| November 18, 2014 | Volume 10 Issue 43 |

|

| 2015 COOL PARTS CALENDAR

Designed by designers and engineered for engineers, our annual Cool Parts Calendar features the visions of product developers across the nation and around the world. It features monthly contests, industry tradeshow dates, and (of course) those elusive days of the week.

Request your calendar today. |

| | Feature articles |

| The expanding use of angle position sensing

Application designers are always looking for ways to expand their capabilities and reduce design challenges. Angle position sensors have become increasingly popular for providing these objectives in the design process. Ryan Eder from CHERRY Industrial Solutions runs us through the basics.

Read the full article. |

|

| Piezo motor technology: Questions answered

There's a new kind of piezo motor in town, and it's got legs. The Piezo LEGS® rotational motor is a direct-friction drive that provides precise motion without any mechanical play or backlash. There are no gears or transmission, so changing the direction of the motion will introduce no error. The simple Piezo LEGS® motor is also extremely stiff. Find out the answers to frequently asked questions about this exciting new motor technology.

Read the full article. |

| Wings:

LabVIEW and NI CompactDAQ get the Skylon space plane project off the ground

Current space propulsion systems based on rocket technology alone place limits on the performance of launch vehicles, which leads to multistage vehicle configurations that are either expendable or only partly reusable. This results in complex launch systems that are both high maintenance and expensive to operate. REL's Skylon space plane, a fully reusable single-stage launch vehicle, addresses these drawbacks and could revolutionize future access to space by providing more efficient and reliable launch operations. Michael Hood of Reaction Engines Ltd. talks about developing and testing the Skylon Mach 25 engines.

Read the full article. |

| Plastic bearings have staying power

Plastic bearings are strong enough to outperform and outlast metal in countless applications. Plastic bearings are an economical replacement for needle, ball, and plain metal bearings. However, they are often not considered a viable choice in the engineering community due to the common misconception that plastic is inferior or weaker compared to metal. Uncover common misconceptions and learn the true reliability of plastic bearings in this new igus® whitepaper.

Click here to go to the whitepaper -- no registration required. |

| Mike Likes:

Change the phase relationship of a drive component and the shaft easily

It's easy to change the phase relationship of a drive component and the shaft with a Phas-Lok from Zero-Max. Designed to reduce system downtime, these labor-saving devices eliminate the need to disconnect or remove drive components in order to reposition or re-synchronize them. They provide an accurate, mechanical adjustment with a 24-degree range (+/- 12 degrees) and compensate for required timing changes in a power transmission system. When mounted in a system, the Phas-Lok acts as a dependable position control device. It is ideal for fine-tuning timing adjustments, including adjusting for chain elongation and sprocket tooth wear. Available in three sizes.

Click here to learn more. |

| Product: Ergonomic height-adjustment system

The ErgoSwiss TQ System is perfect for desks and workstations, assembly and folding tables, kitchen counter tops, sinks and cabinets, displays, flow hoods, abrasive blast cabinets, biological cabinets, fume hoods, and conveyors. The TQ leg has an extruded aluminum profile with a stainless steel tube mounted inside. The lifting movement is provided by hydraulic cylinders. The 8-mm-wide T-Slots allow interim shelves, fittings, and attachments to be fitted the whole length of the table leg. The system is available in single parts or as a complete sub-frame. It is adjusted using a hydraulic pump with a hand crank or an electric drive. Available from American Sales Development.

Click here to learn more. |

| Product: New gearbox sizing tool

GAM's new Sizing Tool makes it easy to find the right gear reducer, coupling, or linear mount product compatible with your motor. Simply select your motor, adjust the ratings based on the application, and narrow down the products that match. Over 9,000 of the most popular servomotors on the market are available for selection. After choosing a motor, easily narrow down the list of matching products by filtering attributes.

Click here to learn more. |

| Software: Build, deploy specialized apps in COMSOL

What if you could run your multiphysics simulations as specialized applications? Now you can. Included in COMSOL Multiphysics when you update to version 5.0 is the Application Builder, which lets you build applications based on your COMSOL Multiphysics models. Applications enable accessing models with specialized and intuitive user interfaces that can be used by anyone throughout your organization, leveraging your simulation expertise and providing far greater access to the power of COMSOL Multiphysics. Your apps can include any physics and multiphysics combinations from the COMSOL product suite for mechanical, electrical, fluid, and chemical simulations.

Click here to learn more. |

| | Videos+: Technologies and inspiration in action | Can you get more out of a cheap motor?

When buying expensive motors, you typically pay for a more optimized design, higher quality materials, and higher quality manufacturing. Researchers at the University of Pennsylvania's MODLAB claim that you can compensate for the usual shortcomings of a cheap motor by mapping the motor's torque ripple and feeding in the inverse of this map to the motor's produced torque via software, making an anticogged motor. The torque ripple ratio is significantly decreased for the motor, and a cheap motor can now perform as good as an expensive one. What do you think? For the time being, we are sticking with, "You get what you pay for."

View the video. |

|

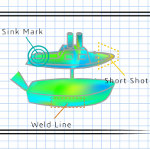

Fundamentals of SOLIDWORKS Plastics

Validating your plastic part designs with SOLIDWORKS Plastics will ensure proper fill, determine best gate location, and eliminate potential defects and improve part quality. Take a look at this intro to the software.

View the video. |

|

|

|