| September 29, 2020 | Volume 16 Issue 37 |

| Robot Ready: How automation is driving the future of fastener installation

Robotic automation is the biggest way in which fastener installation equipment has changed in recent years. The Haeger® line of insertion systems, part of the PennEngineering® family of brands since 2018, is a great example of technology that utilizes robotic automation to insert nearly every type and size of self-clinching fastener out there. Learn all about this capable and flexible system. An example cost study is included.

Read the full article. |

| Cool Tools: Easy-setup orbital sander for cobots launched by OnRobot

The new Sander package from OnRobot includes everything customers need to get their robotic sanding application started quickly and easily: a plug-and-play sanding tool, a variety of standard 3M sanding and polishing pads, easy-to-use programming software, an optional force/torque sensor, and a Grit Changer that enables automated switching between different sanding grits without operator intervention. All of the advanced features are supported on Universal Robots cobots, but the tool is easily integrated with any major robot brand.

Read the full article. |

| Jet fighters and BMWs: Trends in manufacturing

At a new facility in Warton, Lancashire, BAE Systems is applying game-changing digital technologies to advance manufacturing of the UK's next-gen combat jet fighter called Tempest. Their updated toolbox includes a digitally connected intelligent factory, digital twins, automated robots and cobotic technologies, and intelligent workstations. Carmaker BMW in Germany is updating its factories and process tech too, focusing on using augmented reality in prototyping and building a new 3D-printing tech center in Munich.

Read the full article. |

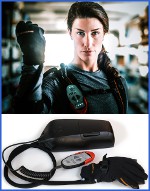

| Ironhand powered glove keeps workers healthy and efficient

The Ironhand system is the world's first active soft exoskeleton for the hand. It was designed and produced by Swedish company Bioservo Technologies to improve the health of workers who perform grasp-intensive and repetitive tasks. To control the individual fingers, pressure sensors in the glove fingertips detect the gripping action, and an integrated computer calculates the additional force necessary. Powerful micro-servomotors from FAULHABER pull thin cables in the glove fingers to provide up to 80 N of gripping force throughout the workday.

Read the full article. |

| Cobot with vision camera inspects engine sub-assemblies

When you're assembling a part of a car's engine that controls the power steering, you have no choice but to be perfect. Anything less than 100% quality could result in a tragic failure. To meet that expectation, Comprehensive Logistics receives a helping hand -- from a Universal Robots cobot arm that can see.

Read the full article. |

| Solutions for robotic pick and place, packaging automation

FANUC America's team of authorized system integrators provide turnkey solutions that help both small and large customers quickly respond to market demands in a wide range of industries and applications. If you're considering automation, FANUC can help you address any challenge you face. Learn about Easy Robotic Picking and Packaging Customization, Robotic Sorting and Picking, Food-Safe Robots, Robot Types, and more.

Learn more. |

| How to choose the right robot

Robots come in many sizes and configurations, with two to seven axes, and can do simple or complicated work. For both factory and process automation, there's one to suit just about any application or budget. Engineers at Festo take a calculated and thoughtful approach to helping you in your selection process in this informative whitepaper (no registration required). They cover different types of robot tech, benefits and limitations, extra factors to consider, and more.

Learn more. |

| Compact ServoWeld actuators for robotics

The latest generation of Tolomatic high-force actuators for seventh-axis robotic spot-welding is now designed on a compact footprint in Tolomatic's most power-dense actuator for weld-gun designs. Compact ServoWeld actuators, available in two patent-pending models, are designed for automotive body-in-white resistance spot welding as well as high-production sheet-metal welding applications. The compact servo motor and high-force actuator combo can deliver up to 30 million welds (CSWX model) in typical robotic welding applications, along with increased force and speed capabilities.

Learn more. |

| 7th axis quickly extends range for robots

igus now offers a ready-to-connect 7th axis that will allow robots from robolink and Universal Robots to move over a distance of several meters. The 7th axis is supplied by igus as a complete system that is ready to connect immediately, consisting of a drylin ZLW-20 toothed belt axis in the desired length exactly to the millimeter, plus the connecting cables, the switch cabinet, the power electronics, the software integration, and the corresponding adapter set.

Learn more. |

| Fastest packaging machine: 2x speed in same footprint

Norwegian machine builder Tronrud Engineering worked with Siemens to develop an innovative, all-electric machine that can pack 300 pillow-shape bags per minute -- the fastest of its kind. During development, the project team used Teamcenter, NX Mechatronics Concept Designer, and the Totally Integrated Automation Portal as well as SIMATIC S7-PLCSIM Advanced to create a digital twin. Tronrud managed to reduce the design phase by 10% and commissioning time by 25%, which led to a significantly shorter time to market.

View the video. Very informative regarding industry trends. |

| Replace traditional mechanical fasteners in assembly with 3M tape

Since 1980, 3M VHB Tapes have opened the door to faster and easier assemblies. These tapes, including the new GPH series with high-temperature resistance, replace traditional mechanical fasteners, eliminating processes like drilling, grinding, refinishing, screwing, welding, and associated rework/clean-up. Automated Taping Systems are available through 3M partners.

Learn more. |

| Function-integrated machine frames from Rexroth include internal cable guide

Bosch Rexroth's new function-integrated profiles (FIPs) include a completely internal cable guide that allows for the safe and space-saving laying of cables, data lines, and hoses. Thanks to the new profile junctions, they can even be laid through profile connectors. The FIP range comprises four profile cross-sections with a host of accessories to build on the modular system. The entire solution can be combined with the established Rexroth modular profile system and provides an unprecedented level of design flexibility.

Learn more. |

| | Most popular last issue |

| 50 ways to use a hexapod

Hexapods, six-legged parallel-kinematic machines, can solve many complex positioning and alignment tasks in fields including Optics, Photonics, Precision Automation, Automotive, and Medical Engineering. Features include a programmable pivot point, sub-micron precision, and load capacities from 2 to 2,000 kg.

Learn more from PI. |

| New PLC handbook chock full of must-know information

AutomationDirect's Practical Guide to Programmable Logic Controllers Handbook has been improved with tons of new need-to-know info, making it a more comprehensive guide to the world of PLCs. Besides covering the basics of PLC history, PLC hardware, and PLC software, this guide takes you deeper into the ever-changing world of PLC communication, the importance of feedback loops, cyber security, and many other areas that are a must-know for any PLC novice or seasoned automation professional.

Get this great resource today. |

|

| | Videos+: Technologies and inspiration in action | Ice Blast cleans and deburs parts

When you mix an IceStorm machine from Coulson Ice Blast with a KUKA articulated robot, you get a neat and efficient system that carries out cleaning, deburring, and deflashing of metal parts automatically -- using real ice (the same type of ice cubes you can put in your drink). The combination of pressurized air and wet ice in the blast stream allows for a non-toxic and non-abrasive process. There is a dry ice option too. Many more applications.

View the video.

Learn all the things this system can do. |

|

GE Aviation saves $1.3M in first year with automation

When the GE Aviation Asheville plant was searching for a way to increase productivity and scalability, the company looked at stationary robotics, robots on autonomous guided vehicles, mobile machine tending, ways to perform inspections, and even the overall plant software. A big part of their success has come in finding myriad, autonomous ways to move things around, including equipment, materials, products, and tools and systems. See what they've accomplished with the help of a suite of vendors.

View the video posted by OTTO Motors. |

|

Huge drivable robot may start a new sport

Obstacle course racing may never be the same if a team of robo-machine enthusiasts has its way. Inventor Jonathan Tippett, co-founder of Furrion Exo-Bionics, and industry and academic partners have created the 14-ft-tall, 8,300-lb, all-electric bionic racer called Prothesis. The aim is to develop a new all-terrain exo-bionic racing vehicle, where the movements of the pilot's limbs control the machine. The machine is essentially a massive exoskeleton -- part tank, part dinosaur.

View the video. |

|

|

|