|

| March 24, 2020 | Volume 16 Issue 12 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Versatile Transport System: Turbocharge conveyance

THK's Versatile Transport System is a high-mix production solution that will keep your production line moving. Its linear motor drive enables high-speed operations, and processing can be performed directly on top of the system's freely recirculating sliders. This highly precise, modular system has many unique features, including easily adjustable stop positions, flex layouts with path splitting and parallelization, and easy addition/subtraction of extension pieces.

THK's Versatile Transport System is a high-mix production solution that will keep your production line moving. Its linear motor drive enables high-speed operations, and processing can be performed directly on top of the system's freely recirculating sliders. This highly precise, modular system has many unique features, including easily adjustable stop positions, flex layouts with path splitting and parallelization, and easy addition/subtraction of extension pieces.

View the video.

Tech Tip: How to keep heavy loads balanced

Some Thomson smart linear actuators have a position-based synchro-nization option to help manage unbalanced loads when using multiple units. The system adjusts the speed of each actuator to keep them starting, moving, and stopping synchronously, regardless of their respective load distribution. So useful. So smart.

Some Thomson smart linear actuators have a position-based synchro-nization option to help manage unbalanced loads when using multiple units. The system adjusts the speed of each actuator to keep them starting, moving, and stopping synchronously, regardless of their respective load distribution. So useful. So smart.

Learn all about this feature.

Micropositioning stages ensure high accuracy

PI now offers fast delivery of the L-511 linear microposi-tioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm and drive forces up to 22 lb. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages for enhanced flexibility. Features high-load recirculating ball bearings for exceptional durability, even under demanding, repetitive cycles. To enhance positioning accuracy and automation throughput, this stage integrates non-contact, direction-sensing optical reference point switches located at mid-travel.

PI now offers fast delivery of the L-511 linear microposi-tioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm and drive forces up to 22 lb. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages for enhanced flexibility. Features high-load recirculating ball bearings for exceptional durability, even under demanding, repetitive cycles. To enhance positioning accuracy and automation throughput, this stage integrates non-contact, direction-sensing optical reference point switches located at mid-travel.

Learn more.

Robots think and act on the fly at moving assembly line speeds

Inbolt and FANUC are launching a manufacturing breakthrough enabling FANUC robots to tackle one of the most complex automation challenges: performing production tasks on continuously moving parts at line speeds. With Inbolt's AI-powered 3D vision, manufacturers can now automate screw insertion, bolt rundown, glue application, and other high-precision tasks on parts moving down the line without costly infrastructure investments or cycle time compromises.

Inbolt and FANUC are launching a manufacturing breakthrough enabling FANUC robots to tackle one of the most complex automation challenges: performing production tasks on continuously moving parts at line speeds. With Inbolt's AI-powered 3D vision, manufacturers can now automate screw insertion, bolt rundown, glue application, and other high-precision tasks on parts moving down the line without costly infrastructure investments or cycle time compromises.

Learn more.

Best high-speed rotary bearing in THK history

THK has developed its best-performing, high-speed rotary bearing ever: the High-Speed, Double-Row Angular Contact Ring BWH. This rotary bearing has balls aligned inside a cage between the inner and outer rings and is part of the THK Rotary Series, along with the cross-roller ring. The main features of this product are its ability to receive loads in all directions as well as its high rigidity and rotational accuracy, which are equal to that of cross-roller rings. By adopting a new structure to change the rolling elements from rollers to balls, this product achieves the greatest high-speed performance ever offered by THK.

THK has developed its best-performing, high-speed rotary bearing ever: the High-Speed, Double-Row Angular Contact Ring BWH. This rotary bearing has balls aligned inside a cage between the inner and outer rings and is part of the THK Rotary Series, along with the cross-roller ring. The main features of this product are its ability to receive loads in all directions as well as its high rigidity and rotational accuracy, which are equal to that of cross-roller rings. By adopting a new structure to change the rolling elements from rollers to balls, this product achieves the greatest high-speed performance ever offered by THK.

Learn more.

Elevating tables: Precise vertical positioning in tight spaces

As semicon-ductors and optical components become smaller and more sophisticated, the TZ Series of precision elevating tables from IKO International provides exceptional vertical positioning accuracy in a compact size. This unit features a unique wedge mechanism guided in the vertical direction by a pair of IKO C-Lube Super MX linear motion rolling guides arranged in parallel to achieve highly precise positioning with exceptional rigidity. An optional linear encoder provides full closed loop control to achieve positioning accuracy as high as 0.005 mm, with repeatability of +/-0.001 mm.

As semicon-ductors and optical components become smaller and more sophisticated, the TZ Series of precision elevating tables from IKO International provides exceptional vertical positioning accuracy in a compact size. This unit features a unique wedge mechanism guided in the vertical direction by a pair of IKO C-Lube Super MX linear motion rolling guides arranged in parallel to achieve highly precise positioning with exceptional rigidity. An optional linear encoder provides full closed loop control to achieve positioning accuracy as high as 0.005 mm, with repeatability of +/-0.001 mm.

Learn more and get all the specs.

This cobot is all about safety around people

The COBOTTA PRO from DENSO Robotics is a lightweight, high-speed collaborative robot designed for communication between workers and robots while maximizing productivity. It delivers a blend of productivity and safety for both simple tasks and multi-step processes like assembly and inspection work. The 6-axis unit operates at speeds up to 2,500 mm per sec when no workers are near and slows or stops when people approach. Two models available: PRO 900 (max payload 6 kg) and PRO 1300 (max payload 12 kg). Many more functions and features.

The COBOTTA PRO from DENSO Robotics is a lightweight, high-speed collaborative robot designed for communication between workers and robots while maximizing productivity. It delivers a blend of productivity and safety for both simple tasks and multi-step processes like assembly and inspection work. The 6-axis unit operates at speeds up to 2,500 mm per sec when no workers are near and slows or stops when people approach. Two models available: PRO 900 (max payload 6 kg) and PRO 1300 (max payload 12 kg). Many more functions and features.

Learn more.

Powerful, pull-type clapper solenoids handle myriad jobs

New powerful, low-profile, pull-type clapper solenoids are available from Magnetic Sensor Systems (MSS). Applications include valve control, locks, starters, ventilators, clamping, sorting, appliances, tools, HVAC, brakes, clutches, switches, mixing, fire suppression systems, door controls, detent latches, and more. The S-16-264 Series of 17 Pull-Type Clapper Solenoids have ampere turns (windings) adjusted to meet the specific force and duty cycle requirements of your application. They provide up to 130 lb (578 N) of force.

New powerful, low-profile, pull-type clapper solenoids are available from Magnetic Sensor Systems (MSS). Applications include valve control, locks, starters, ventilators, clamping, sorting, appliances, tools, HVAC, brakes, clutches, switches, mixing, fire suppression systems, door controls, detent latches, and more. The S-16-264 Series of 17 Pull-Type Clapper Solenoids have ampere turns (windings) adjusted to meet the specific force and duty cycle requirements of your application. They provide up to 130 lb (578 N) of force.

Get all the specs for these solenoids and other options.

Tech Tip: Belt, screw, or chain-driven actuator?

Bishop-Wisecarver provides a quick, very useful guide to help you evaluate the right drive strategy for your system: belt, screw, or chain-driven actuator. Each drive type has unique advantages and limitations, so evaluating all your options will help you find the most suitable actuator setup for your specific application needs.

Bishop-Wisecarver provides a quick, very useful guide to help you evaluate the right drive strategy for your system: belt, screw, or chain-driven actuator. Each drive type has unique advantages and limitations, so evaluating all your options will help you find the most suitable actuator setup for your specific application needs.

Read the Bishop-Wisecarver blog.

Ultra-precise linear stage -- down to 0.005 microns

PI, a global leader in precision motion control and nanoposi-tioning, now offers fast delivery of the L-511 linear micropositioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm, drive forces up to 22 lb, and multi-axis configuration options. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages. A variety of drive and encoder options (stepper and servo motors, rotary, and linear encoders) enable ultra-fine sensitivity. Applications include: metrology, laser processing, semiconductors, biotech, optical alignment, and advanced automation.

PI, a global leader in precision motion control and nanoposi-tioning, now offers fast delivery of the L-511 linear micropositioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm, drive forces up to 22 lb, and multi-axis configuration options. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages. A variety of drive and encoder options (stepper and servo motors, rotary, and linear encoders) enable ultra-fine sensitivity. Applications include: metrology, laser processing, semiconductors, biotech, optical alignment, and advanced automation.

Learn more and get all the specs.

Choosing the right stepper motor: PM or hybrid?

According to the experts at Lin Engineering, there are two primary types of stepper motors to consider: permanent magnet (PM) and hybrid. But which is right for your application? Both types have their advantages and disadvantages, and the choice ultimately depends on your specific requirements.

According to the experts at Lin Engineering, there are two primary types of stepper motors to consider: permanent magnet (PM) and hybrid. But which is right for your application? Both types have their advantages and disadvantages, and the choice ultimately depends on your specific requirements.

Read this informative Lin Engineering article.

New PTFE-free linear guide for precise positioning

The new drylin WWP linear guide from igus features a PTFE-free locking carriage. Engineered from lubrication-free, high-performance polymers and aluminum, the guide offers a lightweight, hygienic, and low-maintenance alternative to complex mechanical and electronic adjustment systems. It is significantly more compact and lightweight than conventional recirculating ball-bearing systems. Applications include interior components in vehicles, aircraft, and furniture.

The new drylin WWP linear guide from igus features a PTFE-free locking carriage. Engineered from lubrication-free, high-performance polymers and aluminum, the guide offers a lightweight, hygienic, and low-maintenance alternative to complex mechanical and electronic adjustment systems. It is significantly more compact and lightweight than conventional recirculating ball-bearing systems. Applications include interior components in vehicles, aircraft, and furniture.

Learn more and get all the specs.

Heavy-duty gear units for mixing and agitating systems

MAXXDRIVE industrial gear units from NORD DRIVE-SYSTEMS are an established drive solution for heavy-duty applications. In addition to conveying, lifting, and driving, they also play an important role in mixing and agitating systems. MAXXDRIVE units feature a compact, one-piece UNICASE housing that delivers long service life, easy maintenance, and quiet operation. Their robust design handles high axial and radial loads, achieves output torques up to 2,495,900 lb-in., and powers up to 8,075 hp.

MAXXDRIVE industrial gear units from NORD DRIVE-SYSTEMS are an established drive solution for heavy-duty applications. In addition to conveying, lifting, and driving, they also play an important role in mixing and agitating systems. MAXXDRIVE units feature a compact, one-piece UNICASE housing that delivers long service life, easy maintenance, and quiet operation. Their robust design handles high axial and radial loads, achieves output torques up to 2,495,900 lb-in., and powers up to 8,075 hp.

Learn more.

What are non-captive linear actuators?

According to PBC Linear, their new non-captive linear actuators are different from the more common external versions of lead screw-driven linear actuators because they allow the lead screw to completely pass through the motor. This fundamental difference offers advantages for designs that have limited space available or for engineers looking to shrink the overall size of their design package.

According to PBC Linear, their new non-captive linear actuators are different from the more common external versions of lead screw-driven linear actuators because they allow the lead screw to completely pass through the motor. This fundamental difference offers advantages for designs that have limited space available or for engineers looking to shrink the overall size of their design package.

Read the full PBC Linear blog.

Güdel introduces Swiss-quality tracks for cobots

Güdel Inc. is highlighting new technologies at Automate 2025 booth #2418 that demonstrate its unmatched ability to solve automation engineering challenges. One is the Cobomover, a 7th-axis linear track purpose-built for collaborative and lightweight robots. Designed and manufactured in Switzerland, this unit extends the working range of robots up to 5 m, allowing them to operate multiple workstations and perform a variety of tasks without manual repositioning. Compatible with over 60 cobots and small traditional robots.

Güdel Inc. is highlighting new technologies at Automate 2025 booth #2418 that demonstrate its unmatched ability to solve automation engineering challenges. One is the Cobomover, a 7th-axis linear track purpose-built for collaborative and lightweight robots. Designed and manufactured in Switzerland, this unit extends the working range of robots up to 5 m, allowing them to operate multiple workstations and perform a variety of tasks without manual repositioning. Compatible with over 60 cobots and small traditional robots.

Learn more and get all the specs.

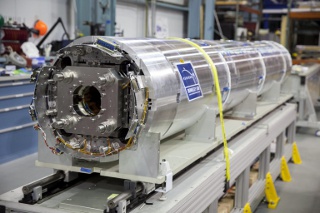

Three national labs achieve record magnetic field for accelerator focusing magnet

This new magnet -- about as long as a semitruck trailer and weighing 9 tons -- was built by teams at Berkeley Lab, Fermilab, and Brookhaven Lab for the High-Luminosity LHC upgrade project. [Credit: Marilyn Sargent/Berkeley Lab]

In a multiyear effort involving three U.S. national laboratories, researchers have successfully built and tested a powerful new focusing magnet that represents a new use for niobium-tin, a superconducting material.

The 9-ton device, about as long as a semitruck trailer, set a record for the highest field strength ever recorded for an accelerator focusing magnet: 14.1 teslas. It raises the standard for magnets operating in high-energy particle colliders.

The U.S. Department of Energy's Fermi National Accelerator Laboratory, Brookhaven National Laboratory, and Lawrence Berkeley National Laboratory (Berkeley Lab) designed, built, and tested the new magnet.

It is one of 16 they will deliver for operation in the High-Luminosity Large Hadron Collider (HL-LHC) at CERN in Europe, which is an upgrade of the existing LHC -- already the world's most powerful particle accelerator. The 16 magnets, along with another eight produced by CERN, will focus beams of protons to a tiny spot as they approach collision inside two different particle detectors. The U.S.-based team will also deliver four spare magnets.

In all, the upgrade will require 130 new magnets of 11 different types, produced by more than a dozen international partners. The project will replace about three-quarters of a mile of equipment at the LHC.

Niobium-tin is the ingredient that sets these U.S.-produced magnets apart. It is a superconducting material that produces strong magnetic fields. These will be the first niobium-tin quadrupole magnets ever to operate in a particle accelerator.

Superconductivity is a state achieved by extremely cooling the magnets to a temperature hundreds of degrees below freezing. In this state, the magnets can pass electrical current with virtually no electrical resistance in order to maintain a tight focus of the particle beams.

The LHC is already the planet's most powerful particle accelerator, and its high-luminosity successor will smash together beams of protons cruising around the 17-mile ring at close to the speed of light.

The High-Luminosity LHC will pack an additional punch: With its more intense beams, it will provide 10 times the collisions that are possible at the current LHC. With more collisions there are more opportunities to uncover new physics. The new focusing magnets will help it achieve that leap in luminosity delivered to the experiments.

Berkeley Lab's work is focused on winding wires into thin cables, measuring and analyzing those cables to ensure they meet exacting requirements, testing the quality of the magnetic fields generated by the cable-formed magnet coils, assembling the magnets into support structures, and ensuring their proper alignment and uniform compactness.

Giorgio Apollinari, head of the three-lab U.S. LHC Accelerator Upgrade Project and a scientist at Fermilab, said, "We've demonstrated that this first quadrupole magnet behaves successfully and according to design, based on the multiyear development effort made possible by DOE investments in this new technology."

The magnet gets ready for a test at Brookhaven National Lab. [Photo: Brookhaven National Laboratory]

Kathleen Amm, Brookhaven Lab's representative for the Accelerator Upgrade Project, said, "It's a very cutting-edge magnet, really on the edge of magnet technology."

The new magnets, with higher field strength than those of the existing LHC, can bring particle beams to a tighter focus, resulting in more collisions that generate more data.

Focus, magnets, focus

In circular colliders, two beams of particles race around a ring in opposite directions. An instant before they reach the collision point, each beam passes through a series of magnets that focus the particle beams into a tiny spot, much like a magnifying glass focusing light rays to a point. Now packed as tightly as the magnets can get them, the beams collide.

Even with the new magnets, most of the particles won't collide; they continue their paths around the ring until they get another collision opportunity at the next detector. But many particles do smash into each other. That number, and the scientific fruitfulness of that smash-up, depends on how dense the beam is. The more particles that are crowded together at the collision point, the greater the chance of collisions.

You get those tightly packed beams by sharpening the magnet's focus. One way to do that is to widen the lens.

Consider the magnifying glass example: "If you try to focus the light from the sun using a magnifying glass at a small point, you want to have a more ‘powerful' magnifying glass," said Ian Pong, a Berkeley Lab scientist who oversees cable fabrication for the U.S. labs' magnet effort. A larger lens has more light-gathering ability and stronger light-ray bending power at its outer rim than a smaller lens.

In this analogy, the size of the lens is like a magnet's aperture -- the opening of the passageway the beam takes as it barrels through the magnet's interior. If the beam is allowed to start wide before being focused, more particles will arrive at the intended focal point -- the center of the particle detector. The U.S. focusing magnet team widened the aperture to 150 mm, more than double the current LHC focusing magnet aperture of 70 mm.

A magnet-testing instrument (center) is prepared for moving through the center of a magnet assembly at Berkeley Lab. [Credit: Marilyn Sargent/Berkeley Lab]

But a wider aperture isn't enough. There must be a strong magnetic field to actually focus the beam.

"The magnet has to squeeze the beam more powerfully than the LHC's present magnets in order to create the luminosity needed for the HL-LHC," Apollinari said.

Niobium-tin for the win

Magnet experts have been experimenting with one of those conductors, niobium-tin, for decades. Electrical current coursing through a niobium-tin superconductor can generate magnetic fields of 12 teslas -- about 250,000 times stronger than the Earth's magnetic field at its surface -- and beyond.

But niobium-tin calls for entirely different magnet construction techniques than the ones used with niobium-titanium, because the heat treatment that makes niobium-tin superconductive also makes it brittle.

"Once they're reacted, it becomes a beautiful superconductor that can carry a lot of current, but then it also becomes brittle," Apollinari said.

"If you bend it too much, even a little bit, once it's a reacted material, it sounds like corn flakes," Amm said. "You actually hear it break." Niobium-titanium was easier to work with because it is pliable.

Over the years, scientists and engineers have figured out how to produce a niobium-tin superconductor in a form that is useful. Guaranteeing that it would hold up as an HL-LHC focusing magnet was another challenge altogether.

To meet the demand, scientists designed and constructed a muscular focusing magnet. They calculated that, at the required aperture for the upgrade project, each focusing magnet would have to generate a field of between 11.4 and 12.4 teslas. This is up more than 50 percent from the 7.5-tesla field generated by the current niobium-titanium-based LHC magnets.

"So what do you do? You need to go to a different conductor," Apollinari said.

It takes state-of-the-art physics and engineering to make the magnets

To produce large, intricate magnets that meet the demands of a collider, the group of three U.S. labs teamed up -- each with its own areas of expertise and specialized facilities -- under Fermilab's leadership.

At Berkeley Lab, the magnet-making process begins by fabricating cable from 40 spools of wire -- a copper matrix that contains niobium and tin. The machine-wound wires are rolled into thin, rectangular cables that must be defect-free and meet specifications within hundredths of a millimeter.

"Making these accelerator magnet cables is like directing 40 ballet dancers doing 5,000 pirouettes nonstop in a synchronized manner, where a single misstep would cost as much as crashing a few Tesla sportscars," Pong said.

Scientists at Fermilab and Brookhaven wind these cables into coils, taking care to avoid excessively deforming them. Then comes a three-stage, week-long heat treatment, causing a chemical reaction that makes the cables superconductive.

The magnet coils must be heated evenly, inside and out. "You have to control the temperature well. Otherwise the reaction will not give us the best performance," Pong said. "It's a bit like cooking. It's not just to achieve the temperature in one part of the coil but in the entire coil, end to end, top to bottom -- the whole thing." Researchers make the coils strong and solid by embedding them in a resin.

It takes several months to yield a coil that is ready for service as one of a focusing magnet's four poles. Together, the coils conduct the electric current that produces the magnetic field.

The magnet coils are assembled within an aluminum and steel support structure at Berkeley Lab to form a single magnet, and researchers test the magnetic fields produced by these coils and ensure that the support structure provides uniform pressure along the length of the coils.

Temporary water-pressurized metal bladders are used to provide tension to the support structure during assembly and alignment. The support structure is designed to withstand more than 20 million lb of force during operation. Researchers use models and instruments to verify that the support structure can withstand the strength of the magnetic field.

"Because these coils are very powerful when they are energized, there is a lot of force trying to push the magnet apart," Pong said. "Even if the magnet is not deforming, at the conductor level there will be a strain, to which niobium-tin performance is very sensitive. The management of the stress is very, very important for these magnets."

Alignment of the four coils within each magnet is also critical to performance. "You need very high field precision, so we have to have very high precision in how they align these to get good magnetic-field uniformity," Amm said.

The full magnet is an eight-ton structure that's about as long as a semitruck trailer. The magnets are shipped to Brookhaven for testing, then to Fermilab for installation in their cryogenic containers, followed by another round of testing before shipment to CERN.

"This will be the first use of niobium-tin in focusing accelerator magnets, so it will be pretty exciting to see such a complex and sophisticated technology get implemented into a real machine," Amm said. "These magnets are currently the highest-field focusing magnets in accelerators as they exist today."

Pong added, "Finally we are coming to it, and we really want to make sure it is a lasting success."

The many moving parts of an accelerator collaboration

Ensuring lasting success has as much to do with the operational choreography as it does with the exquisite engineering. Conducting logistics that span years and a continent requires painstaking coordination.

"For example, transportation communication: We have to make sure that things are well protected," Pong said. "Otherwise, these expensive items can be damaged, so we have to foresee issues and prevent them."

Amm, Apollinari, and Pong acknowledge that the three-lab team has met the challenges capably, operating as a well-oiled machine.

"The technologies developed at Fermilab, Brookhaven, and Berkeley helped make the original LHC a success. And now again, these technologies out of the U.S. are really helping CERN be successful," Amm said. "It's a dream team, and it's an honor to be a part of it."

VIDEO: Highlights of the magnet-making efforts to support the High-Luminosity Large Hadron Collider upgrade at CERN in Europe are shown here. Three U.S. Department of Energy national labs -- Berkeley Lab, Fermilab, and Brookhaven Lab -- are building superconducting magnets that can produce far stronger magnet fields than the magnets now in place at the LHC. This will enable more particle collisions and data to help us learn more about exotic particles and their properties. [Credit: Marilyn Sargent/Berkeley Lab]

The team's achievements are made possible by many years of R&D. The U.S.-based Accelerator Upgrade Project for the HL-LHC, of which the focusing-magnet project is one aspect, began in 2016. It grew out of a 2003 predecessor, the U.S. LHC Accelerator Research Program (LARP), that developed LHC-related accelerator technology. And these efforts drew upon past experience in pushing the frontiers of magnet and materials performance for a variety of applications.

From now until about 2025, the U.S. labs will continue to build the LHC magnets, from fine strands of niobium-tin to the hulking finished products. In 2022 they plan to begin delivering the magnets to CERN. Installation is planned in the following three years.

"People say that ‘touch down' is a very beautiful way to describe the landing of an airplane, because you have a huge metal object weighing hundreds of tons, descending from the sky, touching a concrete runway very gently," Pong said. "Our magnets are massive superconducting devices, focusing tiny, invisible particle beams that are flying close to the speed of light through the bore. It's quite magical."

The magic starts in 2027, when the High-Luminosity LHC comes online.

The work, Apollinari said, is "a generational passing of the baton."

"The upgrade project exemplifies what can be achieved through co-operation among the laboratories," said Associate Laboratory Director James Symons. "The U.S. contribution to the luminosity upgrade has been made possible by the very successful LARP collaboration, which developed the design concept over the past decade."

Sources: Fermi Lab, Berkeley Lab

Published March 2020

Rate this article

View our terms of use and privacy policy