Matching design intent with process capability:

Leveraging knowledge in the aerospace and defense industry

In a 1991 interview, Harry Hillaker, the “Father of the F-16,” spoke about technology and engineering, noting “there have been debates through the years about just how much technology should be incorporated in any design. The real issue isn't technology versus no technology. It is how to apply technology.” [U.S. Air Force photo: Master Sgt. John Nimmo Sr.]

It wasn’t that long ago that the most sophisticated design tools for aerospace systems were a T square and French curve. The accepted business practice at the time was to throw the drawing generated from these tools “over the wall” to manufacturing, which somehow made them into airplanes, missiles, and the full range of aerospace and defense products. These relatively primitive tools and practices didn’t mean primitive solutions. Airplanes that are still flying and will fly for another generation (B-52s, A-10s, and C-130s), were the products of this system. More recently, the F-16 was the product of slightly more advanced design tools and practices, but its engineering innovations (fly-by-wire) and technical challenges (high thrust-to-weight without sacrificing range) set high standards for its successors. In addition to its technical innovations, the F-16 was affordable and producible, helping to make it a mainstay for not only the U.S. Air Force, but for air forces around the world.

Since the F-16, the aerospace and defense industry has experienced huge gains in both design tools and business practices. In terms of practices, industry members have made extensive investment in lean and six sigma, adopting these acknowledged best practices as a fundamental part of the way they do business. CAD tools are now applied across the industry, and new aerospace systems are touted as being the products of a fully model-based design environment. A casual observer of the industry would draw the natural conclusion that — with such exceptional tools and practices in hand — today’s systems must be achieving all of their performance, cost, and schedule goals, leaving yesterday’s success stories like the F-16 in the dust.

Yet today’s major programs all too often exceed cost and experience delays. The GAO’s March 2008 Assessment of Selected Weapon Programs identifies extensive cost overruns and delays for numerous major weapon systems — just as the past five such reports have. The civil aviation side is not immune from similar problems, as recent well-publicized issues for major U.S. and European commercial aircraft programs illustrate. Based on this track record, given the widespread application of sophisticated design tools and best practices, the next logical observation is that the industry has somehow forgotten the smart things it did with lesser capability on programs like the F-16.

Analysis of these problems raises questions about current approaches to best practices and how they might be improved. One impediment is the difficulty in capturing fundamental knowledge of design practices/constraints and process capability at the component part level. Without a clear grasp of such knowledge, it is virtually impossible to apply it early enough in the product lifecycle so that downstream problems are avoided during production. Another potential shortfall is the level of rigor and discipline applied to detailed product understanding over the product lifecycle. The concept of characteristic-level accountability is an important aspect of current aerospace industry quality standards, including AS9100, AS9102, and AS9103, which address quality systems, first article inspections, and management of key characteristics, respectively. Finally, there is the need to effectively flow essential design and process requirements through multiple tiers of a supply chain that is growing in both size and level of responsibility.

Characteristic accountability — an important consideration

It has been observed that characteristic understanding is to product definition as atoms are to physics. A product is the sum of the dimensions, geometries, notes, and specification references that define what it is, how it will perform, how it must be made, and how it will fit with the next higher assembly. Depending on the product, characteristics might go beyond physical attributes to include such things as input/output relationships. Characteristics are discretely measurable and comprise the building blocks that create product features — if a hole is a feature, the diameter, depth, and surface finish of the hole are its characteristics. Individual part characteristics are the center point where design intent and process capability come together. They form the bridge between abstract design and tangible hardware.

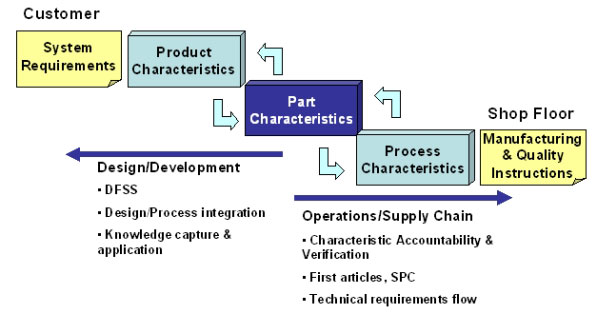

|

|

As the illustration shows, a discrete part’s characteristics are determined by its relationship to the larger product, which is the result of the overall system requirements. Returning to the F-16, the thrust-to-weight and range system requirements impacted design considerations such as size and drag, leading to very specific characteristics at the component part level. Converting these part characteristics into a real part is a factor of how capable the selected processes are in efficiently making this conversion. Starting with the part and its characteristics, it is possible to look upstream at the design/development process and downstream at the operations/supply chain process. The upstream process is one of knowledge capture and application; the downstream process is one of knowledge execution. Both are dependent on a clear understanding of characteristics and their relationships to design requirements and process capability, coupled with a disciplined approach to making those relationships work.

A practical approach: Bring design needs and process capability together

A quick Web search reveals that virtually every major aerospace company is pursuing Design for Six Sigma (DFSS) or one of its variants. Design for Manufacturing & Assembly (DFMA) and the Model Based Enterprise (MBE) are two prominent approaches to achieving integration between design and manufacturing in pursuit of the DFSS vision. Many of the top aerospace companies are on the leading edge of these efforts.

In examining the typical examples provided by advocates of MBE, it appears that if MBE is geared to enabling DFMA, there is considerably more emphasis on the “A” than the “M.” The highlighted MBE successes tend to focus on what appear to be post-design activities at the part level, emphasizing how components come together for higher assemblies, ergonomic factors, and interference avoidance. These are very important considerations, but they do not explain the creation of a model that yields a producible design at the part level.

Part level producibility is the key to product performance and affordability. An assembly might come together seamlessly through the use of models, but the individual components that make up the assembly drive performance, schedule, and affordability. As companies have begun to recognize this, they realize that achieving their DFSS or DFMA objectives at the part level depends on three factors:

- Knowledge capture and reuse. The understanding of process capabilities and limitations, and the documentation of known design practices and constraints are essential pieces of knowledge that are seldom well documented. This captured knowledge, when coupled with a common interpretation, consistent application, and ease of access/reuse provides a common starting point during design.

- Knowledge application. Having the necessary knowledge is a good start. Applying and integrating it so that characteristic-level process capability can be weighed against design requirements is a critical step in the realization of DFSS.

- Knowledge exchange. The ability to take the knowledge, apply it in such a way that informed decisions can be made, and adjust accordingly is a function of collaborative exchange. However, to be effective, exchange among the disciplines involved in product development must be timely and integral to the process.

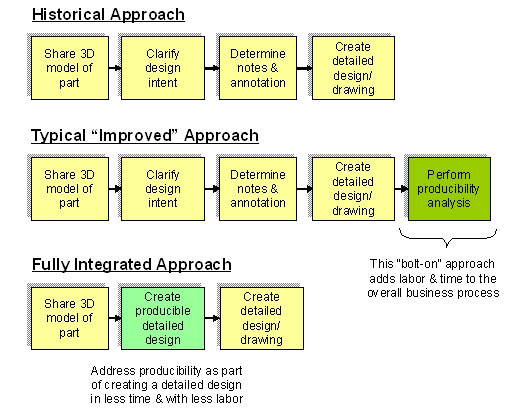

Making this happen at the part level requires discipline and commitment to the process that is often missing even in the Model Based Enterprise. Bringing manufacturing engineers into the design process is a popular concept. It is where and when they enter the process that determines their effectiveness. The historical approach of “throwing the design over the wall” has clearly lost favor. The more recent — and more enlightened — approach provides for a producibility assessment, but often near the end of the design process, as a “bolt-on” activity during an obligatory tollgate review. This approach has limitations, because the manufacturing input often means changes to the design, which in effect creates “rework” for the design engineer. The bolt-on approach, while better than no manufacturing input, does not represent a truly integral collaborative exchange process. Making the manufacturing engineer integral to the process is clearly the best approach, but it is also challenging — both culturally and technically. The next illustration highlights the three approaches.

|

|

By merging the best of the Model Based Enterprise’s technical promise with an enlightened design process, the three factors of knowledge capture and reuse, application, and exchange can come together seamlessly at the component part level. The enabling technology for this merger is evolving as new software products become available.

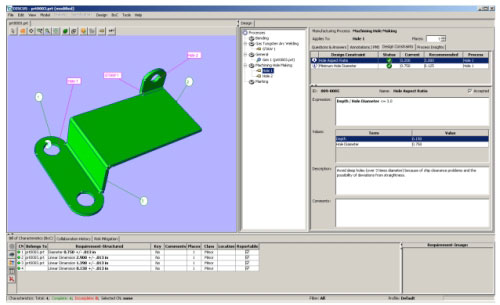

Such a software product can serve as the technical platform for integration of process knowledge and design practices, providing for component part characteristic-level DFMA — with an emphasis on the “M” — in a Model Based Enterprise. Ideally, such a system is “CAD neutral,” allowing the manufacturing engineer to receive, evaluate, and annotate a solid model image during that dynamic period when a part approaches detailed design, but before it is too late to make meaningful suggestions. Using the combined design and manufacturing knowledge, the system can both store and dispense essential process insights, specification references that apply to individual processes, and design constraints. It then enables the application of this knowledge as direct characteristic-level annotations to the model. These annotations are then systematically captured in a “bill of characteristics” that allows them to be managed going forward over the product lifecycle.

One such system, known as DISCUS Design, has been applied in some pilot applications. During these initial applications, the software demonstrated increased engineering productivity, shorter cycles, and designs that are ready for transition and affordable production. By bringing together best practices in both the technological and cultural aspects of product development, such a system offers a practical approach to DFSS, with results that support the goals of product performance and affordability.

|

|

Understanding of fundamentals is essential — characteristic accountability is key

In a 1991 interview, Harry Hillaker, the “Father of the F-16,” spoke about technology and engineering, noting “there have been debates through the years about just how much technology should be incorporated in any design. The real issue isn't technology versus no technology. It is how to apply technology.” This wisdom is applicable not only to design, but to the technologies used to convey the design. It is this understanding of the fundamentals of the technology — its promise, shortcomings, and relationship to the larger system — that is essential to success as systems grow in complexity and sophistication. Today we have the advantage of tools and practices that were unheard of even as recently as when the F-16 was developed. But if we do not apply them to their full advantage, aerospace and defense programs will continue to experience cost growth and program delays.

The Model Based Enterprise is clearly the direction of the future. However, as the GAO report and recent civil aviation experiences have shown, there is still a long way to go. Anyone looking for a silver bullet is in the wrong business. The fundamentals of characteristic accountability — starting early and continuing over the full product lifecycle — are where the journey begins and ends. As the successful application of emerging software tools and methodologies indicates, the disciplined merger of knowledge and attention to the characteristic-level details remain the essential elements in realization of design intent, process capability, and ultimately system affordability.

About the author

Robert Morris is a Partner in Renaissance Services. His activities include the program definition and analytical activity associated with application of advanced systems for management of specifications and design characteristics to meet emerging engineering, manufacturing, and quality standards. He was formerly Vice President of Military Products Division at O’Gara-Hess and Manager of Technical Programs Development at GE Aircraft Engines. He is currently a member of the Executive Committee of the Supplier Management Council of the Aerospace Industries Association (AIA). BS from the Ohio State University and Honor Graduate of the Air Force Institute of Technology Production Management Program. He can be reached at bmorris@ren-services.com.

Want more information? Click below.

DISCUS Software

© Nelson Publishing, Inc. All Rights Reserved