reduce the product carbon footprint (PCF) of many sound-absorption applications in the transportation, building, and construction industries. This easy, drop-in solution has an up to 50% lower PCF than the respective BASF standard grades but demonstrates the same material performance. Applications include engine covers, wall and ceiling sound absorbers, HVAC parts, and air cleaners.

Learn more.

Fastest large-format SLA 3D printer in the world

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Built on Formlabs' next-generation Low Force Display print engine, the new Form 4L SLA 3D printer delivers unmatched reliability with a 99% print success rate compared to other SLA 3D printers. These benefits, combined with a build volume nearly 5x the size of Form 4, allow Form 4L users to solve big problems and print smaller parts at high volume. Large-scale prints finished in under six hours.

Learn more.

Keypad teardown and design insights with Autodesk and Xometry

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Take a deep dive into the second revision of the macro keypad developed for Autodesk University's Factory Experience 2024 in this exclusive, on-demand webinar hosted by Xometry's Greg Paulsen and Autodesk Fusion's Jonathan Odom. This presentation features a live teardown of the keypad, showcasing how the design team addressed challenges and elevated the product. No registration required.

Watch this Xometry webinar at your convenience.

Tube cutting and bending design guide: Xometry

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Xometry's no-cost tube design guide offers design tips and tricks for laser-cut tube parts, including: minimums, tolerances, and sizes. The guide also covers important rules for mandrel tube bending, such as tolerancing, distance between bends, bend center line radius, types of bends to avoid, and more. Incredibly handy. If you need parts, Xometry can help with that too. It's easy to get a quote.

Learn more.

SPEE3D develops ultra-corrosion-resistant alloy

-- a game-changer for maritime additive manufacturing

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that are compatible with its Cold Spray Additive Manufacturing technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy, as it will help with supply chain delays and keep critical maritime systems operational.

Read the full article.

New polymer bearings are PFAS- and PTFE-free

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

igus has developed a new polymer bearing material called iglide JPF that is free of both per- and polyfluoroalkyl substances (PFAS) and polytetrafluoroethylene (PTFE). This innovation marks an important step in the company's efforts to create sustainable alternatives to conventional plain bearings. JPF is a dry-running, wear-resistant polymer that offers comparable friction and wear performance to iglide J. It delivers high wear resistance and durability.

Learn more.

New high-speed PSLA 270 printer from 3D Systems

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

The all-new PSLA 270 projector-based polymer 3D-printing platform and associated new materials from 3D Systems enable faster production times for a wide range of applications. This machine's high throughput and accuracy make it ideal for industries like healthcare, aerospace, automotive, and manufacturing, where precise and durable components are critical. Complementary Wash and Cure systems streamline post-processing and ensure high-quality finished parts.

Learn more including materials and build sizes.

Engineers put Leonardo da Vinci's bridge design to the test -- would have been world's longest at the time

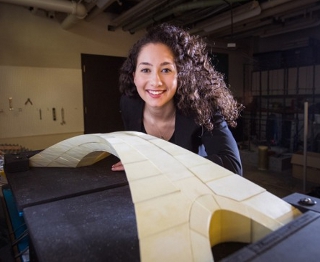

Recent MIT graduate student Karly Bast shows off the scale model of a bridge designed by Leonardo da Vinci that she and her co-workers used to prove the design's feasibility. If it were built 500 years ago, the bridge would have been the longest in the world. [Image: Gretchen Ertl]

By David L. Chandler, MIT

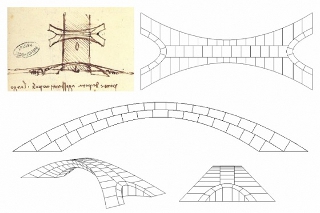

In 1502 A.D., Sultan Bayezid II sent out the Renaissance equivalent of a government RFP (request for proposals) seeking a design for a bridge to connect Istanbul with its neighbor city Galata. Leonardo da Vinci, already a well-known artist and inventor, came up with a novel bridge design that he described in a letter to the Sultan and sketched in a small drawing in his notebook.

He didn't get the job.

But 500 years after his death, the design for what would have been the world's longest bridge span of its time intrigued researchers at MIT, who wondered how thought-through Leonardo's concept was and whether it really would have worked.

Spoiler alert: Leonardo knew what he was doing.

To study the question, recent graduate student Karly Bast MEng '19, working with professor of architecture and of civil and environmental engineering John Ochsendorf and undergraduate Michelle Xie, tackled the problem by analyzing the available documents, the possible materials and construction methods that were available at the time, and the geological conditions at the proposed site, which was a river estuary called the Golden Horn. Ultimately, the team built a detailed scale model to test the structure's ability to stand and support weight, and even to withstand settlement of its foundations.

The results of the study were presented in Barcelona in October at the conference of the International Association for Shell and Spatial Structures. They will also be featured in an episode of the PBS program NOVA, set to air Nov. 13.

A flattened arch

In Leonardo's time, most masonry bridge supports were made in the form of conventional semicircular arches, which would have required 10 or more piers along the span to support such a long bridge. Leonardo's bridge concept was dramatically different -- a flattened arch that would be tall enough to allow a sailboat to pass underneath with its mast in place, as illustrated in his sketch, but that would cross the wide span with a single enormous arch.

The bridge would have been about 280 m long (though Leonardo himself was using a different measurement system, since the metric system was still a few centuries off), making it the longest span in the world at that time, had it been built. "It's incredibly ambitious," Bast says. "It was about 10 times longer than typical bridges of that time."

The design also featured an unusual way of stabilizing the span against lateral motions -- something that has resulted in the collapse of many bridges over the centuries. To combat that, Leonardo proposed abutments that splayed outward on either side, like a standing subway rider widening her stance to balance in a swaying car.

Leonardo da Vinci's original drawing of the bridge proposal (top left), showing a bird's eye view at top and a side view below, including a sailboat passing under the bridge. To the right and below that are drawings by Karly Bast and Michelle Xie showing how the structure could be divided up into 126 individual blocks, which were 3D printed to build a scale model. [Image: Karly Bast and Michelle Xie]

In his notebooks and letter to the Sultan, Leonardo provided no details about the materials that would be used or the method of construction. Bast and the team analyzed the materials available at the time and concluded that the bridge could only have been made of stone, because wood or brick could not have carried the loads of such a long span. And they concluded that, as in classical masonry bridges such as those built by the Romans, the bridge would stand on its own under the force of gravity, without any fasteners or mortar to hold the stone together.

To prove that, they had to build a model and demonstrate its stability. That required figuring out how to slice up the complex shape into individual blocks that could be assembled into the final structure. While the full-scale bridge would have been made up of thousands of stone blocks, they decided on a design with 126 blocks for their model, which was built at a scale of 1 to 500 (making it about 32 in. long). Then the individual blocks were made on a 3D printer, taking about six hours per block to produce.

"It was time consuming, but 3D printing allowed us to accurately recreate this very complex geometry," Bast says.

Testing the design's feasibility

This is not the first attempt to reproduce Leonardo's basic bridge design in physical form. Others, including a pedestrian bridge in Norway, have been inspired by his design, but in that case modern materials -- steel and concrete -- were used, so that construction provided no information about the practicality of Leonardo's engineering.

"That was not a test to see if his design would work with the technology from his time," Bast says. But because of the nature of gravity-supported masonry, the faithful scale model, albeit made of a different material, would provide such a test.

"It's all held together by compression only," she says. "We wanted to really show that the forces are all being transferred within the structure," which is key to ensuring that the bridge would stand solidly and not topple.

As with actual masonry arch bridge construction, the "stones" were supported by a scaffolding structure as they were assembled, and only after they were all in place could the scaffolding be removed to allow the structure to support itself. Then it came time to insert the final piece in the structure, the keystone at the very top of the arch.

"When we put it in, we had to squeeze it in. That was the critical moment when we first put the bridge together. I had a lot of doubts" as to whether it would all work, Bast recalls. But "when I put the keystone in, I thought, ‘this is going to work.' And after that, we took the scaffolding out, and it stood up."

"It's the power of geometry" that makes it work, she says. "This is a strong concept. It was well thought out." Score another victory for Leonardo.

"Was this sketch just freehanded, something he did in 50 seconds, or is it something he really sat down and thought deeply about? It's difficult to know" from the available historical material, she says. But proving the effectiveness of the design suggests that Leonardo really did work it out carefully and thoughtfully, she says. "He knew how the physical world works."

He also apparently understood that the region was prone to earthquakes, and incorporated features such as the spread footings that would provide extra stability. To test the structure's resilience, Bast and Xie built the bridge on two movable platforms and then moved one away from the other to simulate the foundation movements that might result from weak soil. The bridge showed resilience to the horizontal movement, only deforming slightly until being stretched to the point of complete collapse.

The design may not have practical implications for modern bridge designers, Bast says, since today's materials and methods provide many more options for lighter, stronger designs. But the proof of the feasibility of this design sheds more light on what ambitious construction projects might have been possible using only the materials and methods of the early Renaissance. And it once again underscores the brilliance of one of the world's most prolific inventors.

It also demonstrates, Bast says, that "you don't necessarily need fancy technology to come up with the best ideas."

Published November 2019

Rate this article

View our terms of use and privacy policy